Equipment for adhering sand paint on end parts of chopsticks

A technology of chopsticks and equipment, applied in the field of chopsticks processing, can solve problems such as low efficiency of manual work, and achieve the effects of smooth sand dipping, improving efficiency and saving work time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

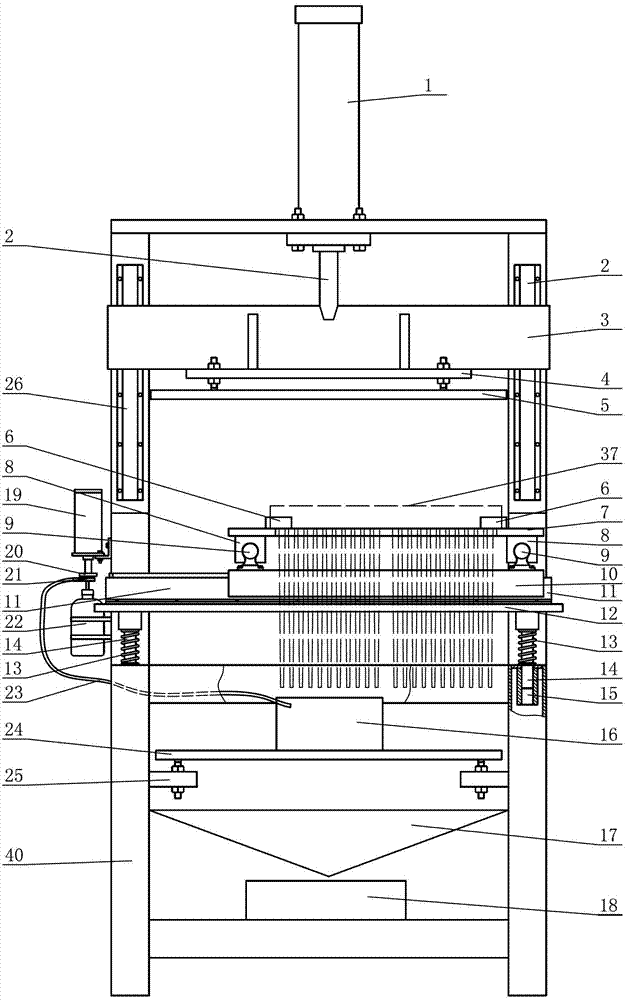

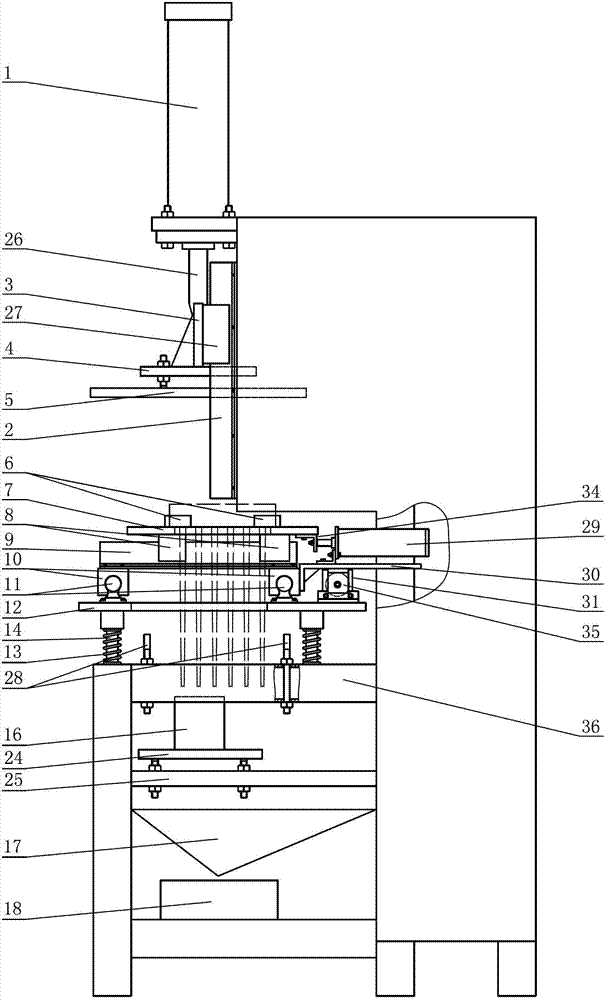

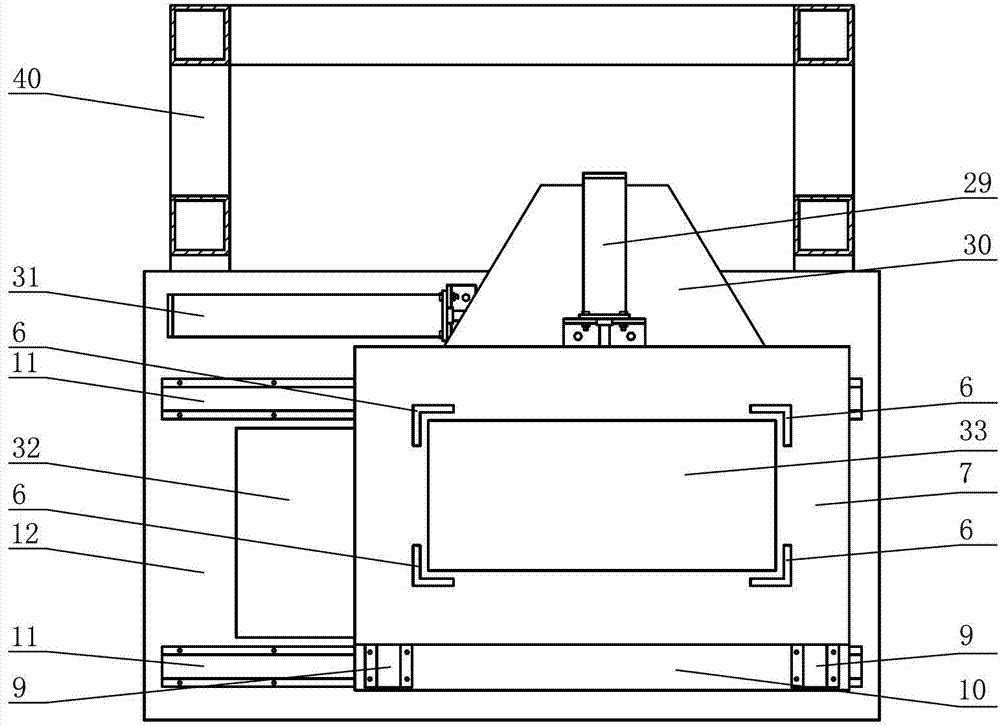

[0039] The device of the present invention will be further described below in conjunction with a specific embodiment.

[0040] refer to Figure 1-4 , in this example, the device of the present invention includes a square frame-shaped base 12 that can be lifted and lowered on the frame 40, and a square frame-shaped top seat 7 that is arranged above the base. Corresponding to four corners below the base, a cylindrical guide rail 14 is vertically fixed, and the lower ends of the four cylindrical guide rails are respectively assembled in four sliding sleeves 15 on the frame. A compression spring 13 is set on every cylindrical guide rail, the lower end of the compression spring is pressed against the frame, and the upper end is against the bottom of the base. Below the left and right borders of the corresponding base on the frame, there are four space-limiting push rods 28 altogether. The parts corresponding to the upper and lower sides of the beam 36 are respectively fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com