Splitter plate of rubber extruding filter

A diverter plate and rubber filter technology, which is applied in the field of diverter plate of rubber extrusion filter machine, to achieve the effect of reducing head pressure, reducing power consumption and avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

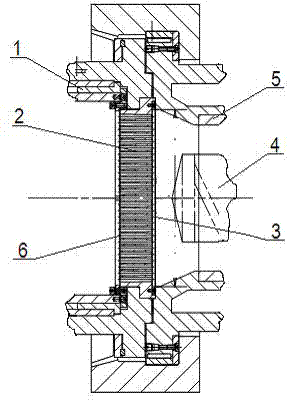

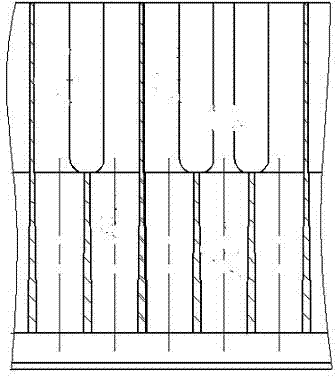

[0014] Such as figure 1 and figure 2 As shown, the splitter plate of the rubber extrusion filter machine includes the head 1, the splitter plate 2, the filter screen 3, the screw 4, the barrel 5, and the splitter plate opening 6. The head 1 is connected to the barrel 5, and the screw 4 is in the Inside the barrel 5 and there is a certain gap with the barrel 5, the diverter plate 2 is embedded in the head 1 of the rubber filter machine, the rubber extruded by the screw 4 in the barrel 5 is filtered through the filter 3, and the filter 3 is divided by the diverter The plate 2 is supported and fixed, and the rubber material enters the distribution plate 2 after passing through the filter screen 3. When the rubber material enters the opening 6 of the distribution plate, the pressure is released quickly, and the rubber material passes through the distribution plate 2 smoothly and enters the next process. The opening structure of the splitter plate in the invention is simple, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com