Airplane nose wheel gripping device

A technology of holding clips and nose wheels, which is applied in the field of aircraft nose wheel holding devices. It can solve the problems of easy existence of nose wheels, unstable state of holding clips, and unstable center of nose wheels, so as to achieve stable center of nose wheels and meet traction requirements. , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

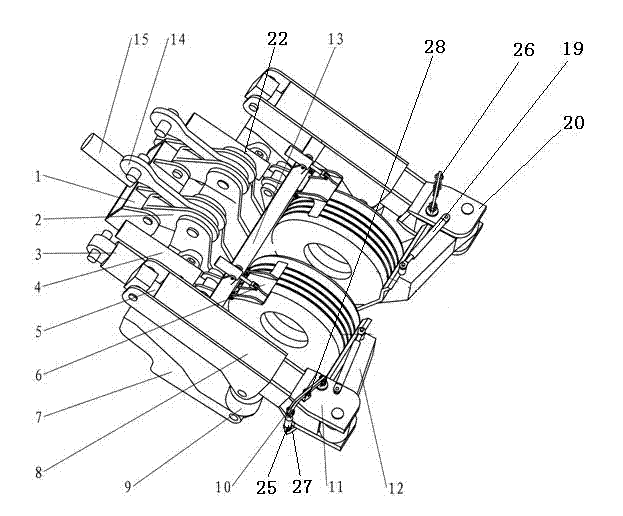

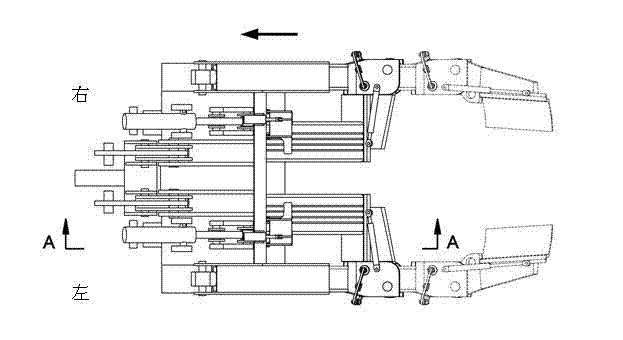

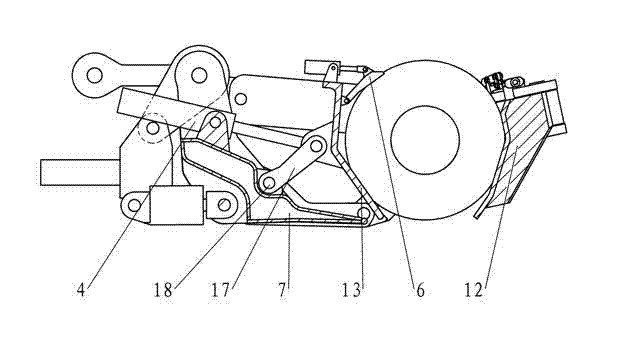

[0024] Below in conjunction with accompanying drawing, the present invention is further described:

[0025]As shown in the accompanying drawings, an aircraft nose wheel clamping device, including a vehicle frame, is characterized in that it is provided with a swing frame 1, a lifting cylinder 3, a turning cylinder 4, a telescopic cylinder 5, a main clamping platform 7, a secondary clamping Platform 13, upper tie rod 14, lower link 2, telescopic sleeve 8, telescopic arm 11, rotating pin 15, hinge pin 16, clamp 12, height adjustment cylinder 9, main and auxiliary platform pull rod 17, clamping cylinder 19 And the locking mechanism 10, the swing frame 1 is hinged with the vehicle frame through the rotating pin shaft 15 in the center, the main holding clip platform 7 is arranged at the rear of the swing frame 1, and the upper end of the front part of the main holding clip platform 7 is arranged successively along the center to both sides. There are support frame 22 and flipping oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com