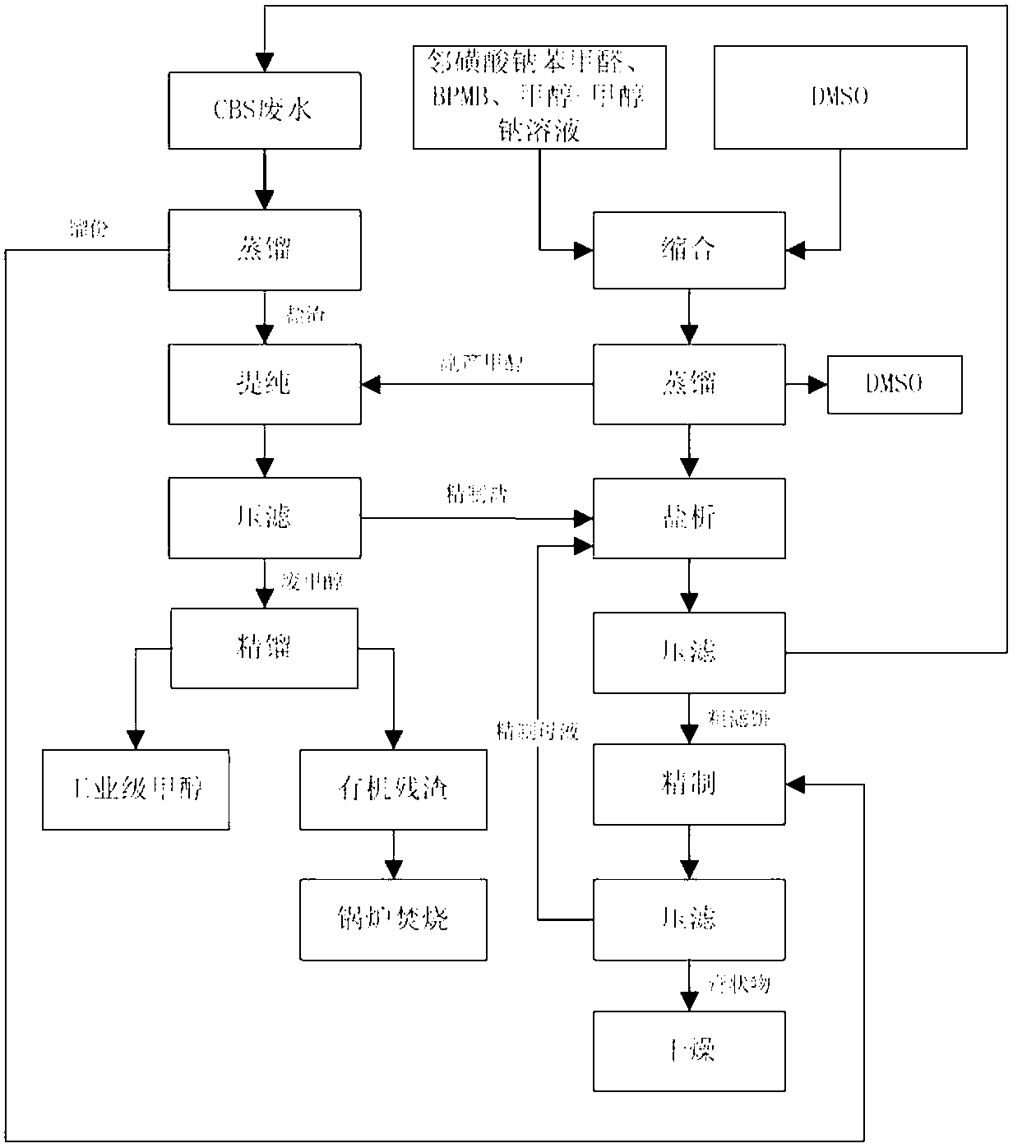

Method for processing and recycling production wastewater of fluorescent brightener CBS

A fluorescent whitening agent and waste water production technology, applied in heating water/sewage treatment, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as decline in treatment effect, large increase in waste water volume, consumption of water resources, etc., to achieve The effect of low processing cost, excellent effect and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

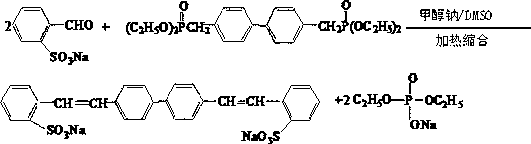

Method used

Image

Examples

Embodiment 1

[0025] Test 1: Take 5000 grams of normal batch of CBS production wastewater, put it in a four-necked flask, and use atmospheric pressure distillation to collect fractions during the distillation process. After the distillation, 4875 grams of fractions and 125 grams of salt residue are obtained.

[0026] Put the salt slag into a 1000ml four-neck flask, add 500 grams of by-product methanol from the CBS production distillation section, stir for 30 minutes to completely disperse the salt slag in the methanol, filter through a Buchner funnel to obtain 110 grams of refined salt and 515 grams of waste methanol gram. Waste methanol was rectified to obtain 480 grams of methanol and 35 grams of organic residue.

[0027] The methanol obtained by rectification is detected by gas chromatography, and the content is 99.2%.

[0028] Experiment 2: The distillate and refined salt recovered from Experiment 1 were used in the synthesis of CBS in the laboratory, and the obtained CBS product was 1...

Embodiment 2

[0034] Using the MVR system (configured with the steam compressor produced by the American Tessel Corporation and the forced circulation evaporation crystallizer), 2000 kg of CBS production wastewater is distilled, 1950 kg of distillate is recovered, and the remaining salt residue in the evaporator is 50 kg.

[0035] Add 200 kg of by-product methanol recovered from the CBS production distillation section to a 1 cubic enamel kettle, start stirring, then put 50 kg of salt slag into the kettle, stir for 30 minutes to fully disperse the salt slag in the methanol, and press filter to obtain 44 kg of refined salt, 206 kg of waste methanol, 192 kg of methanol and 14 kg of organic residue after rectification of waste methanol.

[0036] The methanol obtained by rectification is detected by gas chromatography, and the content is 99.3%.

[0037] Using the MVR system to treat wastewater, the power consumption cost is about 45 yuan / ton.

Embodiment 3

[0039] 2000 kg of CBS wastewater was treated by atmospheric distillation, and other operations were the same as in Example 2. Atmospheric distillation treats wastewater, and the power consumption cost is about 300 yuan / ton.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap