EPS (expandable polystyrene) sewage treatment aerator

A sewage treatment and aerator technology, applied in the field of water treatment, can solve the problems of inconvenient operation, high cost, easy damage of the aeration head, etc., and achieve the effect of convenient operation, low cost, and increased air outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

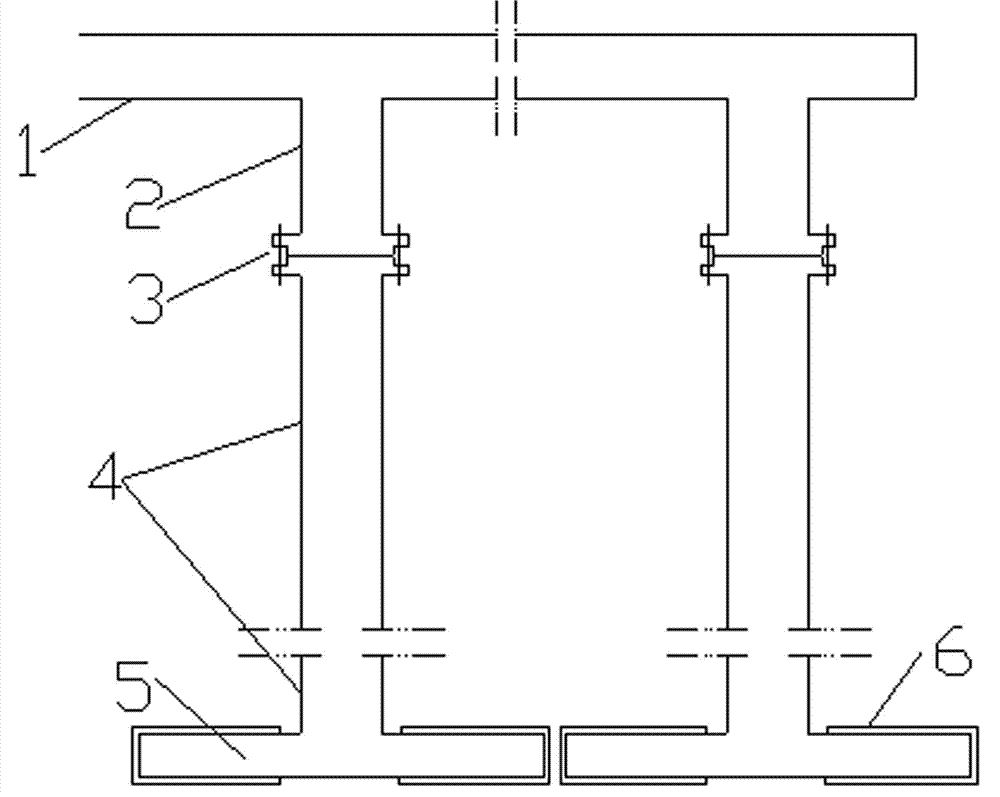

[0013] As shown in the drawings, the aerator for EPS sewage treatment includes multiple rows of air supply pipes 1 arranged above the strain pool, and a plurality of connecting pipes 2 are evenly spaced on the air supply pipes 1, and each connecting pipe 2 Connect the air supply tee pipe 4 through the flange 3, the air supply tee pipe 4 is T-shaped, and stretches vertically to the bottom of the pool, and the two horizontal ports of the air supply tee pipe 4 are respectively connected with a microporous aeration pipe 5. The porous aeration tube 5 is a hollow tube densely covered with micropores. The microporous aeration tube 5 is covered with a microporous aeration membrane 6 , and the microporous aeration membrane 6 is also correspondingly provided with densely distributed micropores.

[0014] The connecting pipe 2 can be a threaded three-way pipe, or can be integrally made with the air supply pipe 1 .

[0015] When in use, referring to the accompanying drawings, the oxygen-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com