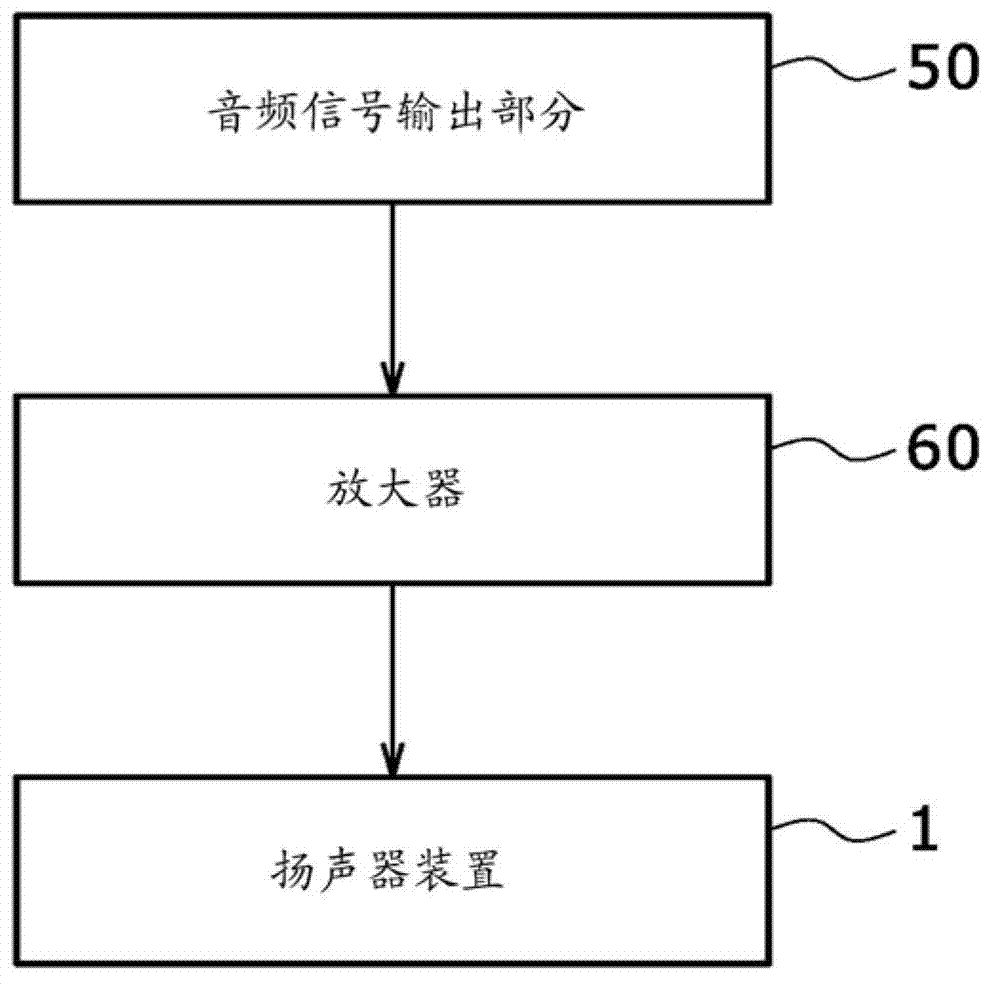

Speaker device

A loudspeaker and magnetic pole technology, which is applied in the field of loudspeaker devices and improved sound quality, can solve the problems of loudspeaker devices due to heavy dampers and reduced sound conversion efficiency, and achieve the effect of improving sound quality and sound conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

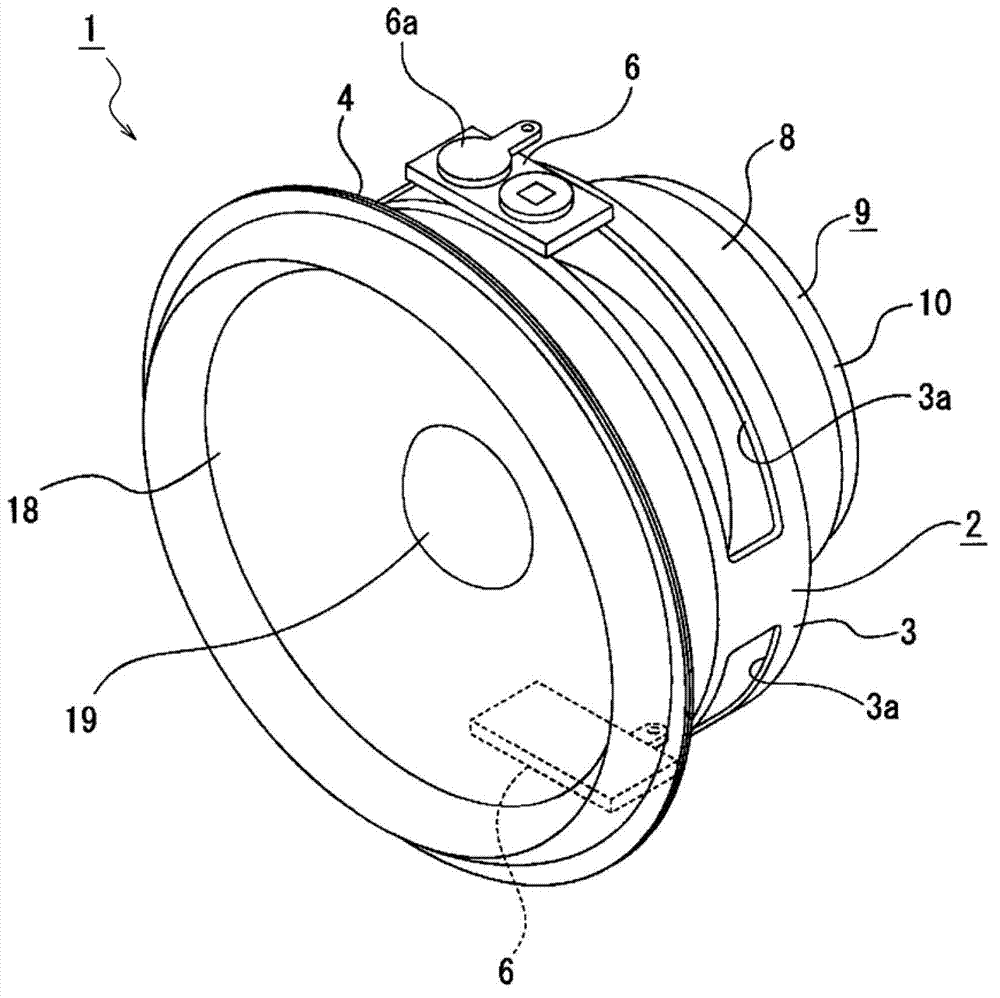

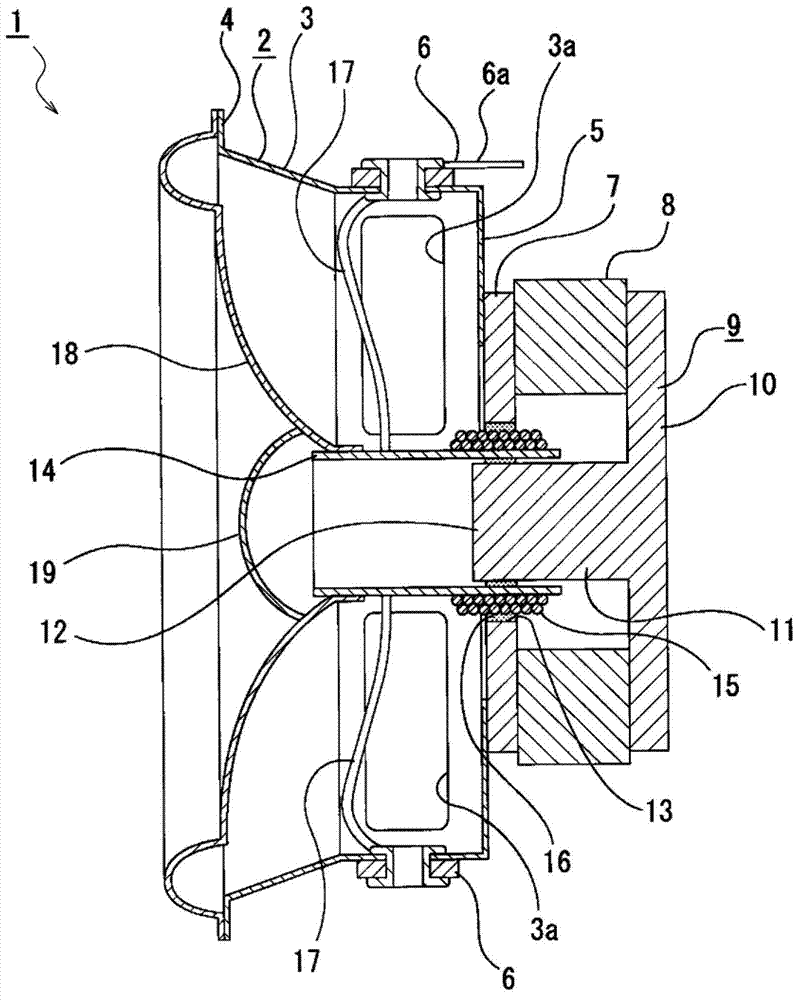

example 1

[0166] Next, a modified example of the magnetic flux changing portion adapted to form a magnetic field gradient in the circumferential direction of the center pole portion of the yoke (see Figures 15 to 18 ).

[0167] It should be noted that the magnetic flux changing portion according to the modified example as shown below is formed on the plate or the center pole portion of the yoke. In the description given below, only the differences from the plate 7 and the center pole portion 11 will be described. Plates or center pole portions similar to those of the speaker device 1 described above are denoted by the same reference numerals, and descriptions thereof are omitted.

[0168]

[0169] For example, six recesses are formed on the inner peripheral surface of the plate 7, spaced equidistantly from each other in the circumferential direction. According to the first modified example, each of these recesses is formed as the magnetic flux changing portion 7a (see Figure 15 )...

example 2

[0189] Next, a modified example of the magnetic flux changing portion, which is adapted to form a magnetic field gradient in the axial direction of the center pole portion of the yoke (see Figures 19 to 25 ).

[0190]It should be noted that the magnetic flux changing portion according to the modified example as shown below is formed on the plate or the center pole portion of the yoke. In the description given below, only the differences from the plate 7 and the central pole portion 11 are described. Plates or center pole portions similar to those of the speaker device 1 described above are denoted by the same reference numerals, and descriptions thereof are omitted.

[0191]

[0192] The yoke 9A is arranged in such a manner that the front end of the center pole portion 11A protrudes forward from the plate 7 . According to the first modified example, the front end of the center magnetic pole portion 11A is provided as the magnetic flux changing portion 12A (see Figure 19...

example 3

[0210] Next, a modified example of the setting state of the lead wire or other wiring with respect to the bobbin will be described (see Figures 26 to 30 ).

[0211] It should be noted that only lead wires or other wiring are described in the modified examples given below. A bobbin around which a voice coil to which a lead wire or other wiring is to be connected is wound is denoted by the same reference numeral, and a description thereof is omitted.

[0212]

[0213] In the first modified example, two lead wires 17 are connected to the bobbin 14 while being arranged symmetrically with respect to the central axis P of the bobbin 14, and the lead wires 17 are arranged in a curved form (see Figure 26 ). It should be noted that three or more lead wires 17 may be provided as long as they are arranged symmetrically with respect to the central axis P of the bobbin 14 .

[0214]

[0215] In the second modified example, two lead wires 17 and connection wires 20 are connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com