Micropore atomization method and device for applying same

A technology of microporous atomization and atomization sheet, which is applied in spraying devices, liquid spraying devices, etc., can solve the problems of inducing diseases, threatening health, and inconvenient use of atomizers, and achieves bacteria-free, simple operation, and device Ease of use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

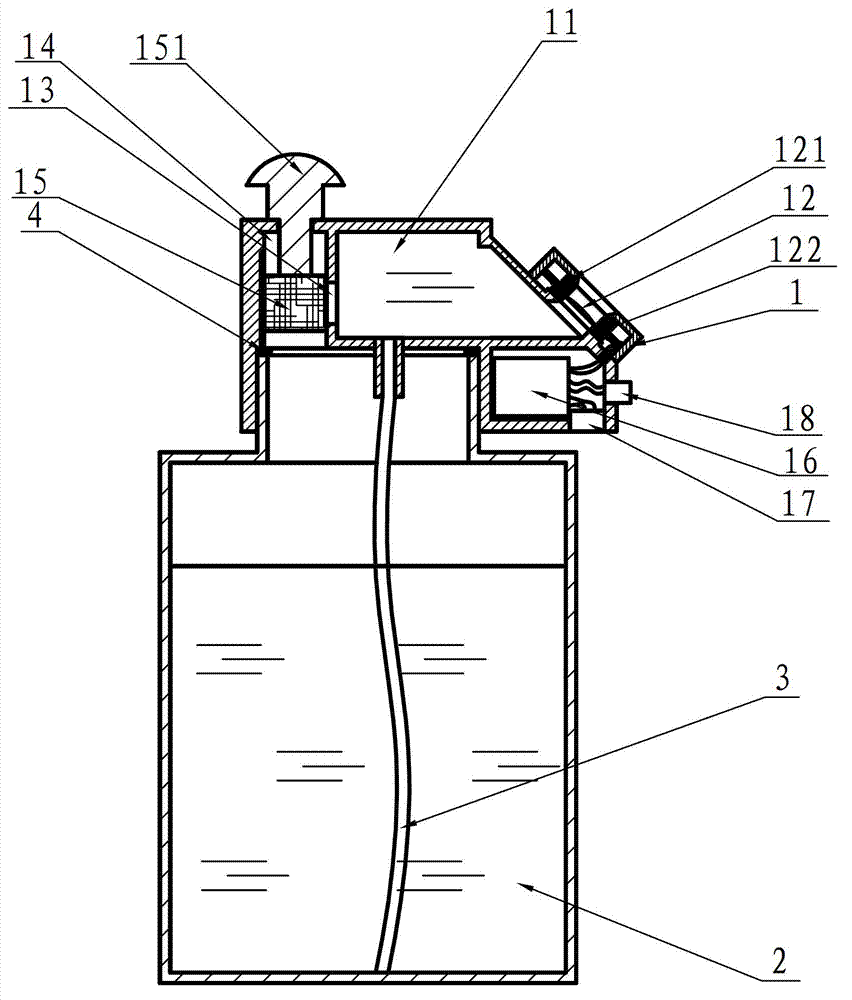

[0020] refer to figure 1 , the present invention is a kind of microporous atomization method, is characterized in that, comprises the following steps:

[0021] 1) Connect the water supply chamber 2 with the airtight water consumption chamber 11 through a conduit 3, and install the microporous atomization module 1 on the outer wall of the water consumption chamber 11;

[0022] 2) Turn on the driving module to make the microporous atomization module 1 work, and the microporous atomization module 1 consumes the liquid in the water consumption cavity 11 during the working process;

[0023] 3) During the water consumption process, a negative pressure is generated in the water supply cavity 2, and the liquid in the water supply cavity 2 passes through the conduit 3 to the water consumption cavity 11 under the action of the negative pressure.

[0024] A microporous atomization device, comprising a water supply cavity 2 and a closed water consumption cavity 11, connected with the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com