Parallelogram cross-section whole node rod piece lineation drilling technique

A technology of parallelogram and integral joints, which is applied in the field of scribing and drilling technology for rods with integral joints of parallelogram cross-section, and achieves the effects of strong operability, high work efficiency and high scribing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

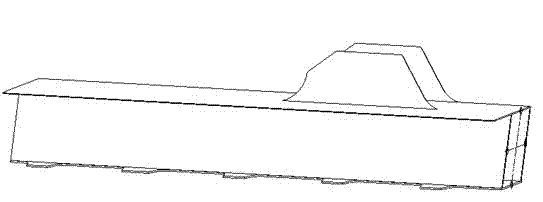

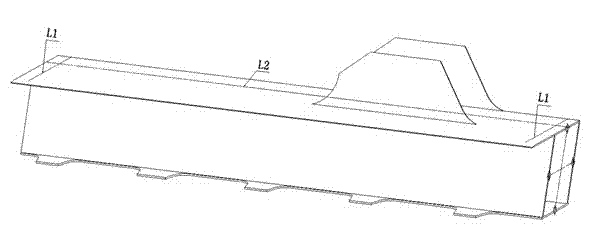

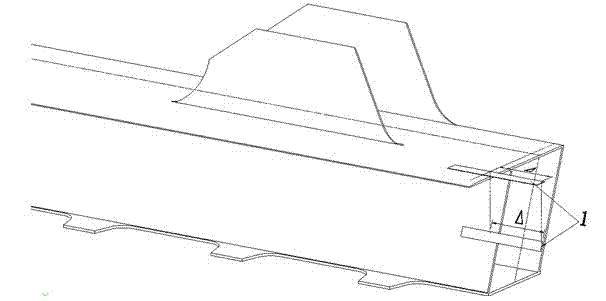

[0036] Such as Figure 1~Figure 13 As shown, the top plate of the bottom chord member of the integral node protrudes from the inner gusset plate, so that the plane of the inner gusset is divided into two parts, and the web system line of the inner gusset plate is accurately drawn by using the auxiliary point, and the hole group of the web member of the inner gusset plate is drilled to ensure that The accuracy of the relative dimensions of the web hole groups of the inner and outer gusset plates with front and rear misalignment features, including the scribing step of the inner web of the integral node member with a parallelogram cross-section,

[0037] The inner and outer flank system lines of the top chord members,

[0038] 1) After the welding of the rod group is completed, the flame is calibrated, and after passing the pass, it flows into the marking process, and white paint is painted on the marking area;

[0039] 2) After the marking bar is hoisted into the marking plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com