Overloaded manipulator of ten-shaft double-gantry

A double gantry and manipulator technology, applied in manipulators, program-controlled manipulators, collets, etc., can solve the problems of lack of production capacity and equipment for large-scale heavy-duty machinery, difficulty in processing materials with particularly large sizes, and small processing inch-length range, etc., to achieve The overall structure is firm and stable, with long service life and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

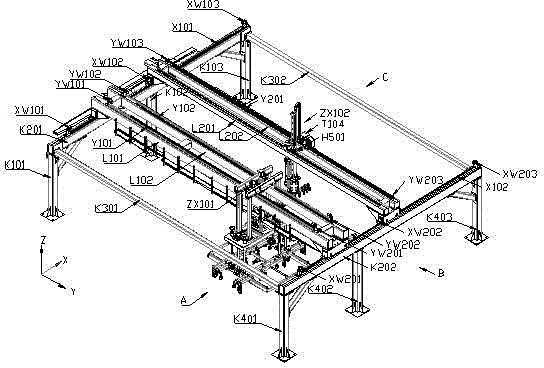

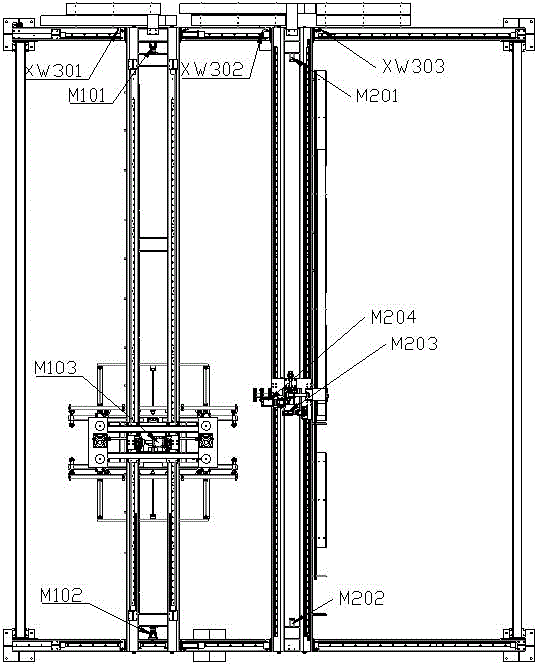

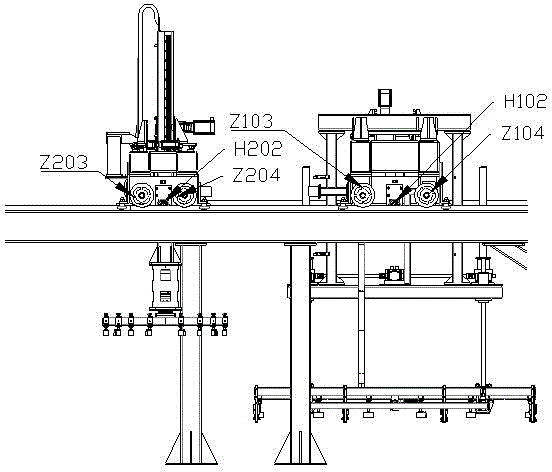

[0012] combine figure 1 and figure 2 , the heavy-duty manipulator of the ten-axis double-gantry structure of the present invention includes a frame, a first gantry and a second gantry, and the frame is composed of supporting legs, brackets K201, K301, K202, K302, racks and limiting components. The first The second, third, and fourth brackets K201, K301, K202, and K302 are connected end to end to form a four-sided frame. The first and third brackets K201 and K202 are parallel, and the second and fourth brackets K301 and K302 are parallel. The supporting legs are connected and support the four-sided frame. The first rack X101 in the X-axis direction and the first and second mechanical limit devices XW101 and XW103 are installed on the bracket K201, and the first and second mechanical limit devices XW101 and XW103 are located at both ends of the first rack X101; The second rack X102 in the X-axis direction and the third and fourth mechanical limiting components XW201 and XW203 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com