Driving force transmission apparatus

一种传递装置、驱动力的技术,应用在动力装置、气压力动力装置、通用动力装置的多个不同原动机的布置等方向,能够解决主离合器离合器动作响应性降低、燃料消耗率恶劣、无法获得离合器动作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

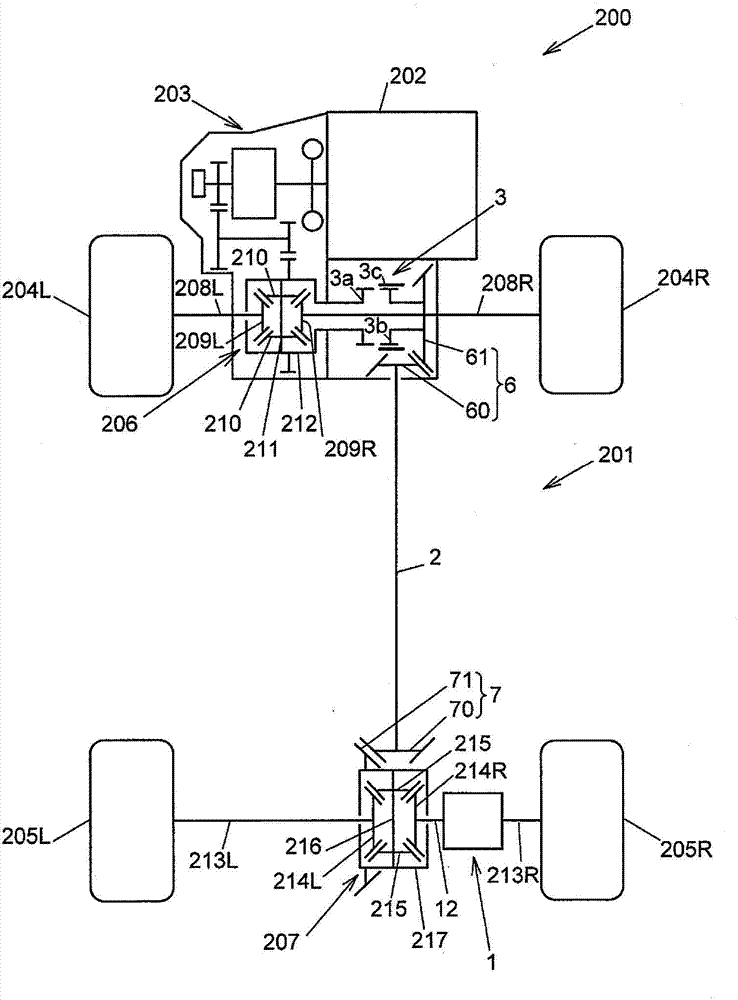

[0036] figure 1 Indicates the outline of a four-wheel drive vehicle. The four-wheel drive vehicle 200 includes a driving force transmission system 201 , an engine 202 , a transmission 203 , front wheels 204L and 204R as main drive wheels, and rear wheels 205L and 205R as auxiliary drive wheels.

[0037] The driving force transmission system 201 is arranged along the driving force transmission path from the transmission 203 side to the rear wheels 205L, 205R side in the four-wheel drive vehicle 200 together with the front differential 206 and the rear differential 207, and is mounted on the four-wheel drive vehicle 200. The body of the car 200 (not shown).

[0038] Moreover, the driving force transmission system 201 has: the driving force transmission device 1, the propeller shaft 2 and the driving force interruption device 3, and is configured to be able to switch the four-wheel drive state of the four-wheel drive vehicle 200 to the two-wheel drive state, or to The two-wheel...

no. 2 approach

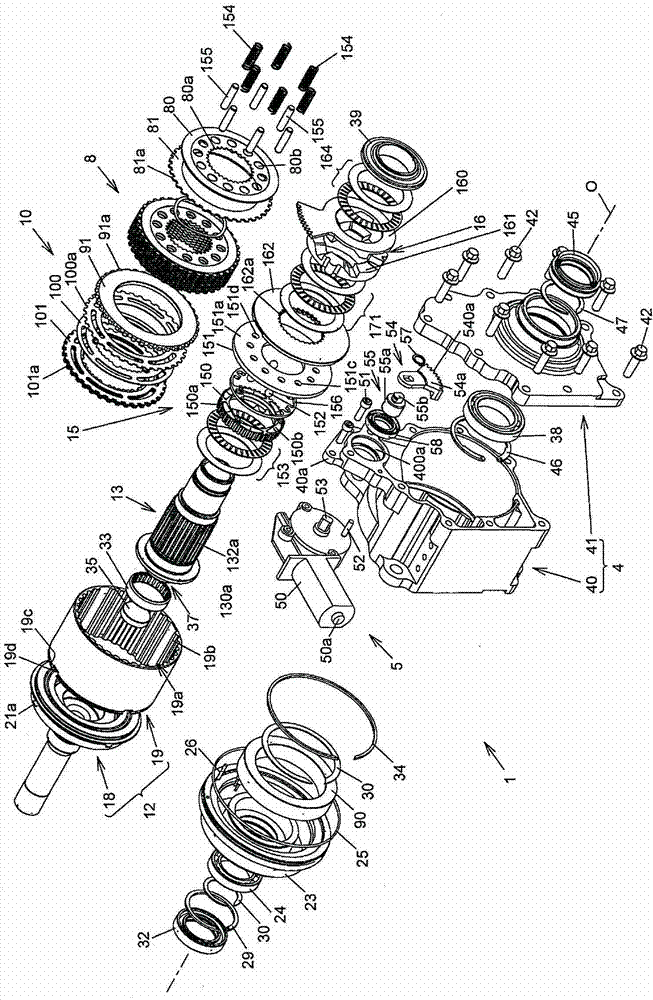

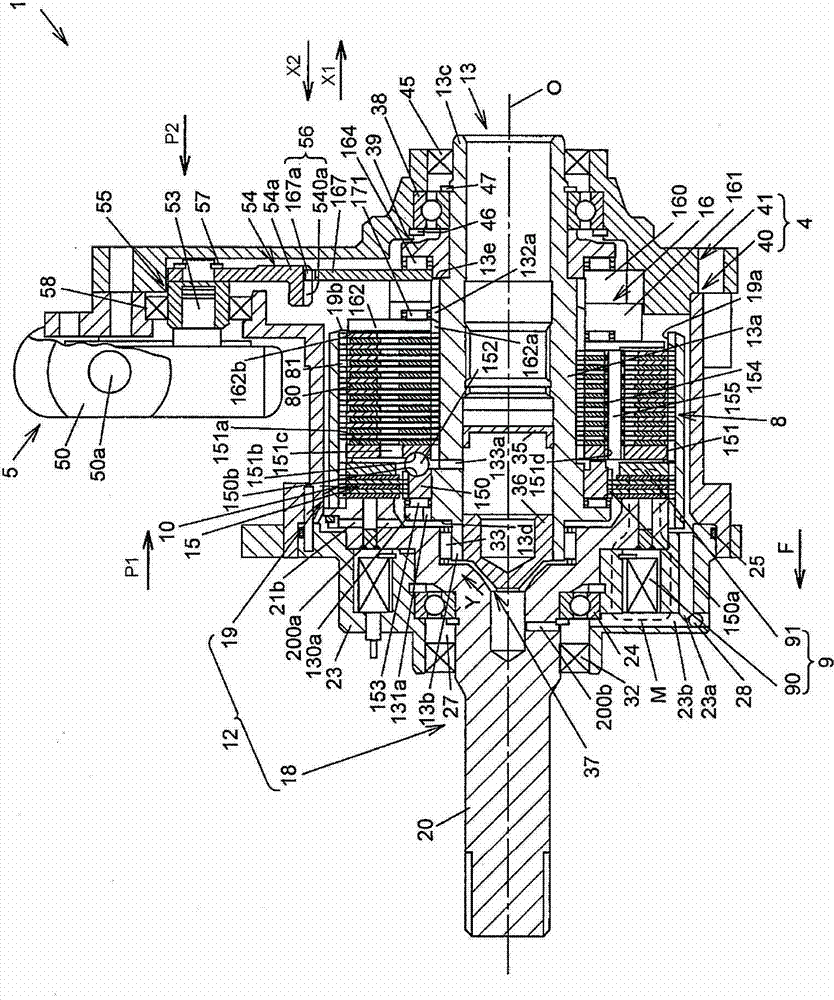

[0142] Next, combine Figure 9 ~ Figure 14A as well as Figure 14B A driving force transmission device according to a second embodiment of the present invention will be described. Figure 9 as well as Figure 10 Indicates the entire driving force transmission device. Figure 11 Indicates the rear case. Figure 12 Indicates the first element in the rear housing. Figure 13 Indicates the second element in the rear housing. Figure 14A as well as Figure 14B Indicates the third element in the rear housing. exist Figure 9 ~ Figure 1 4 and Figure 14B In the pair with figure 2 as well as image 3 Components with the same or equivalent functions are denoted by the same symbols, and detailed descriptions are omitted.

[0143] Such as Figure 9 as well as Figure 10 As shown, the driving force transmission device 190 according to the second embodiment of the present invention and the driving force transmission device shown in the first embodiment in which the open type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com