Heat radiation system for LED (light emitting diode) illumination

A technology of LED lighting and cooling system, applied in lighting and heating equipment, lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of poor cooling effect of LED lighting cooling system, avoid hard contact and ensure normal operation The effect of temperature on the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

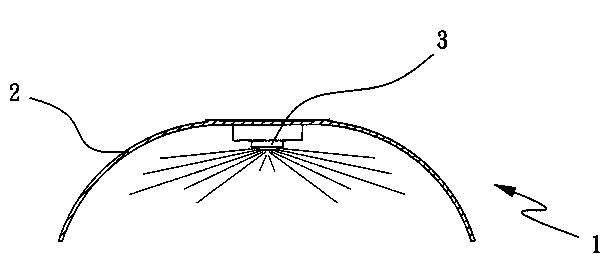

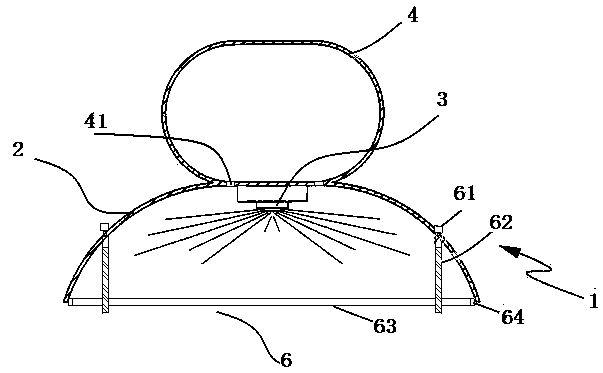

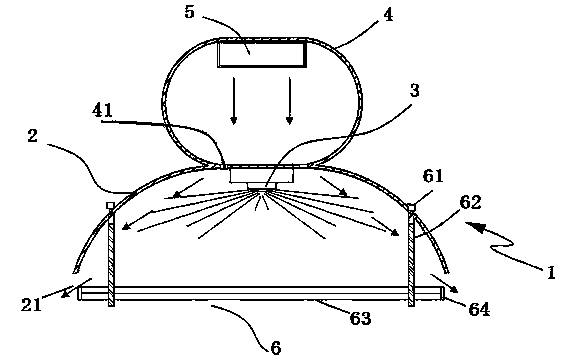

[0030] Combine below Figure 2 to Figure 8 , the present invention is further described:

[0031] Such as figure 2 To such as Figure 8 As shown, a LED lighting cooling system includes a lighting unit, a cooling unit, and a control unit. The lighting unit includes an LED fluorescent lamp 1 and a concentrating plate adjustment device 6. The cooling unit includes a temperature sensor and a cooling micro-fan 5. The temperature sensor collects on the circuit board The temperature is sent to the control unit for processing. The control unit controls the number of light-emitting diodes according to the temperature value collected by the temperature sensor and controls the opening of the heat dissipation micro-fan 5 and the condenser plate adjustment device 6. The condenser plate adjustment device 6 drives the condenser plate 63 to Move down and make the condensing plate 63 and the arc-shaped reflector 2 form a heat dissipation channel, and the heat dissipation micro fan 5 blows h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com