A disc-shaped asynchronous magnetic coupling and speed regulation method

A magnetic coupling and asynchronous technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of reduced assembly difficulty, high assembly difficulty, and reduced neutral requirements, so as to reduce friction and wear, Improved transmission efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

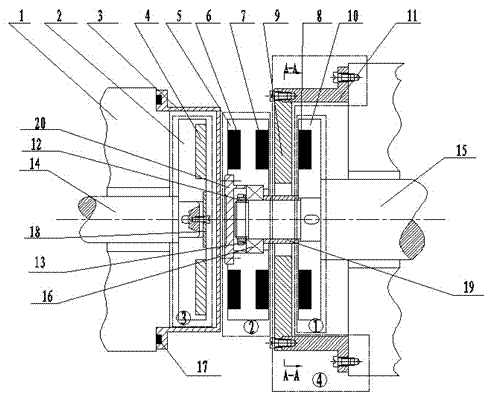

[0018] Combine below figure 1 The implementation of the present invention is described in detail, the general structure of the present invention is as follows figure 1 As shown, the device includes: driving disk assembly ①, intermediate disk assembly ②, driven disk assembly ③, magnetic adjustment device ④ and spacer 3; driving disk assembly ① consists of driving disk base 10, first permanent magnet 8, the intermediate disk assembly ② is composed of the intermediate disk base 5, the third permanent magnet 6, and the second permanent magnet 7, and the driven disk assembly ③ is composed of the driven disk base 2, the guide bar 4, and the conductor end ring 24. Magnetic adjustment device ④ is composed of magnetic adjustment pole piece 9 and fixed sleeve 11. It is characterized by: driven disk assembly ③, spacer sleeve 3, intermediate disk assembly ②, magnetic adjustment device ④ and driving disk assembly ① from left to The right is arranged axially along the driven shaft or the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com