Actuating drive, exhaust gas recirculating valve, turbocharger

A technology of exhaust gas recirculation and exhaust gas turbine, which is applied in the fields of exhaust gas turbocharger and exhaust gas recirculation valve, can solve problems such as increased wear and tear, and achieve the effect of simplifying support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

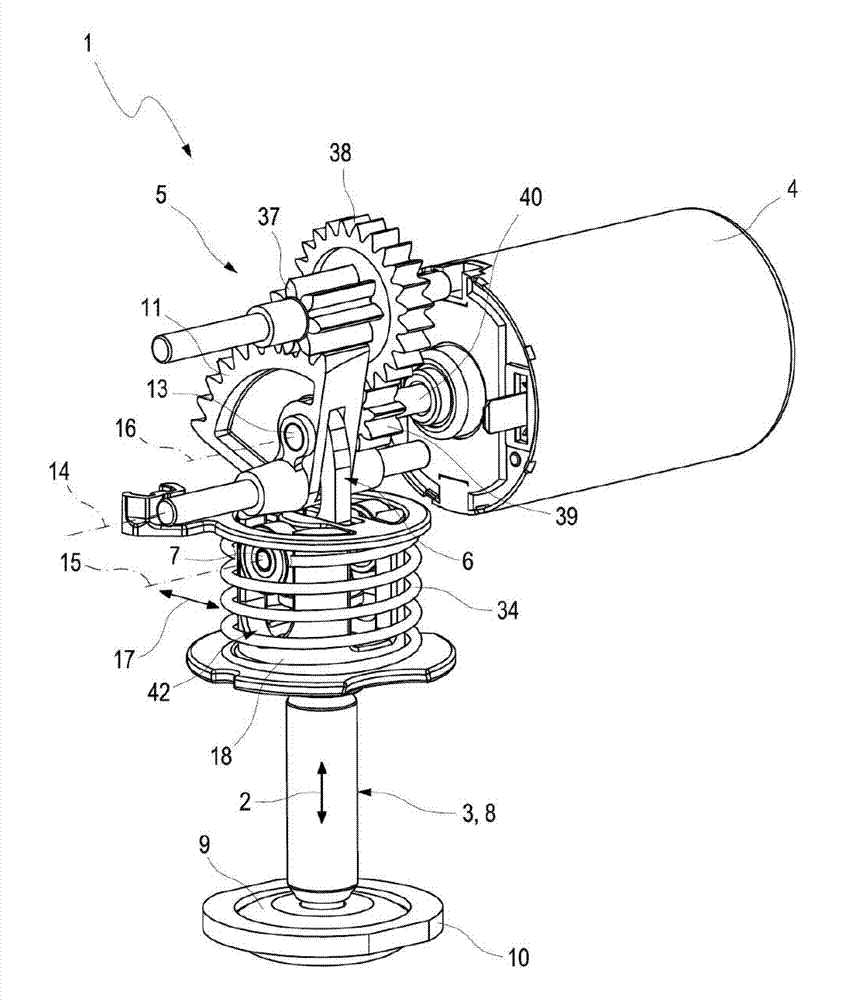

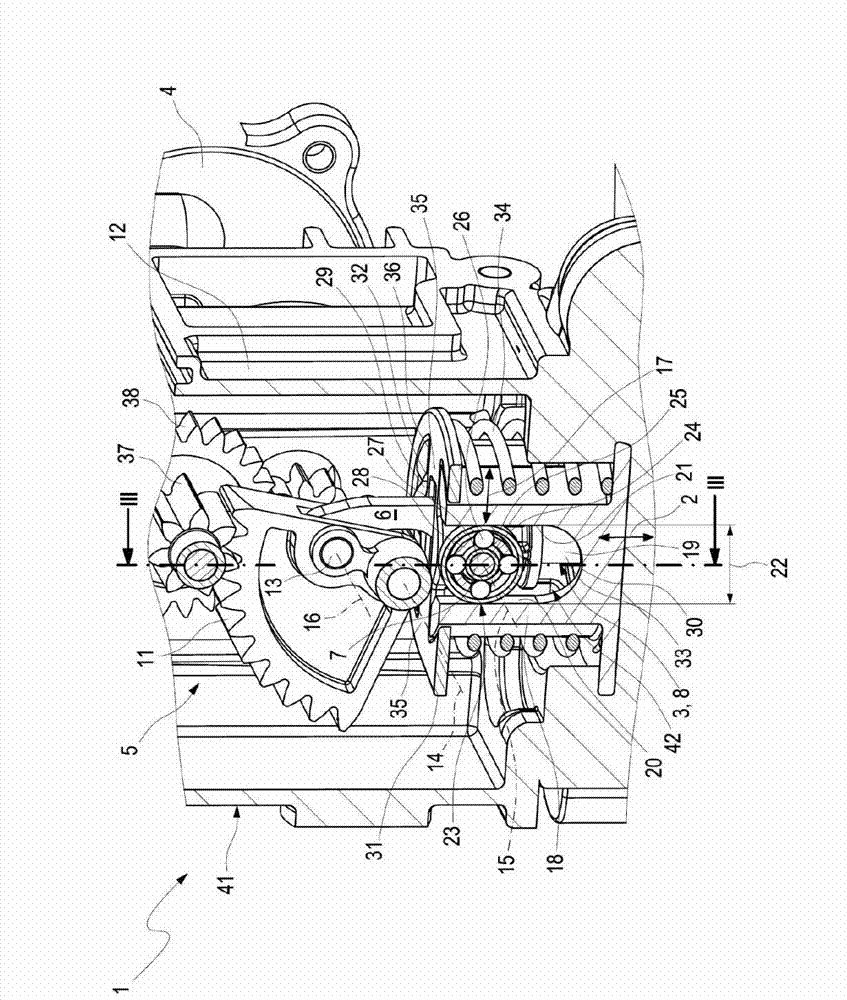

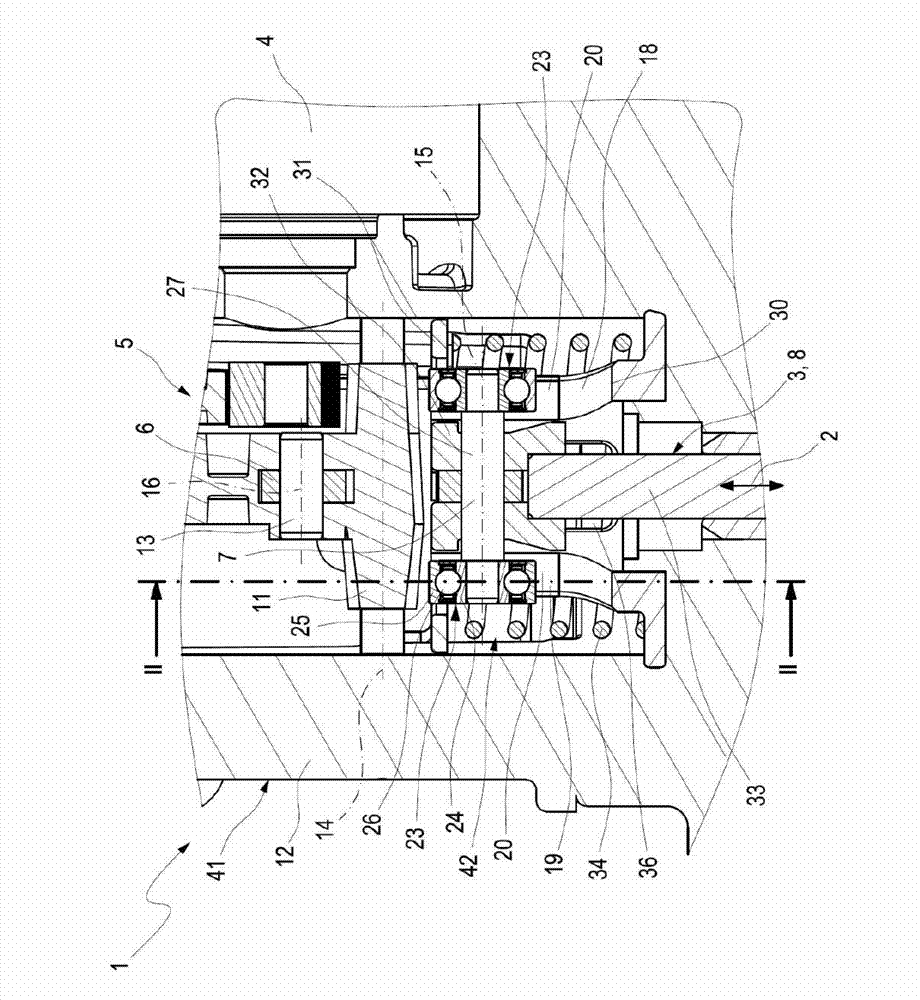

[0036] according to Figure 1~Figure 6 , the actuating drive 1 includes an actuator 4 for generating a driving force, a force transmission device 5 and a toggle lever 6 , and the actuating element 3 , which can be adjusted bidirectionally according to the double arrow 2 , can be driven by means of the actuating drive 1 . The actuator 4 is, for example, an electric motor. The force transmission device 5 is in the example a gear train. The toggle lever 6 is connected in an articulated manner to the actuation element 3 via a first toggle lever joint 7 . exist Figure 1~Figure 3 In the embodiment shown, the actuating element 3 can be, for example, a valve element 8 which has a valve body 9 and which is adjusted relative to a valve seat 10 . The actuating drive 1 can be used, for example, in an exhaust gas recirculation valve of an exhaust gas recirculation device of an internal combustion engine, in particular a motor vehicle. Then, in order to set the exhaust gas recirculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com