Transistor ladder network for driving a light emitting diode series string

A technology of light-emitting diodes and transistors, which is applied in the field of transistor ladder networks used to drive series strings of light-emitting diodes, and can solve problems such as harmonic distortion of LED strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the LED drive circuit allow driving multiple LEDs in series in AC line applications with minimal harmonic distortion in the drive current and near unity power factor. The circuit also allows direct dimming as well as color changes via dimmer circuits (eg, conventional TRIAC dimmers). In addition, the circuit is protected against line voltage surges and is relatively insensitive to brown-out operation.

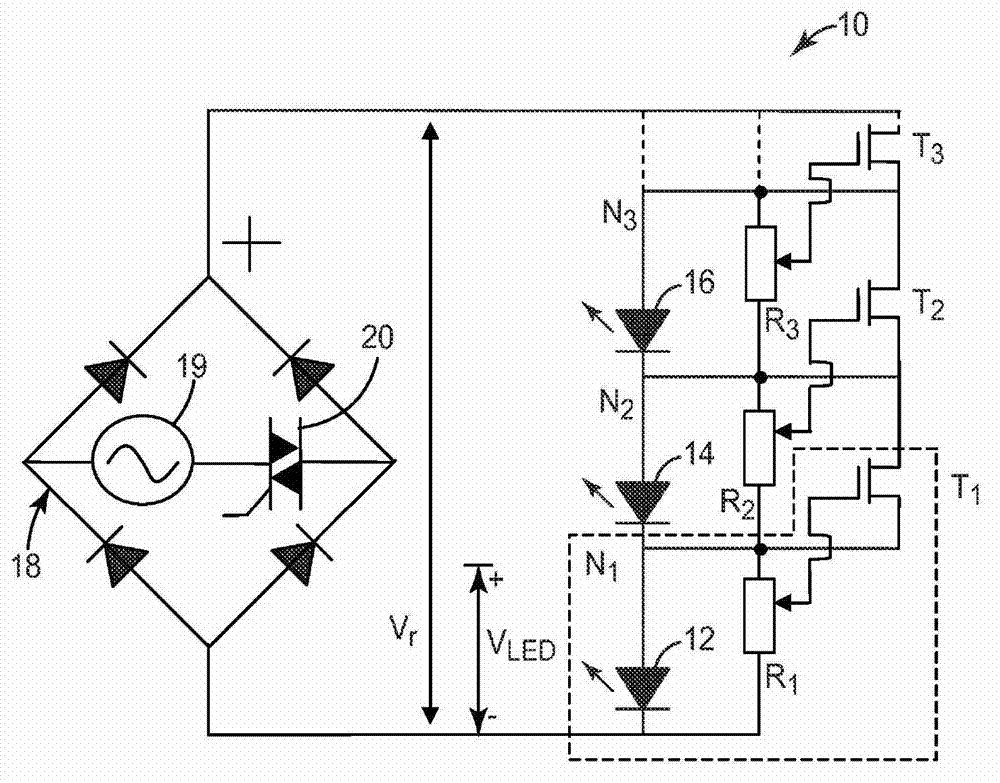

[0013] figure 1 is a schematic diagram of a FET circuit 10 for driving a series string of LEDs. The circuit 10 comprises a series of three (m=3) segments N connected in series 1 , N 2 and N 3 . Each segment controls N m LED junction. The first section includes N 1 LED junction 12 (shown as a diode), resistor R 1 and transistor T 1 . The second section includes N 2 LED junction 14 (shown as a diode), resistor R 2 and transistor T 2 . The third section includes N 3 LED junction 16 (shown as a diode), resistor R 3 and transistor T 3 . In e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com