Resin sand winnowing machine

A wind separation machine and resin sand technology, applied in the cleaning/processing machinery of casting materials, solid separation, separating solids from solids with air flow, etc., can solve the problems of small wind separation power, poor selection effect, and waste and other problems, to achieve the effect of solving unclear separation, good selection effect, and strong ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

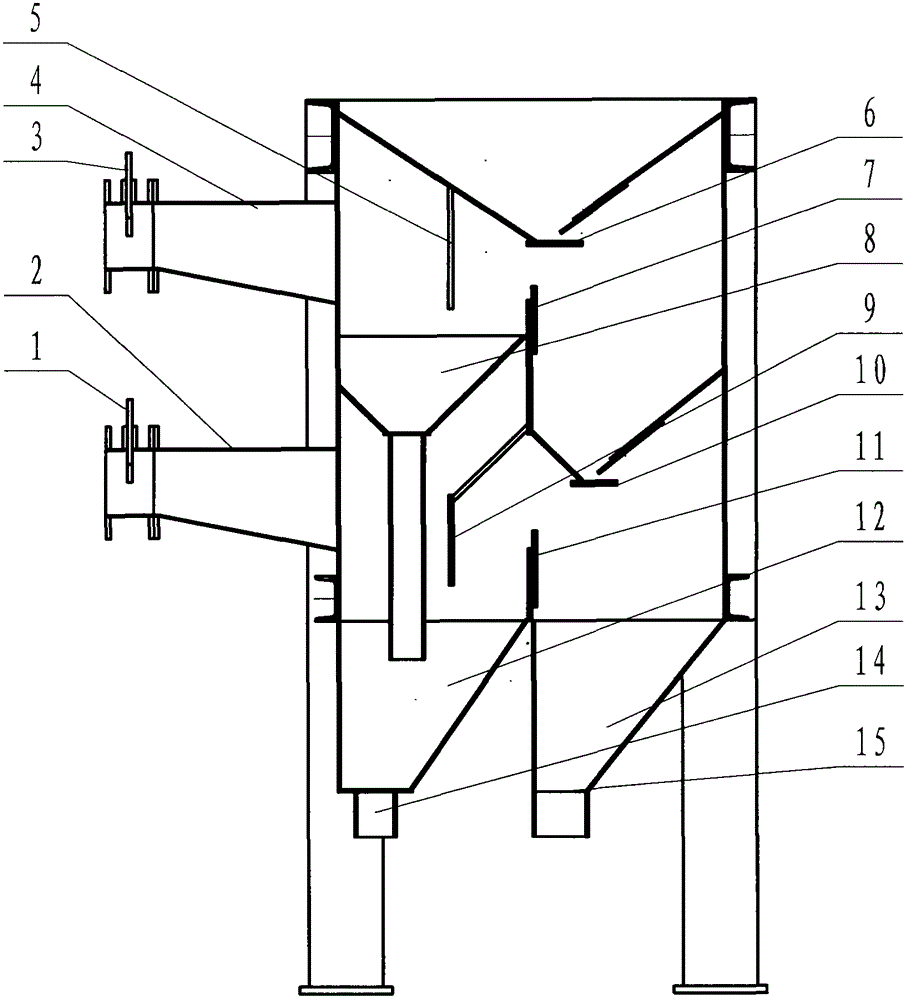

[0016] Such as figure 1 As shown, a resin sand winnowing machine, it includes valve 1, secondary ventilation pipe 2, valve 3, primary ventilation pipe 4, primary blocking plate 5, primary drop plate 6, primary adjusting plate 7, primary ash collecting hopper 8. Secondary blocking plate 9, secondary drop plate 10, secondary regulating plate 11, secondary ash collecting bucket 12, sand collecting bucket 13, ash outlet 14 and sand outlet 15. Wherein the primary ventilation pipe 4 is installed on the left side of the resin sand winnowing machine, and the secondary ventilation pipe 2 is installed directly below the primary ventilation pipe 4; position; the secondary ash collection bucket 12 is set under the primary ash collection bucket 8, and the bottom of the secondary ash collection bucket 12 is provided with an ash outlet 14; the secondary blocking plate 9 is located above the secondary ash collection bucket 12 and faces the second ash collection bucket Secondary ventilation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com