High-efficiency continuous washing separation tower and dephenolized fraction separation method

A separation tower and high-efficiency technology, applied in the field of metallurgical coking, can solve the problems of unclear interface separation between sodium phenolate solution and dephenolized fraction, and achieve the effects of easy control, stable operation and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

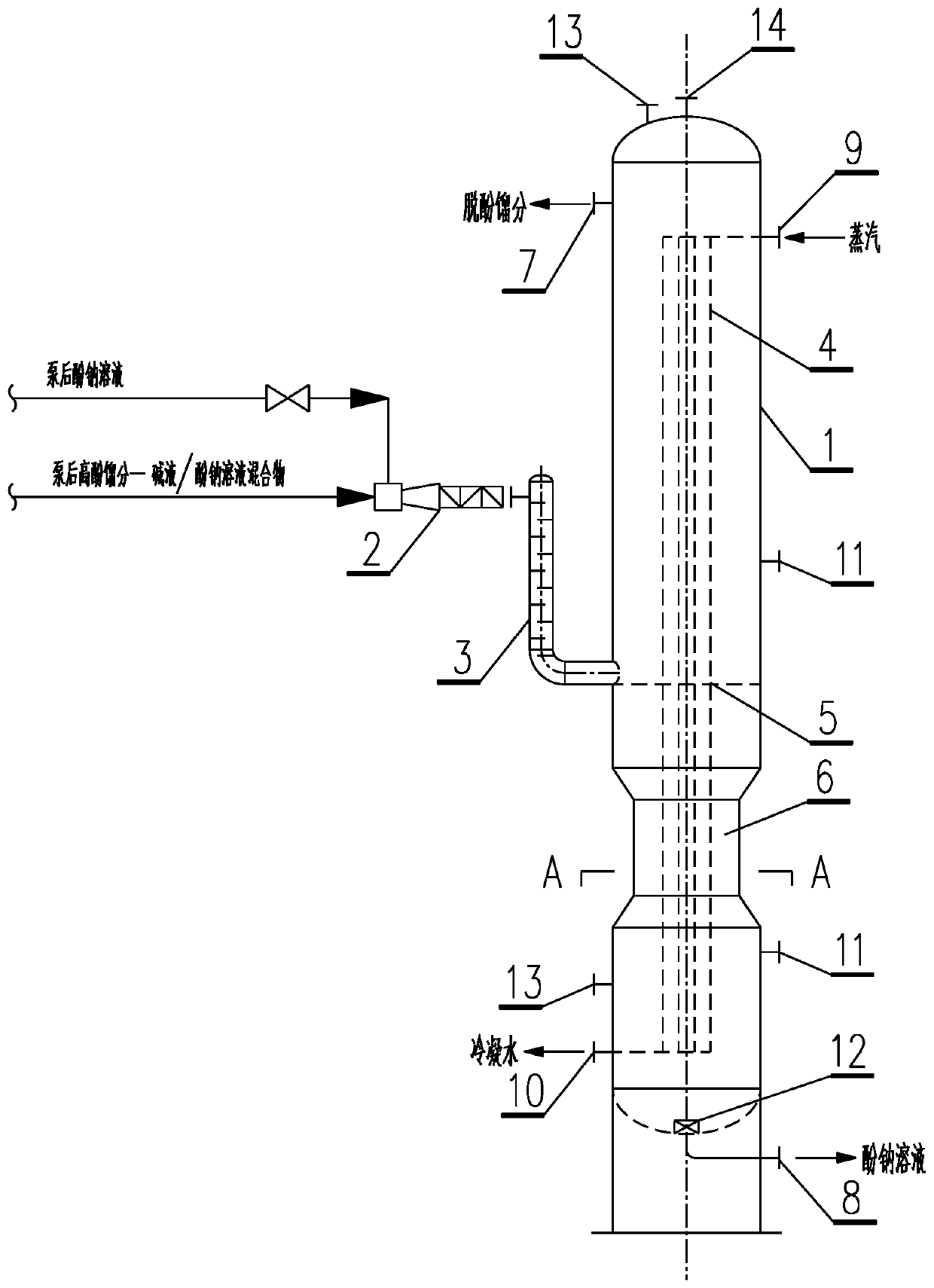

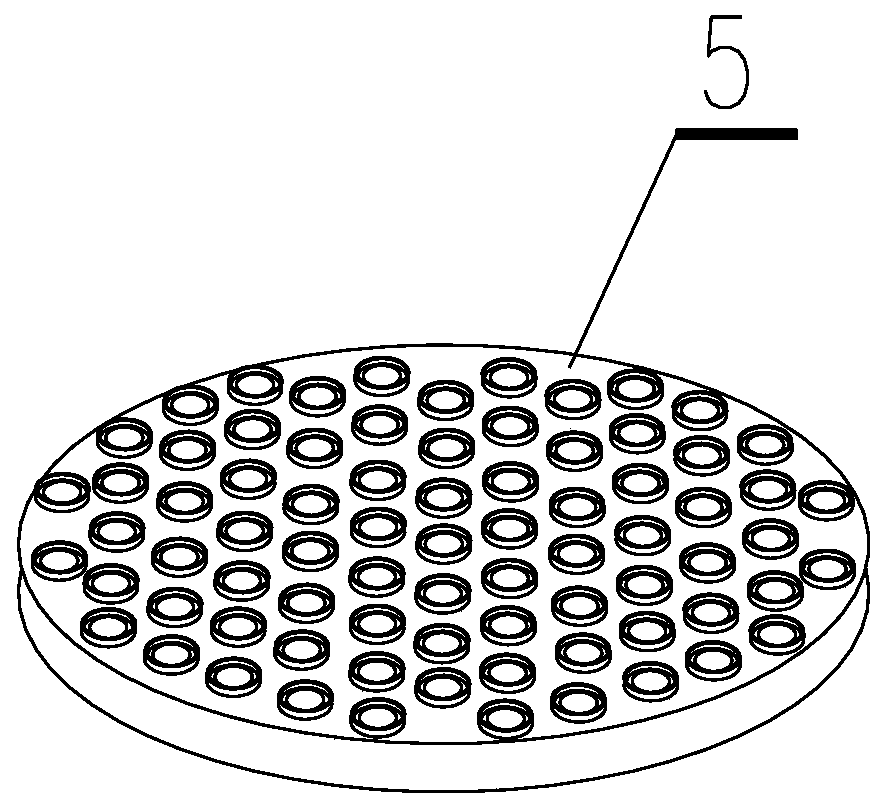

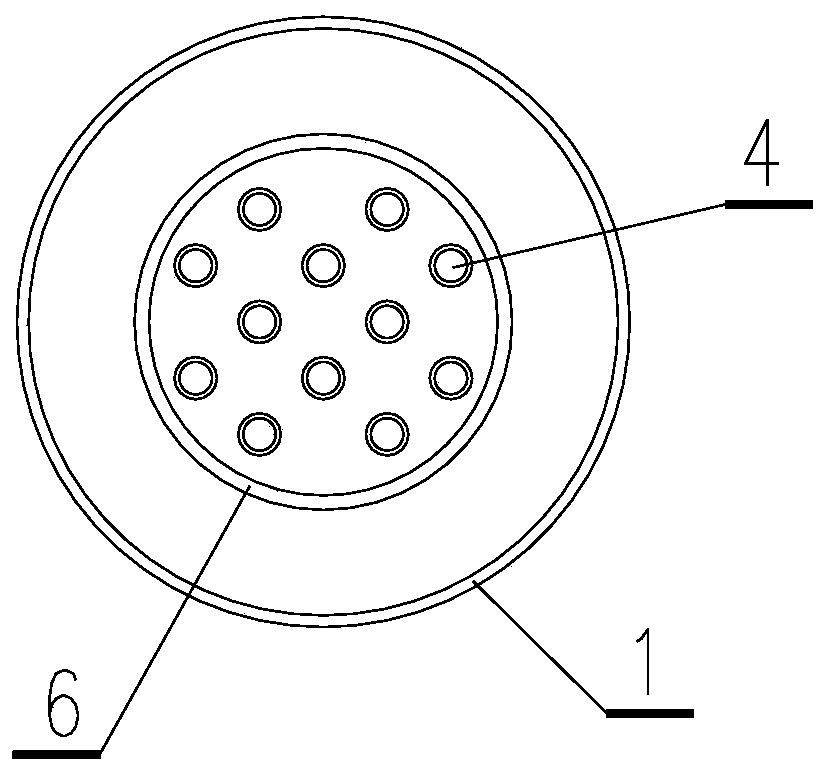

[0037] like figure 1 As shown, a high-efficiency continuous washing separation tower of the present invention includes a tower body 1, an L-shaped feed buffer 3, a pipeline mixer 2 and a heater 4; the bottom of the tower body 1 is provided with a necking section 6 , the necking section 6 divides the tower body 1 into an upper tower body and a lower tower body; the top of the upper tower body is provided with a vent 14, the upper part is provided with a dephenolized fraction outlet 7 and a steam inlet 9, and the lower part of the upper tower body is provided with a raw material mixture inlet , the raw material mixture inlet is connected to the material outlet of the pipeline mixer 2 through the L-shaped feed buffer 3, and the material inlet of the pipeline mixer 2 is connected to the high phenol fraction-alkali / sodium phenate solution mixture deliv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com