Manufacturing method for pot with mouth portion provided with embossing structure

A manufacturing method and pot technology are applied to pots with an embossed structure at the mouth and its manufacturing field, which can solve the problems of unsuitable shape of the pot body, lack of three-dimensional effect, monotonous color, etc., and achieve the best industrial utilization value, Increase the desire to buy, increase the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

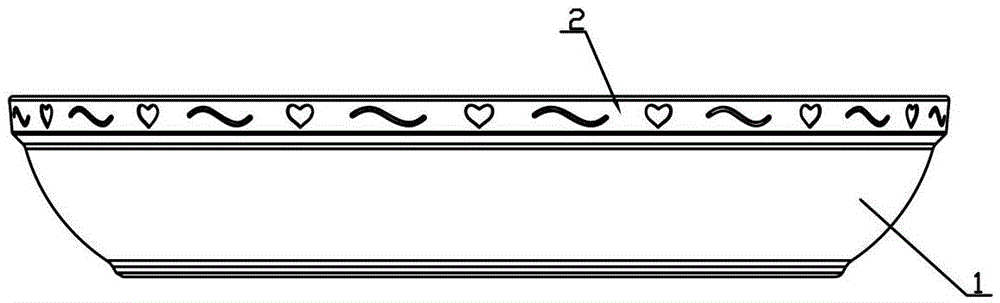

[0021] Such as figure 1 In the shown pot, the upper edge surface of the outer peripheral wall of the aluminum alloy pot body 1 forms a three-dimensional lace 2 with a concave pattern. Affect the cooking function and strength of the pot. The patterns on the three-dimensional lace 2 are evenly distributed. The upper edge surface of the peripheral wall of the pot body protrudes from the peripheral wall of the pot body.

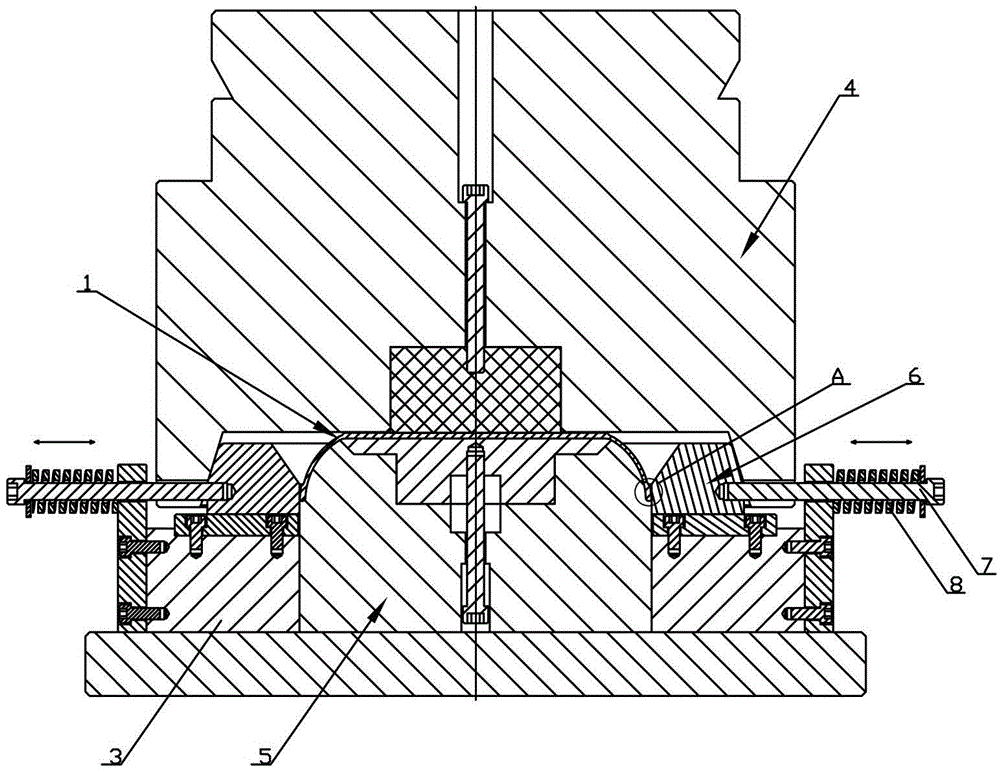

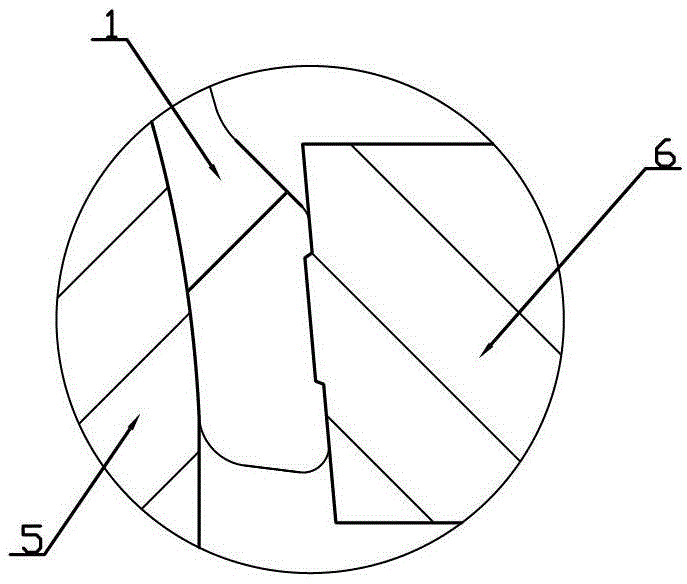

[0022] Such as Figure 2-3 The mold shown is that the iron or aluminum alloy base material is processed into a pot body by stretching; The lower mold 5 above the upper mold and capable of moving up and down is composed of four extrusion sliders 6 located outside the lower mold that can move inward. The four extrusion sliders 6 are evenly distributed in the circumferential direction. When squeezing the mouth of the pot body, All the extrusion sliders surround the mouth of the pot body, so that a circle of three-dimensional lace can be processed. The inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com