Railway vehicle car roof wind deflector

A rail vehicle and shroud technology, which is applied in the direction of railway car body, railway car body parts, climate sustainability, etc., can solve the problems of easy formation of water accumulation, etc., and achieve easy installation, improved aesthetics, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

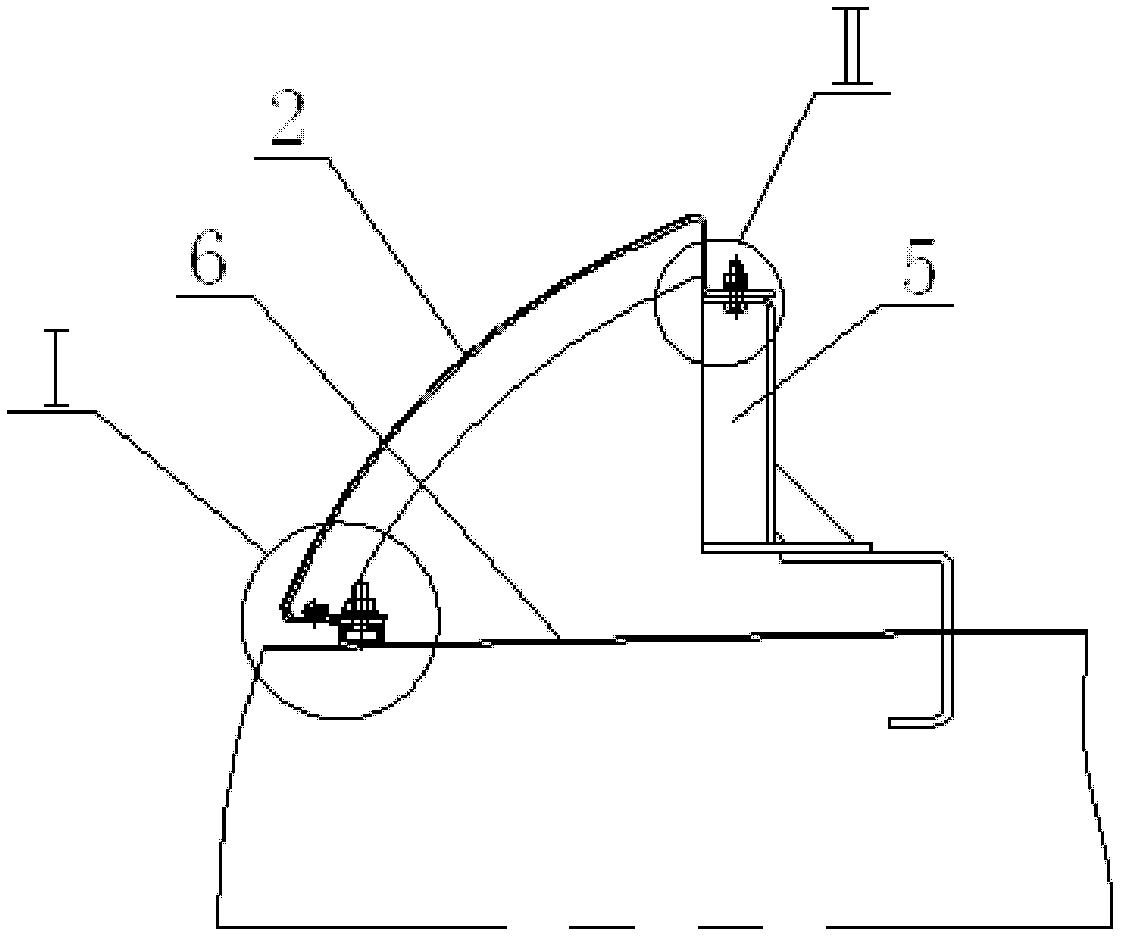

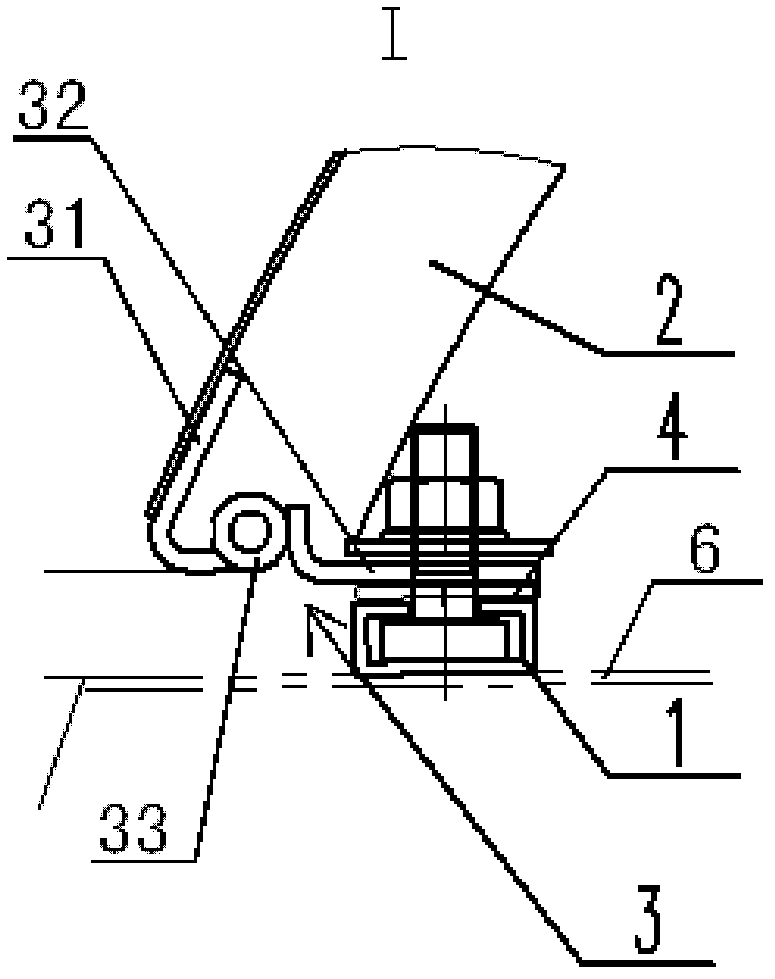

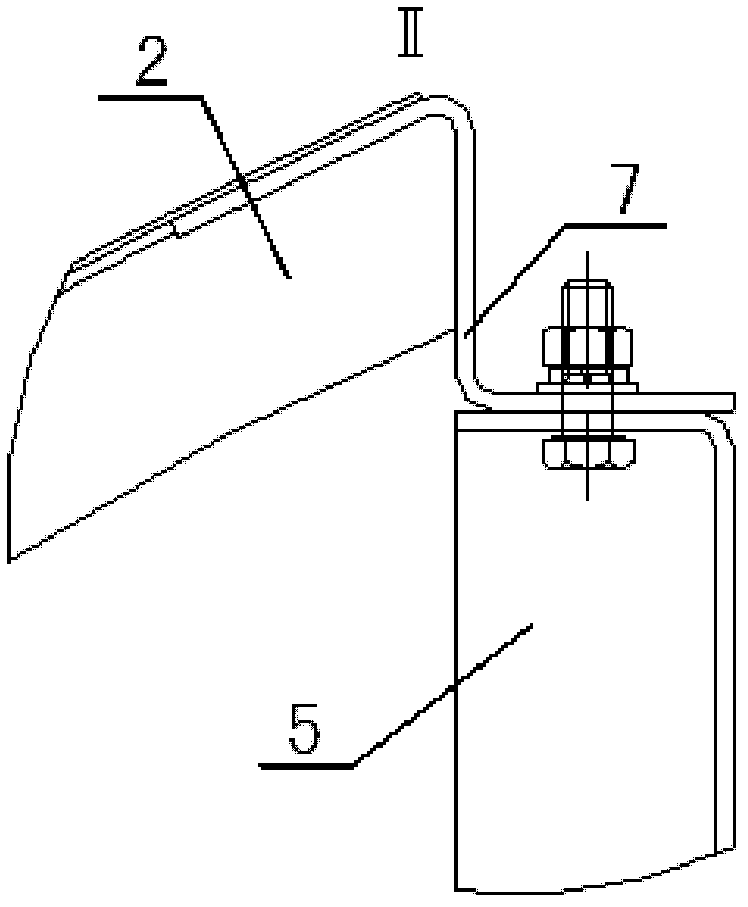

[0014] The rail vehicle roof deflector of the present embodiment, as figure 1 , figure 2 , image 3 As shown, it includes: an arc-shaped spoiler plate 2, a fixed frame 5 is welded on the inner side of the flat roof 6 of the car body, and a mounting seat 1 is welded on the outer side of the flat roof 6 of the car body, and the upper end surface of the mounting seat 1 has a longitudinal opening along the flat roof of the car body. Inverted T-shaped chute, the upper end of the arc-shaped wind deflector plate 2 is welded with a Z-shaped connecting plate 7, the upper end of the Z-shaped connecting plate 7 and the fixed frame 5 are connected by bolts, and the lower end of the arc-shaped wind deflector plate 2 is welded with The hinge 3 is fixed to the mounting base 1 by bolts, and an adjusting gasket 4 is arranged between the hinge 3 and the mounting base 1 . Such as figure 2 As shown, the hinge 3 includes a first part 31 welded to the inner wall of the arc-shaped spoiler panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com