Fluorosilicone rubber continuous-polymerization method

A technology of fluorosilicone rubber and polymerization method, which is applied in the field of continuous polymerization of fluorosilicone rubber, can solve the problems of large pressure loss and does not involve continuous polymerization of fluorosilicone rubber, so as to avoid large pressure loss, high production efficiency, and equipment structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

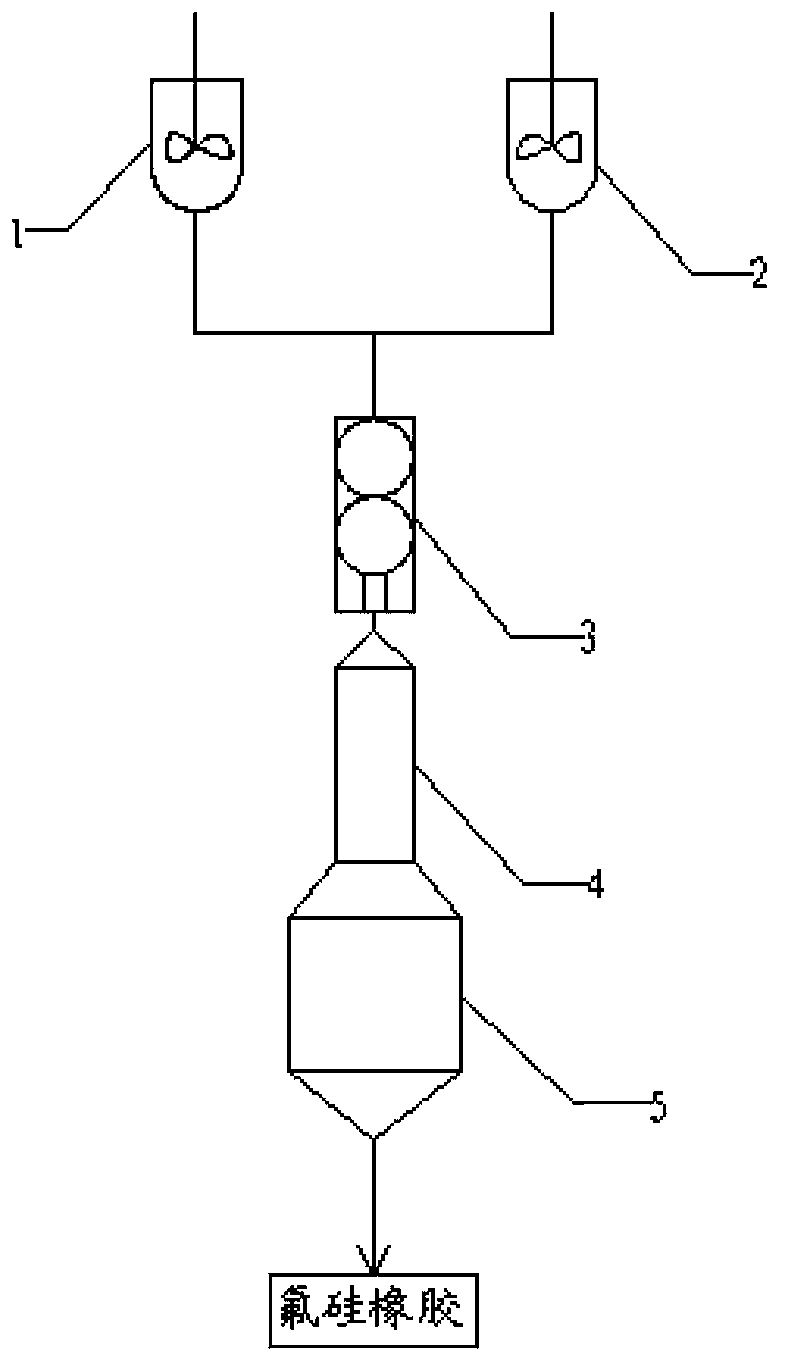

[0033] Such as figure 1 As shown, use a dehydration kettle A1 and a dehydration kettle B1 with a volume of 500 liters, a stirring feed port, a discharge port, an evacuation port and a sight glass, and first add trifluoropropylmethylcyclotrisiloxane to the dehydration kettle A1 300kg alkane, stirring, then add 1kg lithium silanolate catalyst, 0.1kg small molecular weight hydroxy fluorosilicone oil (viscosity is 60mPa S) and 1.5kg tetravinyltetramethylcyclotetrasiloxane in dehydration kettle A1, heat Raise the temperature to 60°C and dehydrate for 3 hours under the pressure of -0.95MPa. After the dehydration is completed, the material is transferred to the small-diameter JTSV static mixer 4 through the metering pump 3, and the conveying speed is controlled at 50kg / hour. When half of the material in the dehydration kettle A1 is transferred to the small-diameter JTSV static mixer 4 through the metering pump 3, add 300 kg of trifluoropropylmethylcyclotrisiloxane to the dehydration...

Embodiment 2

[0035] Repeat the steps described in embodiment 1, adjust the conveying speed of metering pump 3 and control at 100kg / hour, adjust the material residence time of JTSV type static mixer 4 at 0.5 hour, adjust the material residence time of JTX2 type static mixer 5 at 1 Hour. Fluorosilicone rubber with a molecular weight of 500,000-700,000 and a volatile content of 2-4% is obtained.

Embodiment 3

[0037] Repeat the steps described in Example 1, adjust the conveying speed of metering pump 3 to control at 34kg / hour, adjust the material residence time of JTSV type static mixer 4 at 1.5 hours, adjust the material residence time of JTX2 type static mixer 5 at 3 Hour. Fluorosilicone rubber with a molecular weight of 850,000 to 950,000 and a volatile content of 1.5 to 2.5% are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com