Preparation method of ABS plastic

A plastic and latex technology, applied in the field of plastic preparation, can solve the problems of slightly poor product appearance, inability to feed materials immediately, energy consumption, and high material consumption, and achieve the effects of improving product quality, reducing energy consumption, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

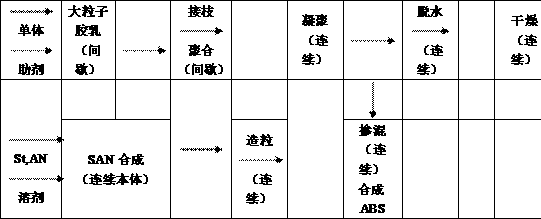

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, the present invention is described in further detail:

[0038] A kind of preparation method of ABS plastic provided by the present invention comprises the following steps:

[0039] l. Synthesize the small particle polybutadiene latex that reaches the required conversion rate by continuous method;

[0040] m. According to the proportion, continuously add the additional

[0041] Polymerizing agent, start to add stabilizer after 1.5 minutes, obtain the polybutadiene latex flow of large particle diameter;

[0042] n. Continuously add some styrene, acrylonitrile, mercaptan to the polybutadiene latex flow in proportion

[0043] After a certain period of time, stop adding styrene and acrylonitrile, and the latex stream containing the monomers is continuously flowed into the graft head kettle, and after staying in this kettle for 40 minutes, it flows into the second kettle;

[0044] o. Continuously drop the remaining emulsifier,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com