Method for replacing 10kV multi-layered overhead line pole towers with steel pipe poles in situ

A technology for overhead lines and steel pipe poles, which is applied in the field of replacing steel pipe poles for 10kV multi-layer overhead line towers, which can solve problems such as economic loss, aesthetic impact, and easy changes to the status quo of urban streets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

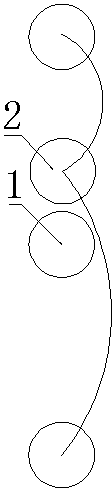

[0028] Such as figure 1 As shown, the steps of the method for replacing steel pipe poles in situ for the 10kV multi-layer overhead line tower are as follows:

[0029] 1. Erect the cement tower 2 in front of the old tower 1.

[0030] 2. Release the span between the front and rear towers of the old tower 1, so that the transmission line corresponding to the old tower 1 becomes longer. When releasing the span, the release length is the same as the length of the transmission line between the front and rear towers of the old tower 1 The sum is greater than or equal to the line distance between the old tower 1 front tower to the cement tower 2 to the old tower 1 rear tower.

[0031] 3. Move the transmission line on the old tower 1 to the cement tower 2.

[0032] 4. Remove the old pole tower 1, and dig a pole pit at the location of the old pole tower 1.

[0033] 5. Make a steel pipe pole foundation with a flange in the pole pit, and dry it for 7 days until the steel pipe pole foun...

Embodiment 2

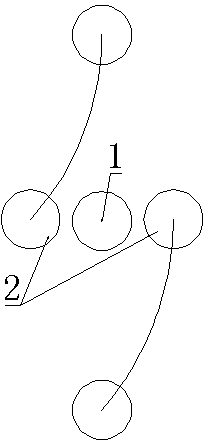

[0037] The old tower 1 is an expansion-resistant tower, and there are two cement towers 2, which are respectively located on the left and right sides of the old tower 1, and the others are the same as in the first embodiment.

Embodiment 3

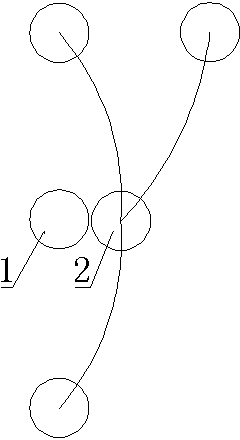

[0039] The old tower 1 is a tower with a single branch, and the cement tower 2 has one. When the branch is biased to the left, the cement tower 2 is located on the left side of the old tower 1. When the branch is biased to the right , the cement tower 2 is located on the right side of the old tower 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com