Installation method of accident oil discharge device of high-end converter transformer

A converter transformer and installation method technology, applied in the direction of transformer/inductor cooling, switchgear, electrical components, etc., can solve the problems of fire spread, damage to the converter valve, fire and explosion, etc., and achieve scientific and economical installation methods. Labor cost, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

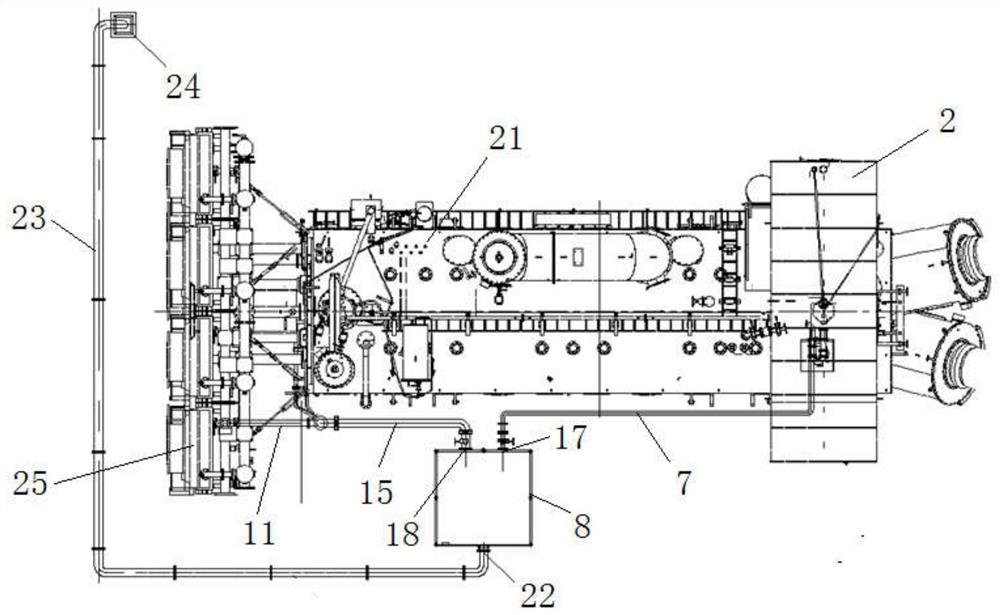

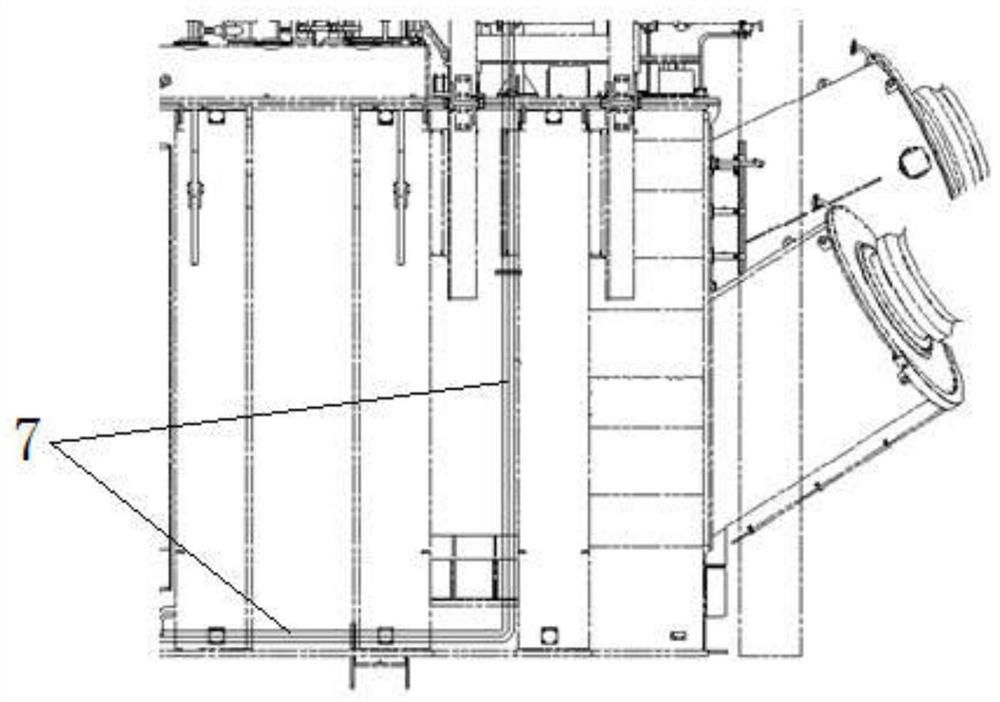

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A method for installing an emergency oil discharge device for a high-end converter transformer, comprising the following steps:

[0034] Step 1): Cut off the power of the converter transformer, and put it in the state of shutting down for maintenance, and add an oil storage pool to store the transformer oil discharged after the accident.

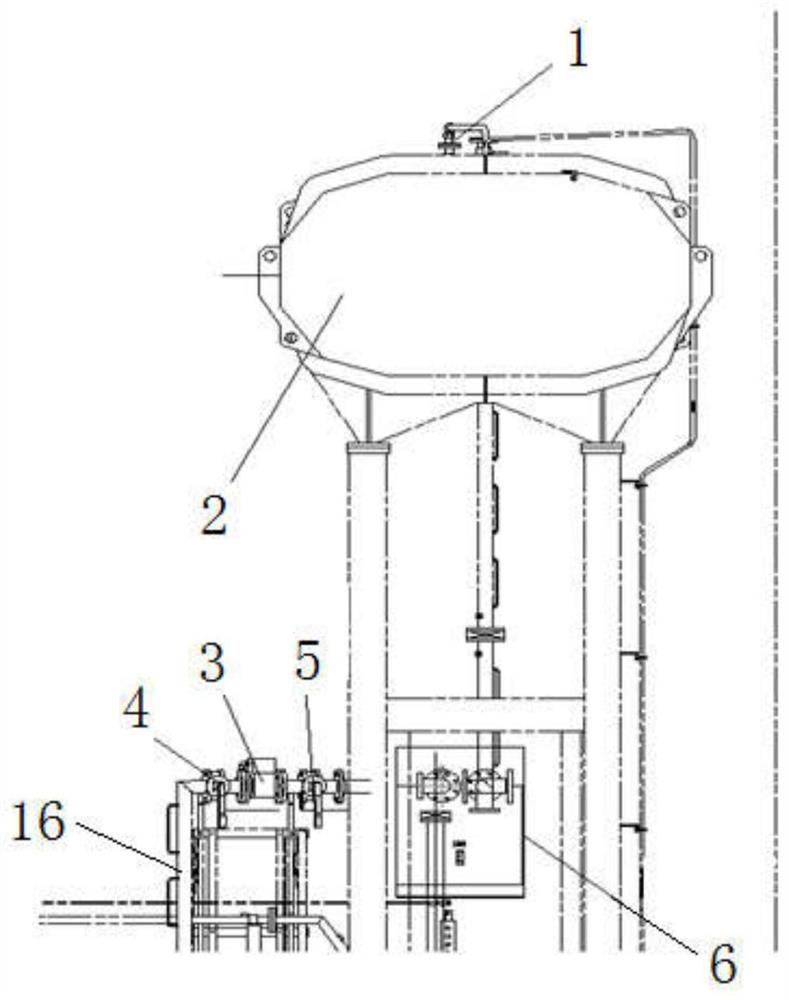

[0035] Step 2): Drain the transformer oil in the oil conservator 2 .

[0036] First of all, in the maintenance state, the valve a4 and the valve b5 at both ends of the gas relay 3 on the main gas connection pipe 16 of the converter transformer are closed first, and the gas relay 3 is removed.

[0037] Since the installed oil discharge device needs to be processed accordingly, the transformer oil in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com