Honing tool for honing blind bores

A honing and tool technology, applied in the field of honing blind drilling, can solve the problems of frequent disassembly of honing tools, and achieve the effect of improving the drilling geometry and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

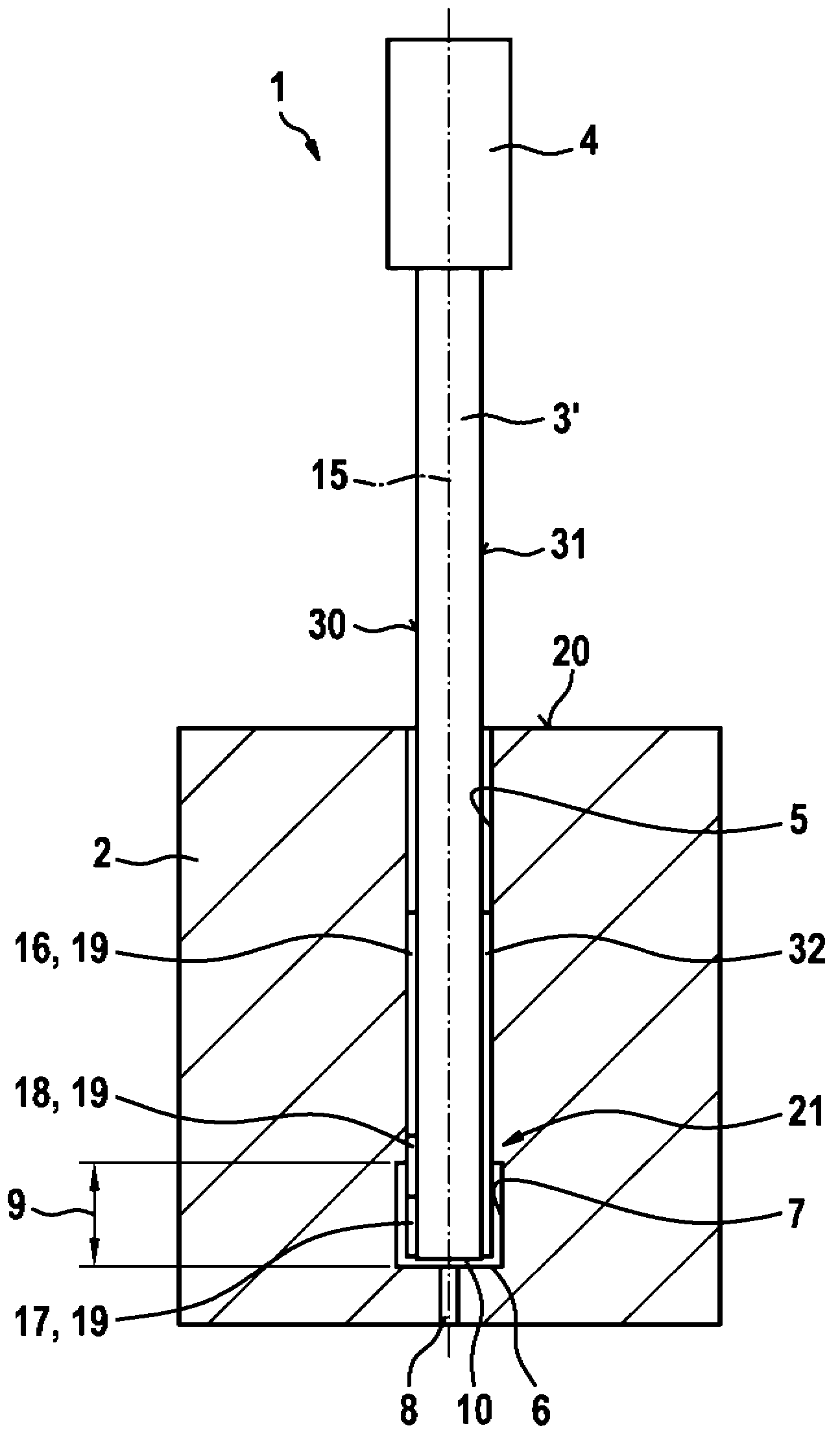

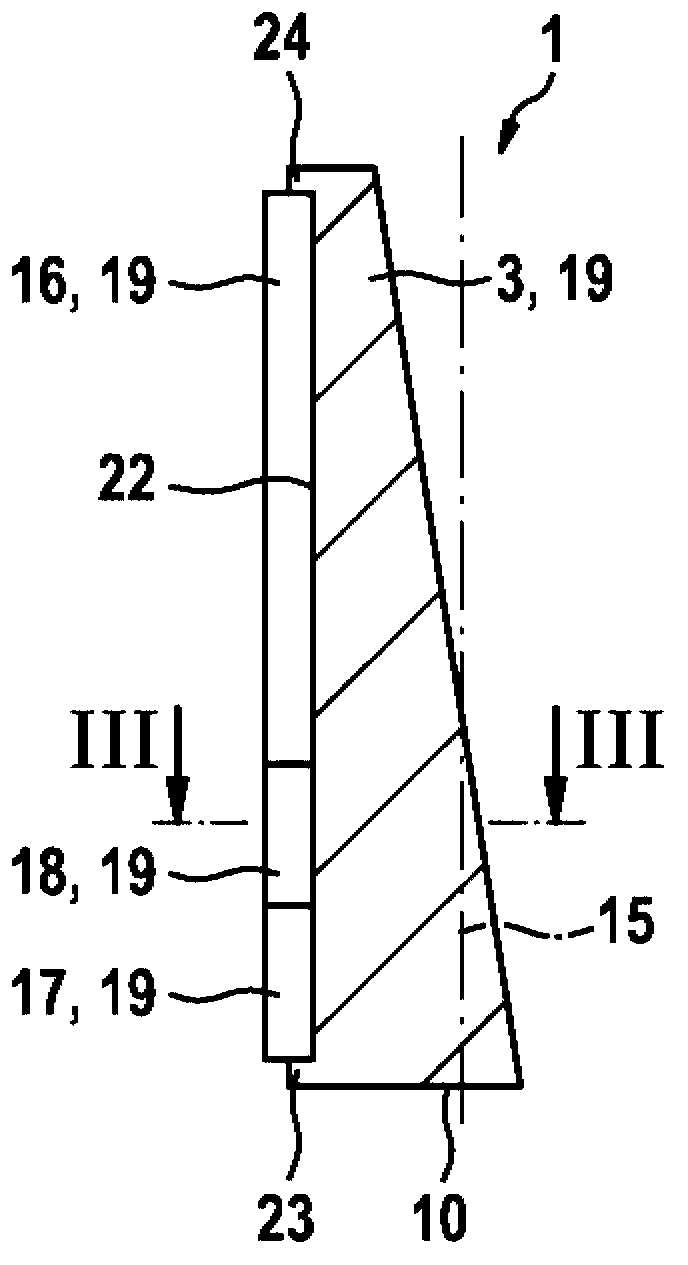

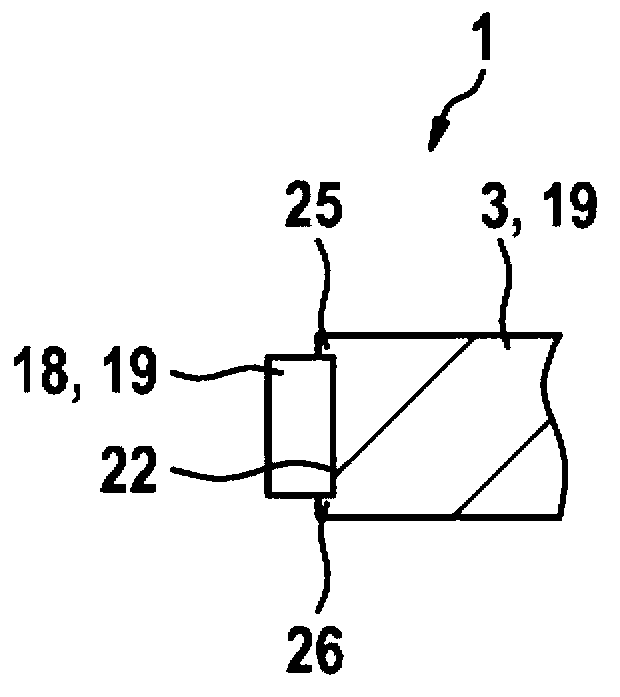

[0020] figure 1 A honing tool 1 and a workpiece 2 according to a first exemplary embodiment of the invention are shown schematically.

[0021] The honing tool 1 has a bar holder 3 ( figure 2 ), a honing tool body 3' and a cylindrical section 4 at which the honing tool 1 can be clamped in a chuck of a machine. For the sake of illustration, the honing tool 1 is inserted into a borehole 5 , which is designed as a blind borehole 5 . The blind bore 5 here has a widened section 7 at a lower end 6 . Furthermore, a borehole 8 with a reduced diameter is provided, which opens into the widened section 7 .

[0022] The widened section 7 predetermines a limited overrun 9 for machining the bore 5 with the honing tool 1 . The limited overtravel 9 is here limited by the stop of the lower end 10 of the honing tool body 3' on the lower end 6 of the widened section 7.

[0023] The honing tool 1 has a longitudinal axis 15 . The honing tool 1 is moved in the direction of the longitudinal ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com