Pad-type thrust bearing and rotary machine comprising such a thrust bearing

A technology of thrust bearings and liners, which is applied in the field of liner type thrust bearings and can solve problems such as fluid leakage and air bubble intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

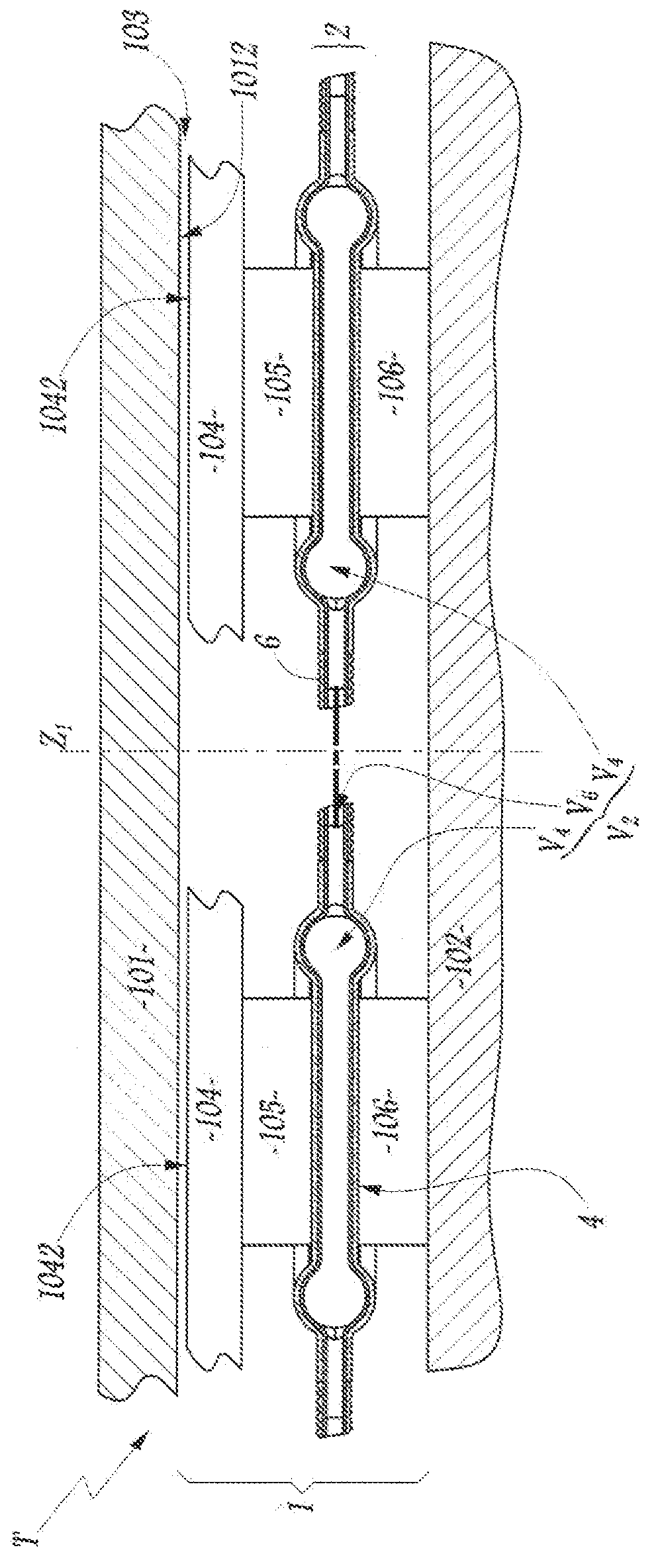

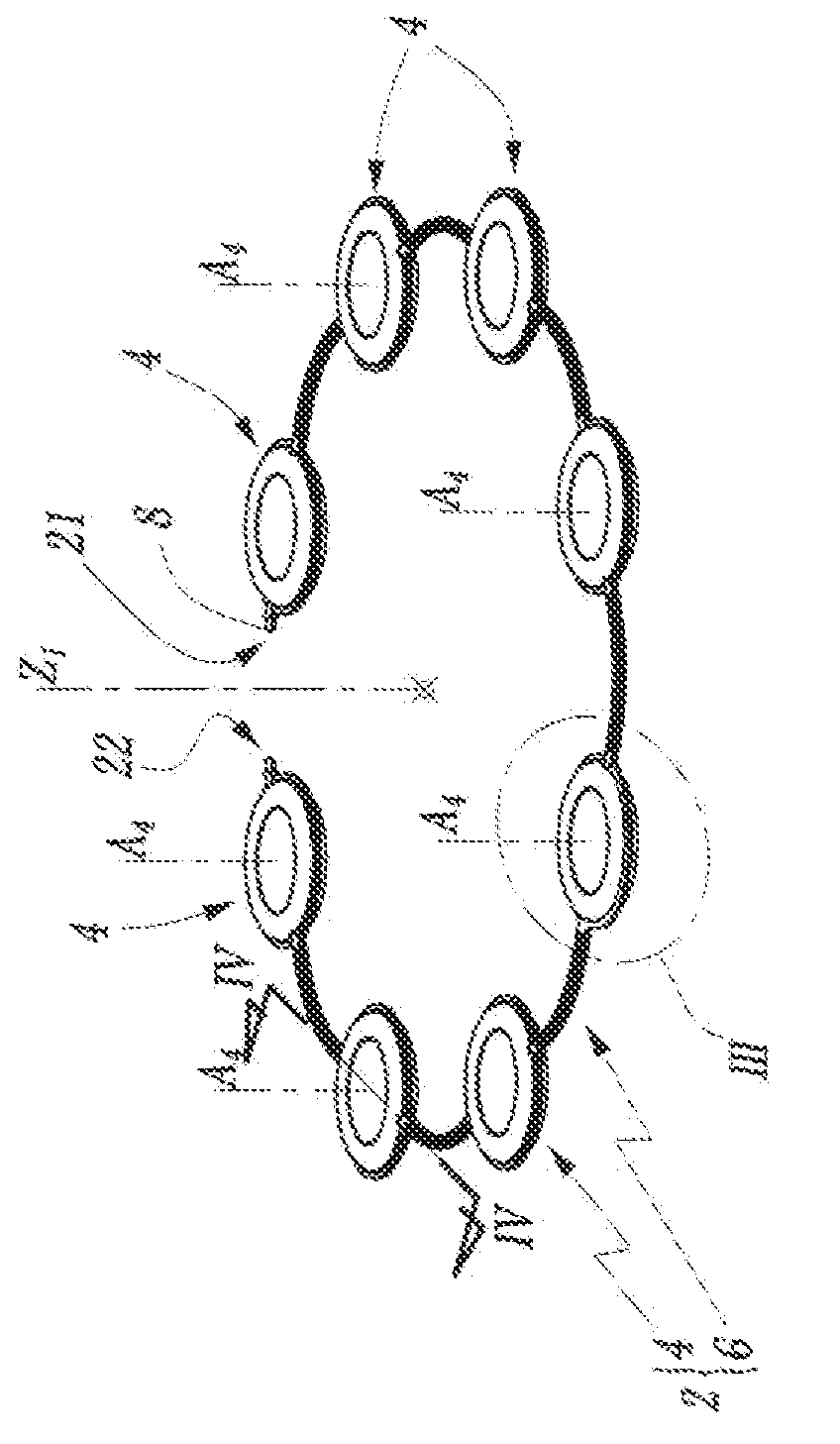

[0019] figure 1 The middle part shows a water turbine T comprising an annulus 101 that rotates integrally with the wheels of the turbine T, not shown, around a vertical axis Z when the turbine T is in operation 1 rotate. The ring 101 is supported relative to the fixed structure 102 by a bearing formed by an oil film 103 defined between the lower surface 1012 of the ring 101 and the upper surfaces 1042 of the eight pads 104, which 104 around axis Z 1 regular distribution.

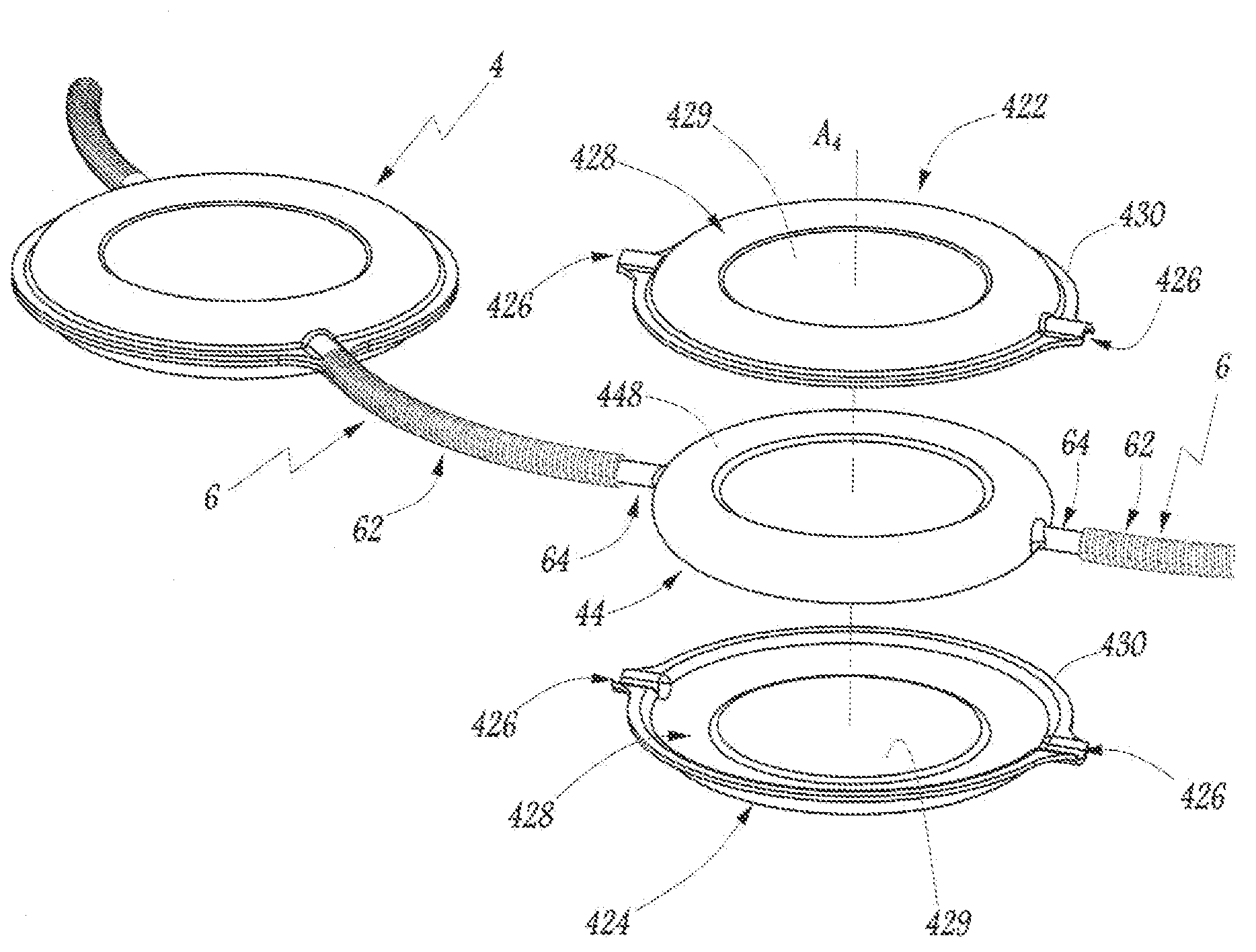

[0020] The pads 104 belong to the pad type thrust bearing 1 which makes it possible to adjust the height of the various surfaces 1042 relative to the structure 102 in order to guarantee the continuity of the oil film 103 . In addition to the pads 104 , the thrust bearing 1 also includes a load transfer block 105 and a shim 106 below each pad 104 , one of which is located below the other. Between each load transfer block 105 and the gasket 106 below the load transfer block 105 is equipped with a deformabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com