Clamp for local protection in chemical surface treatment of dental implant

A technology for surface chemical treatment and dental implants, applied in dentures, electrolytic components, electrolytic processes, etc., can solve the problems of shortening the service life of metal fixtures, easy peeling or breakdown of the coating layer, time-consuming problems, etc., to avoid corrosion and additional Low power consumption, easy cleaning and maintenance, and beautiful fixture shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

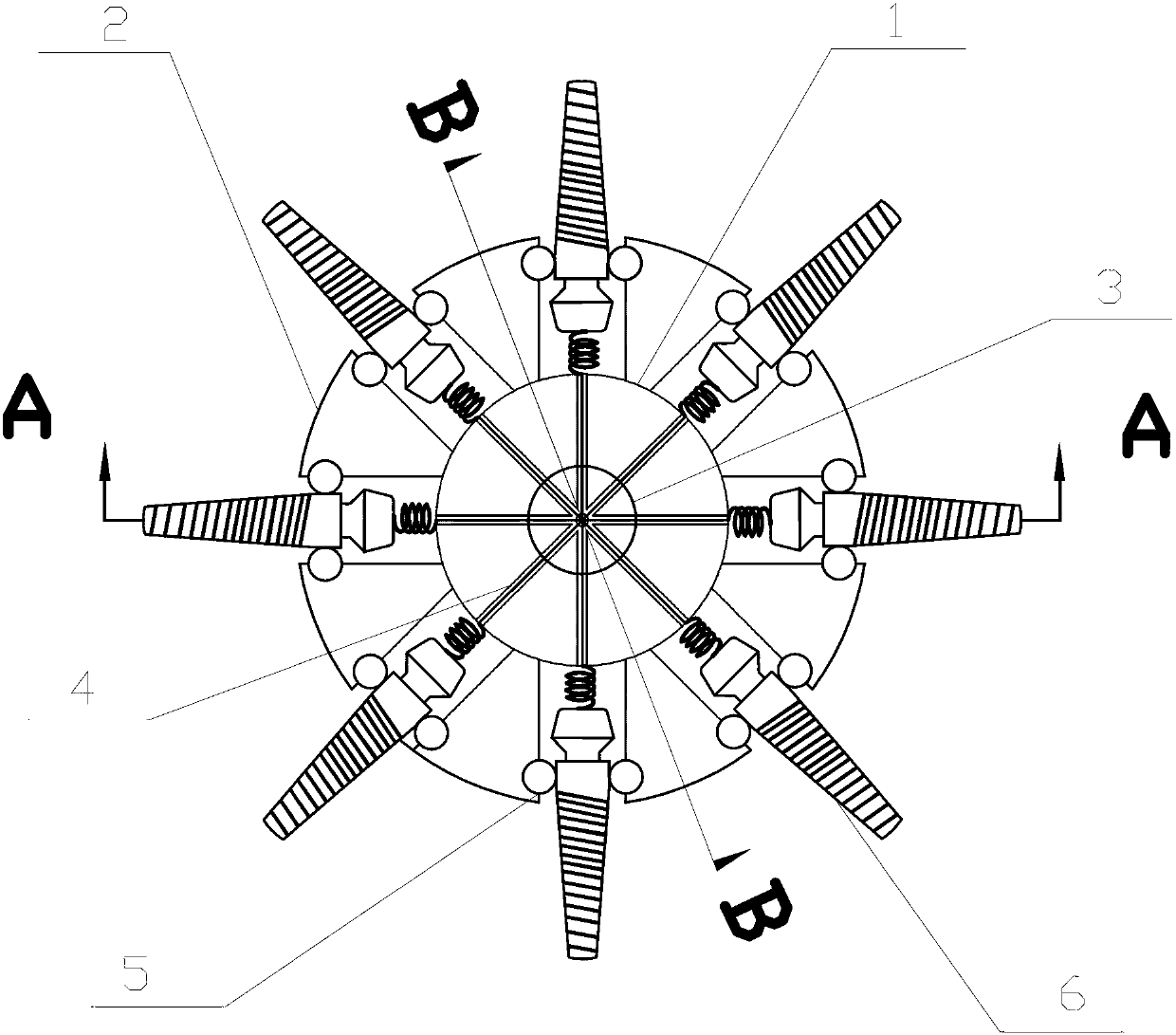

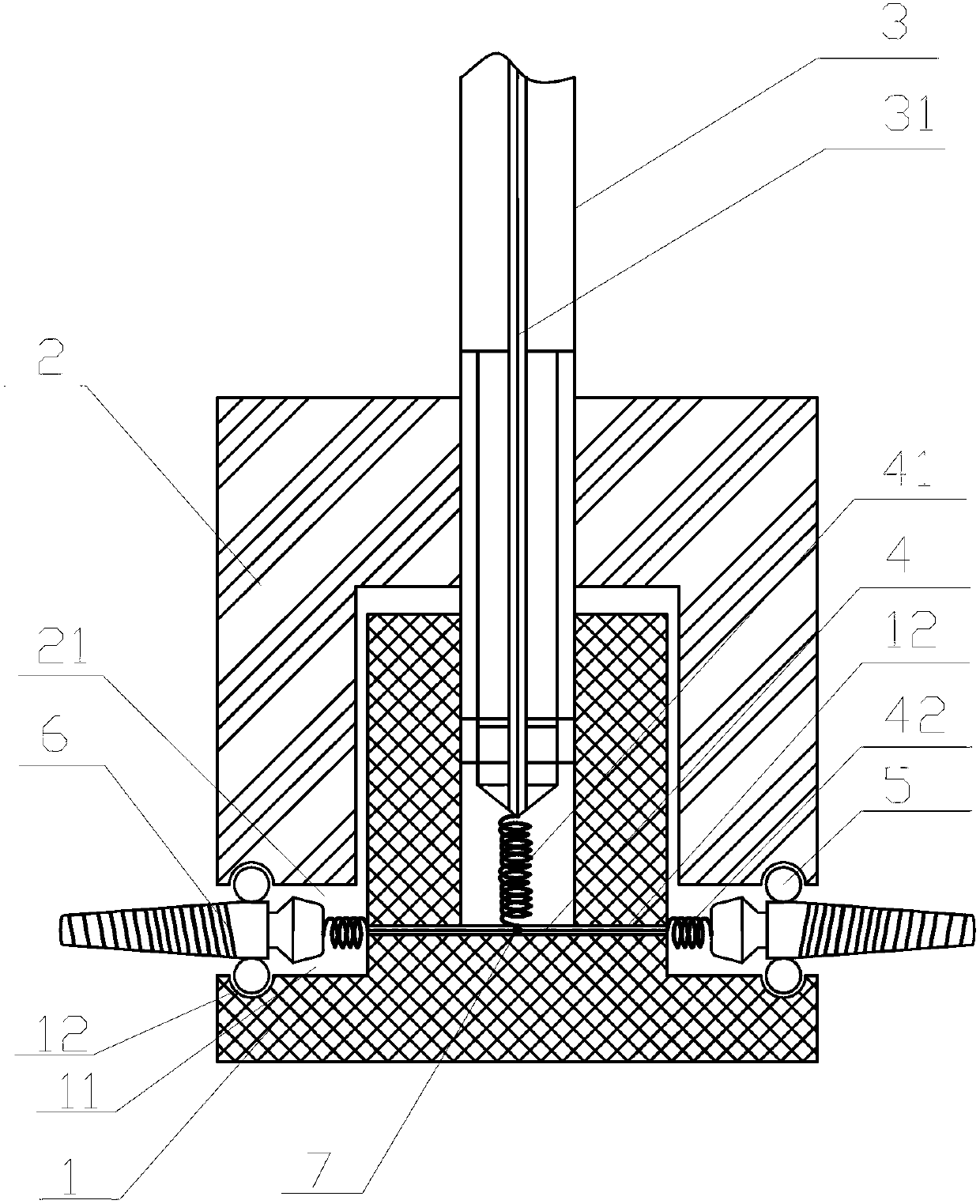

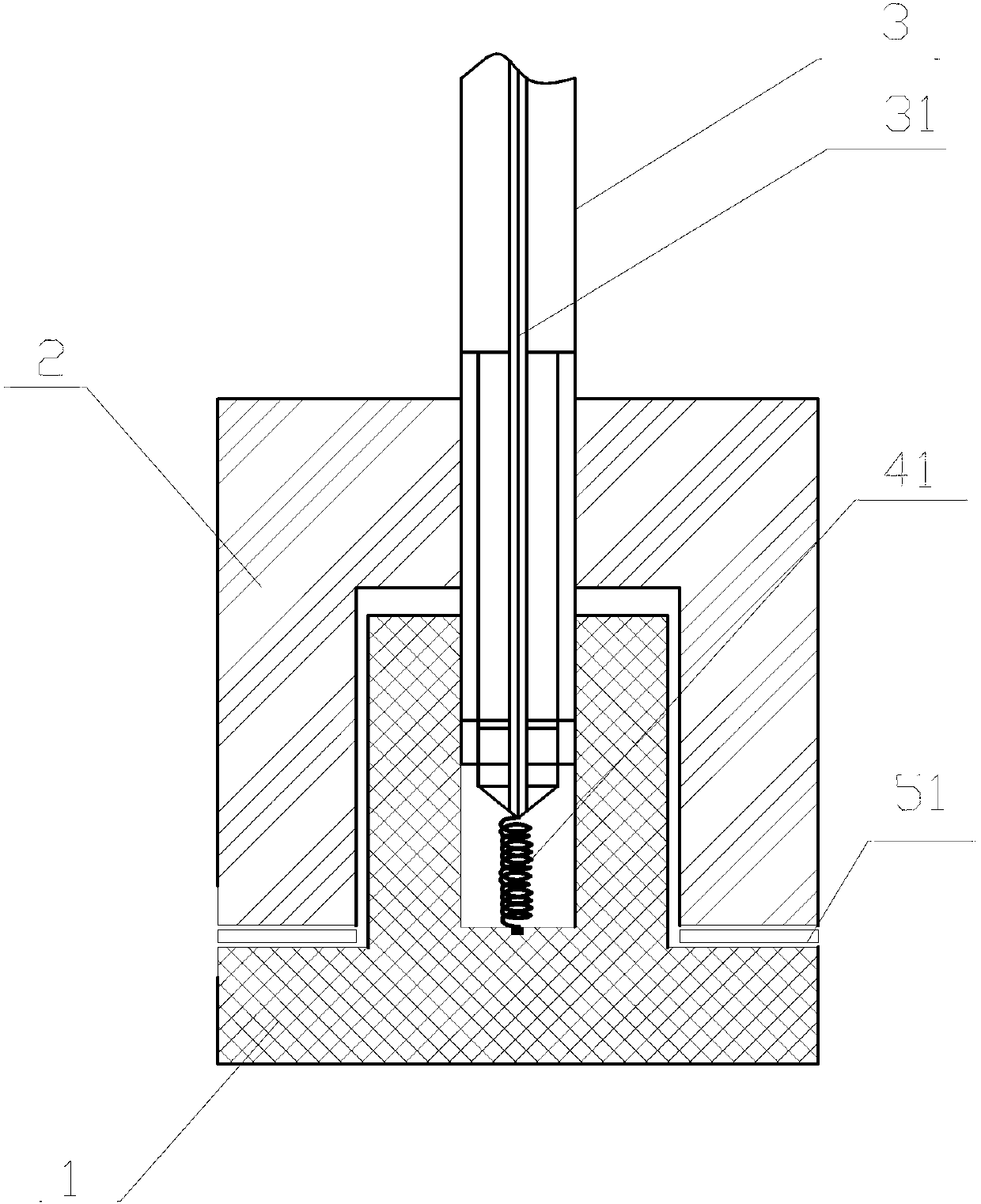

[0019] refer to Figure 1 ~ Figure 3 , a fixture used for local protection in the chemical treatment of the surface of dental implants, which includes a main body sealing seat 1, a sealing cover 2 and a fastening screw 3, and the upper end surface of the main body sealing seat 1 is evenly provided with several first Groove 11, the quantity of first groove 11 is 8, and described seal cover 2 is fixed on main body sealing seat 1 by fastening screw rod 3, and the lower end surface of seal cover 2 and first groove 11 form an open end The clamping cavity, the closed end of the clamping cavity is provided with a conductive device that can be connected to the power supply, and at least one annular sealing groove 12 is provided on the inner wall of the clamping cavity, and the sealing groove 12 is equipped with a The annular sealing ring 5 that clamps the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap