Tool change magazine for a motorized machine tool and machine tool

A tool replacement and machine tool technology, applied in the field of tool replacement library, to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

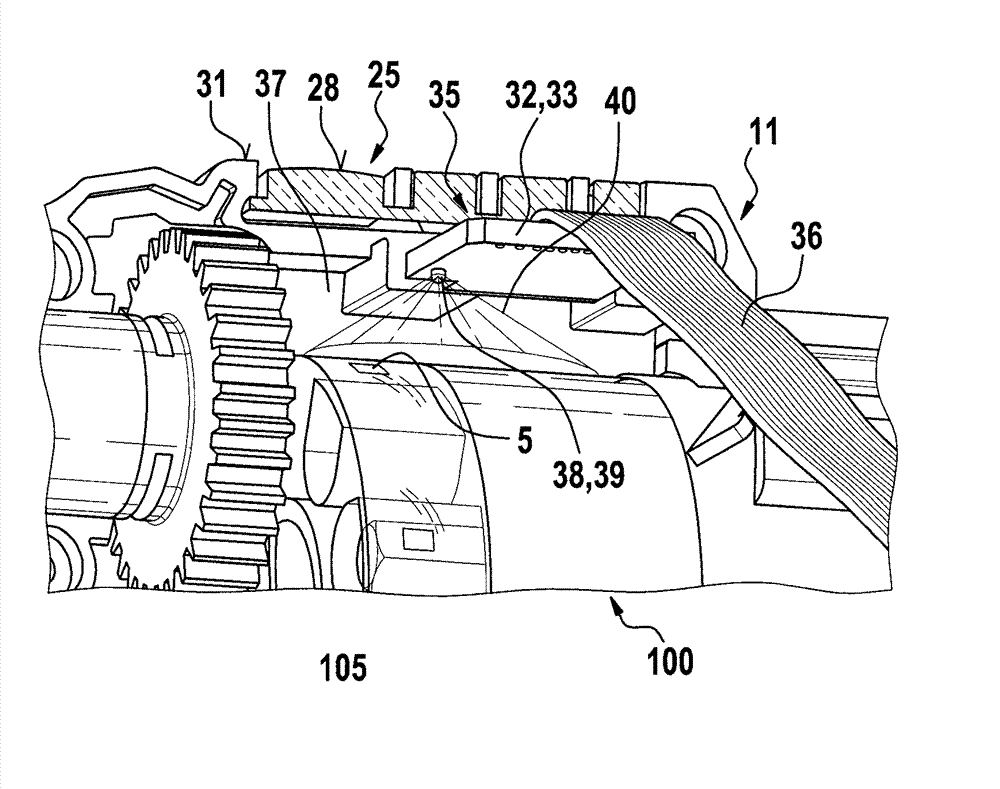

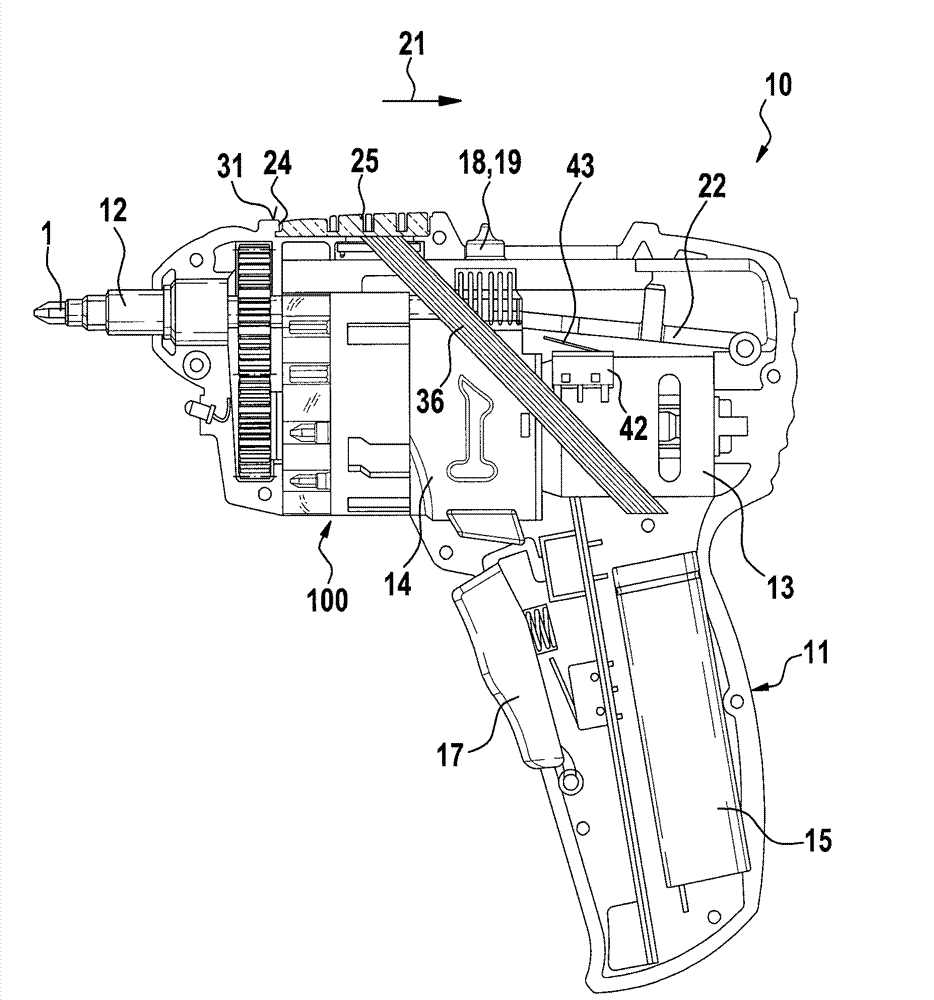

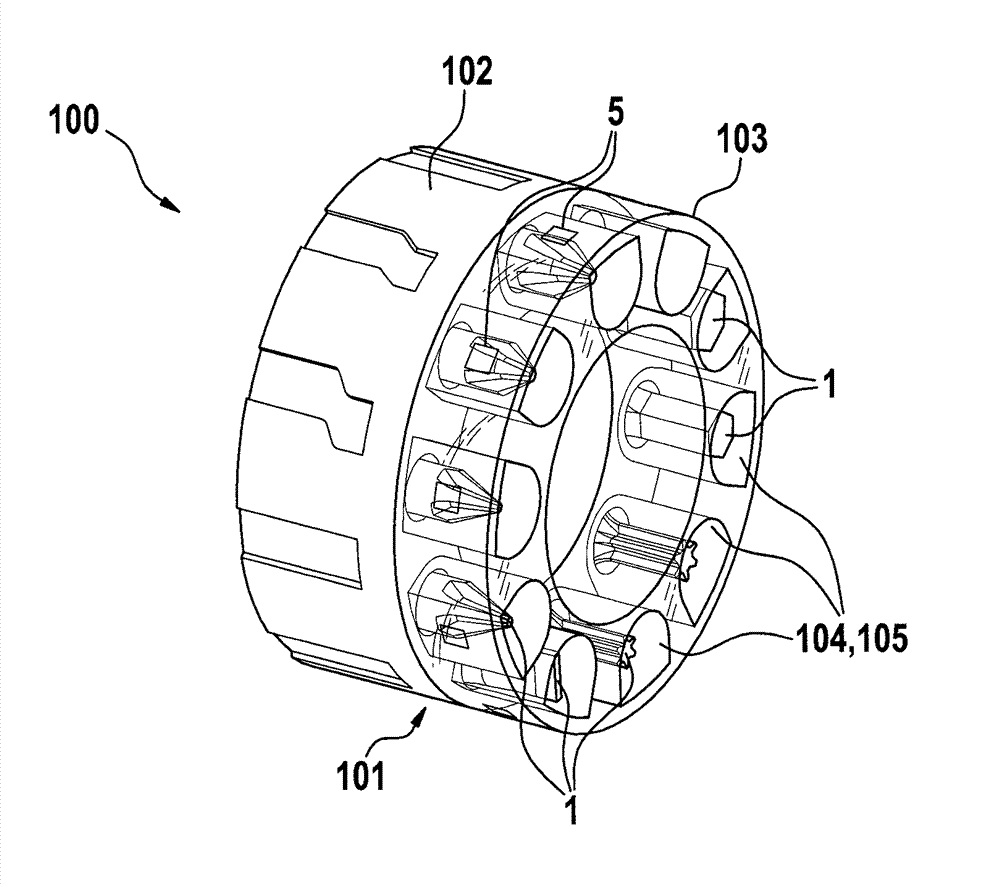

[0020] figure 1 A tool change magazine 100 according to the invention is shown. The tool changing magazine 100 has an annular or drum-shaped housing 101 rotatable along its longitudinal axis, which is divided into two parts in the longitudinal direction. The first housing part 102 is made of an opaque plastic material, while the second housing part 103 which is connected to said first housing part 102 in the longitudinal direction consists of a transparent plastic. The first housing part can be used for manual adjustment of a tool change magazine in machine tool 10 and is provided, for example, with grooves or the like for easy and precise adjustment of tool change magazine 100 for an operator. Furthermore, scratches or similar damage are not as noticeable from the outside as on housing part 103 , which is made of opaque plastic. In the interior of housing 101 , receiving openings 104 arranged at a uniform angular distance from one another are formed for receiving respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com