Petroleum asphalt anti-stripping agent, preparation method and use method thereof

A petroleum asphalt and anti-stripping agent technology, applied in the field of petroleum asphalt anti-stripping agent, can solve the problems of easy decomposition, affecting the anti-stripping effect, limited adsorption capacity, etc., to improve anti-aging, improve water damage resistance, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

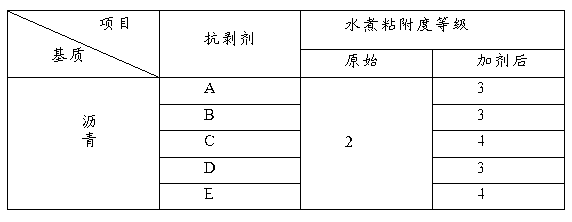

Embodiment 1

[0016] According to the ratio of 20 parts of fatty acid iron salt, 10 parts of calcium hydroxyphosphate, 5 parts of quaternary ammonium salt and 65 parts of gasoline, anti-stripping agent A is prepared by heating and melting. 0.5% of the anti-stripping agent prepared according to the proportion of the formula, after preliminary mixing, shear and stir with a high-shear emulsifier at a rate of 7000 r / min for 30 minutes, and the anti-stripping petroleum asphalt A can be obtained.

Embodiment 2

[0018] According to the proportion of 30 parts of fatty acid iron salt, 8 parts of hydroxy calcium phosphate, 6 parts of quaternary ammonium salt and 56 parts of gasoline, the anti-stripping agent A is prepared by heating and melting. 0.5% of the anti-stripping agent prepared according to the proportion of the formula, after preliminary mixing, shear and stir with a high-shear emulsifier at a rate of 7000 r / min for 30 minutes, and the anti-stripping petroleum asphalt B can be obtained.

Embodiment 3

[0020] According to the proportion of 25 parts of fatty acid iron salt, 5 parts of hydroxy calcium phosphate, 10 parts of quaternary ammonium salt and 60 parts of gasoline, the anti-stripping agent A is prepared by heating and melting. Anti-stripping asphalt C can be prepared by using a high-shear emulsifier at a rate of 7000 r / min for 30 min after preliminary mixing of 0.5% anti-stripping agent prepared according to the formula ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com