Quick-release lock and application method thereof

A lock box and lock lever technology, applied in the direction of building fasteners, wing fan fasteners, buildings, etc., can solve the inconvenience of use by flight attendants in aircraft ground maintenance work, affect aircraft safety, and aircraft attendance, and the opening process is cumbersome. and other problems, to achieve the effect of flexible opening and closing operation, hidden and beautiful appearance, and reduction of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

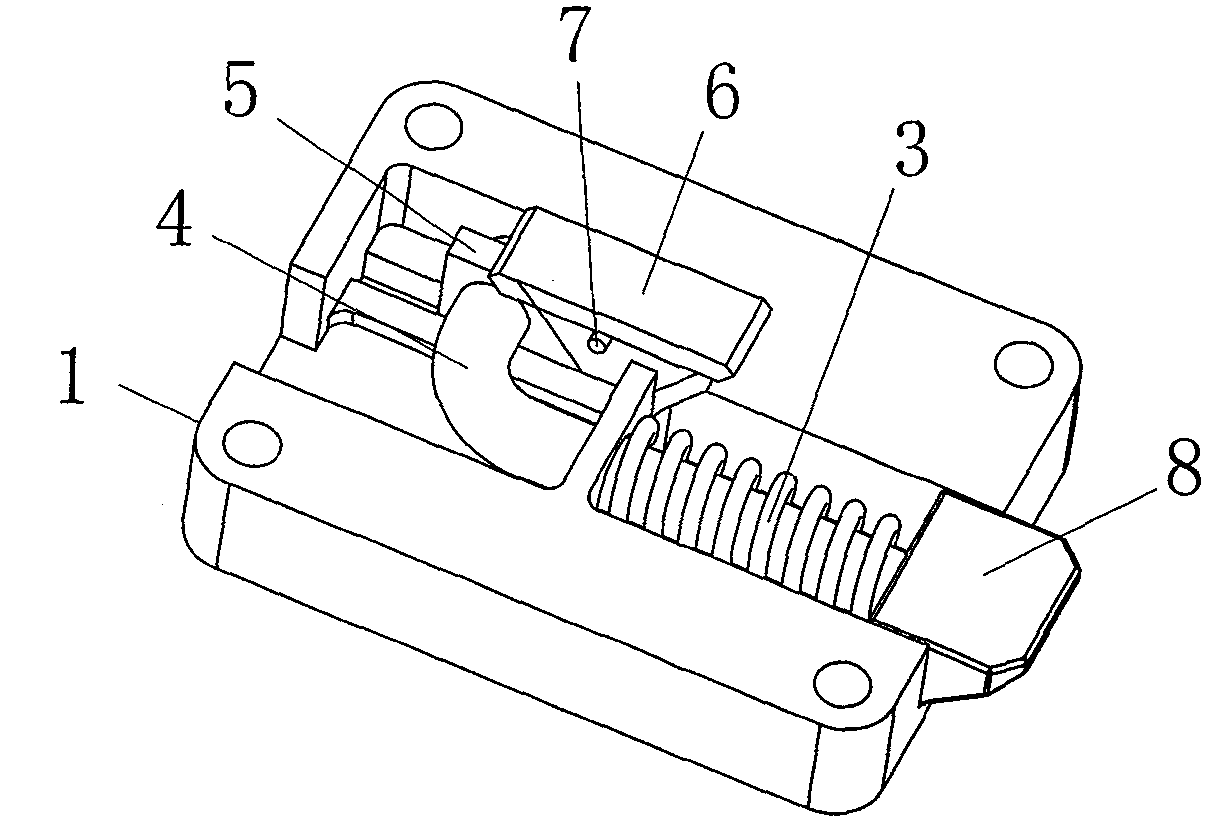

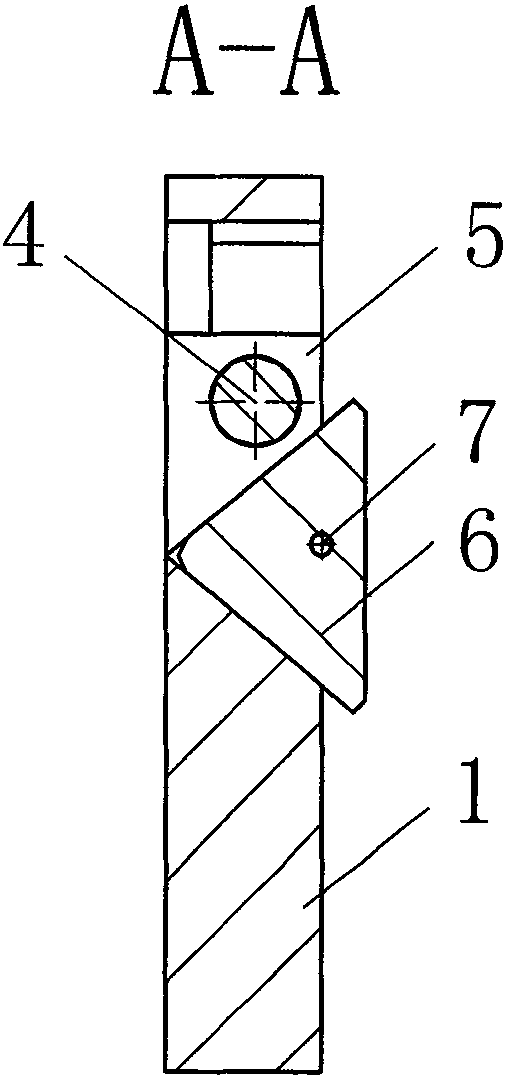

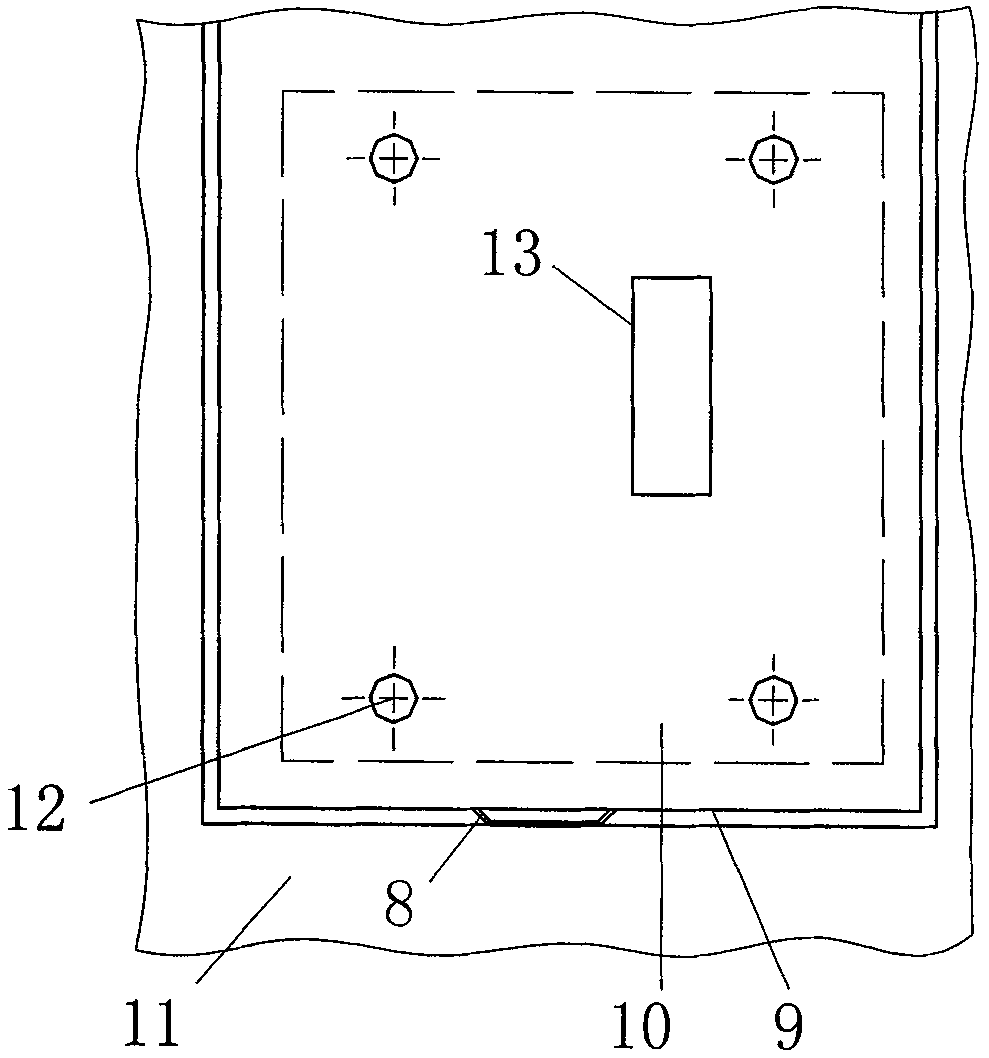

[0017] See attached figure 1 In the implementation, lock box 1 and lock cover 2 are made of LY12-BCZYU plate; spring 3 is made of HB3-1-0.5×5×22II; lock rod 4 is made of 30CrMnSiA bar; slider 5 and button 6 are made of LY12-BCZYU plate; positioning Pin 7 is made of 30CrMnSiA bar; bolt 8 is made of LY12-BCZYU; plate fastener 12 is used (bolt 4A1-22-4×L, washer 4A1-175-4×8×1, nut 4A-41-4). All except spring 3 and fastener 12 are made by machining.

[0018] The assembly relationship of the quick release lock of the present application is as follows: figure 2 As shown, the lock bar 4 is an L-shaped bar structure, the lock bar 3 is inserted in the guide hole in the middle of the lock box, the front end is fixed with a lock tongue 8, and the spring 3 is sleeved on the lock bar behind the lock tongue and embedded in the lock In the lock groove of the box 1, the other end of the lock rod 4 is plugged into the connection hole of the slider 5, so that the slider, the lock rod and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com