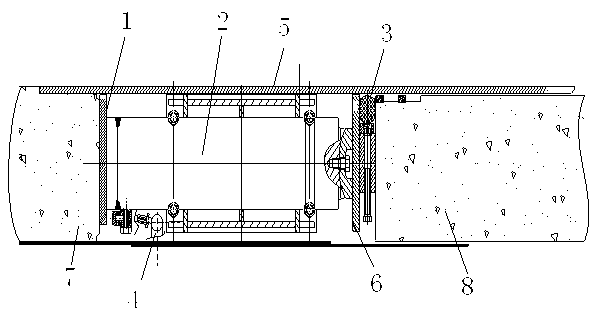

Assembled jacking pipe relaying intermediate

An assembled and pipe-jacking technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficult cutting and dismantling of relay cylinders, high production costs, and difficult replacement of sealing devices, etc., to achieve The production cost is low, the project cost is saved, and the water-stop effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The project uses φ4640 concrete pipe jacking construction, the pipe is the largest diameter pipe jacking in China, and the single jacking length reaches 2039.82m, which is the longest distance pipe jacking with the same diameter. The whole line of the project is double-line parallel curved jacking. With such a long distance and such a large diameter of concrete pipe jacking, the total jacking force of the backseat is extremely huge, and relay jacking is required to ensure the safe and smooth implementation of the project. According to the design calculation, one pipe is arranged every 70m to 140m The relay ring has a large number of relay rings.

[0019] It has been proved by engineering practice that during the jacking construction process, the sealing device has good water-tight performance, and the damaged sealing device is replaced under normal pressure, which is extremely easy to replace, and the removal of the sealing device is also extremely convenient after jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com