How to measure the focal length of a convex lens

A measurement method, convex lens technology, applied in the direction of testing optical performance, etc., can solve the problems of inaccurate measurement of image distance, error of lens focal length, inaccurate measurement of object distance, etc., achieve accurate object distance and image distance, eliminate human error, and facilitate observed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

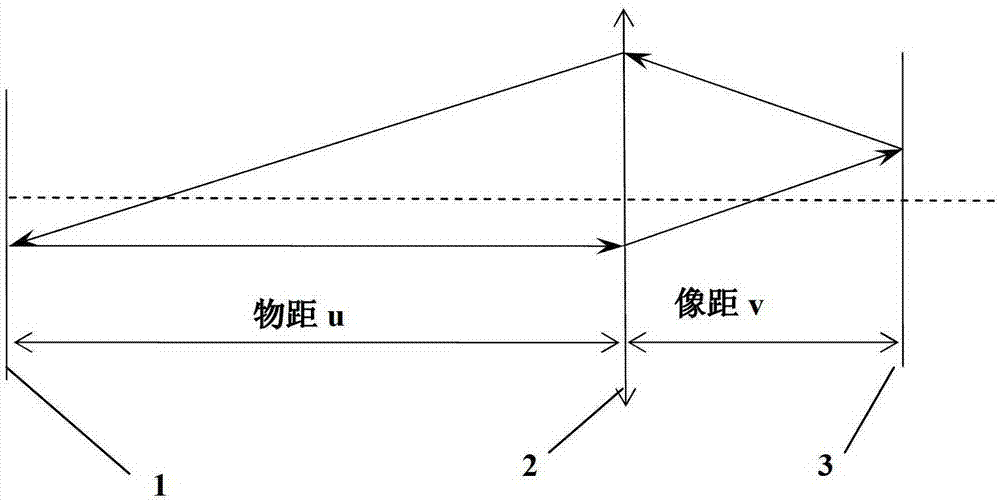

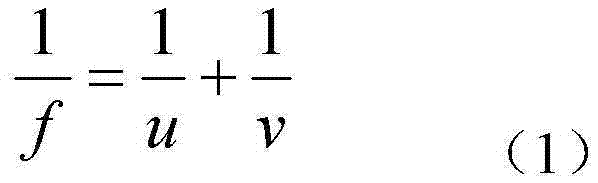

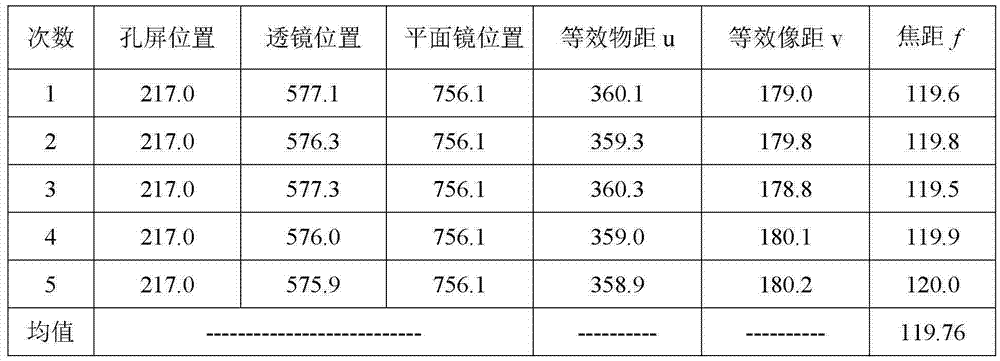

[0023] The inventive idea of the present invention is: use the light emitted by a laser and the light reflected by the plane mirror to form a light circuit, and the small holes on the hole screen and the light spots on the plane mirror can be regarded as equivalent objects and images.

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The measuring method of convex lens focal length of the present invention comprises the following steps:

[0026] 1. Place the laser, hole screen 1, convex lens 2, and plane mirror 3 on the light guide rail, and adjust the coaxiality; the laser light emitted by the laser can pass through the small hole on the hole screen 1.

[0027] 2. Fine-tune the horizontal direction of the slider on the optical bench where the convex lens 2 is installed, so that the horizontal direction of the convex lens 2 is a certain distance away from the axis. On the basis of ensuring that the experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com