Write-through lithography processing system and lithography method

A lithography processing and direct writing technology, applied in the field of lithography, can solve the problems of low processing efficiency and high cost of precision optical scanning device equipment, and achieve the effect of low coherence requirements and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

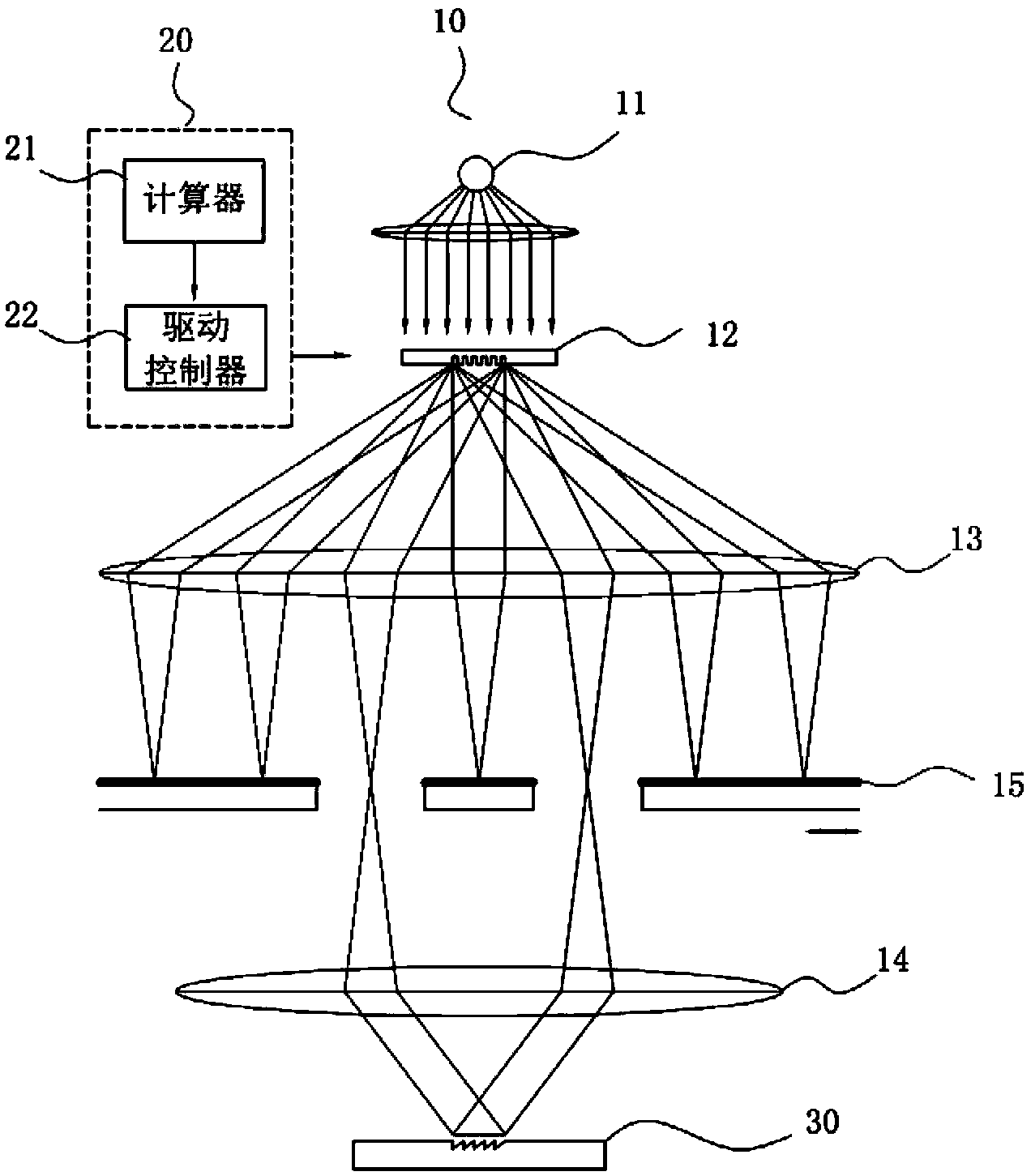

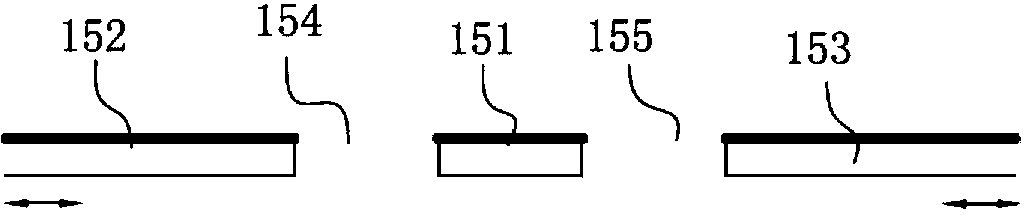

[0050] See figure 2 , figure 2 It is a structural schematic diagram of the direct writing photolithography processing system of the present invention. As shown, the system includes an exposure system 10 and a control system 20 . The exposure system 10 is essentially an exposure optical path for producing two-beam interference exposure, including a light source 11 , a spectroscopic device 12 , a first optical mirror group 13 , an iris diaphragm 15 and a second optical mirror group 14 . The exposure system 10 composes the exposure optical path in the order of a light source 11 , a spectroscopic device 12 , a first optical mirror group 13 , an iris diaphragm 15 and a second optical mirror group 14 .

[0051] In a preferred embodiment, the light source 11 adopts a laser, which has the advantage that the laser has good coherence and is suitable for interference lithography. In addition, compared with ordinary light sources, laser has good uniformity of light field. The use of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com