nor flash memory, method for forming the same, and method for forming a contact hole

A memory and contact hole technology, which is used in the manufacture of electrical solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of leakage current, insignificant leakage current of NOR flash memory, and dielectric layer breakdown, etc. The effect of expanding the minimum distance, reducing leakage current and small line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

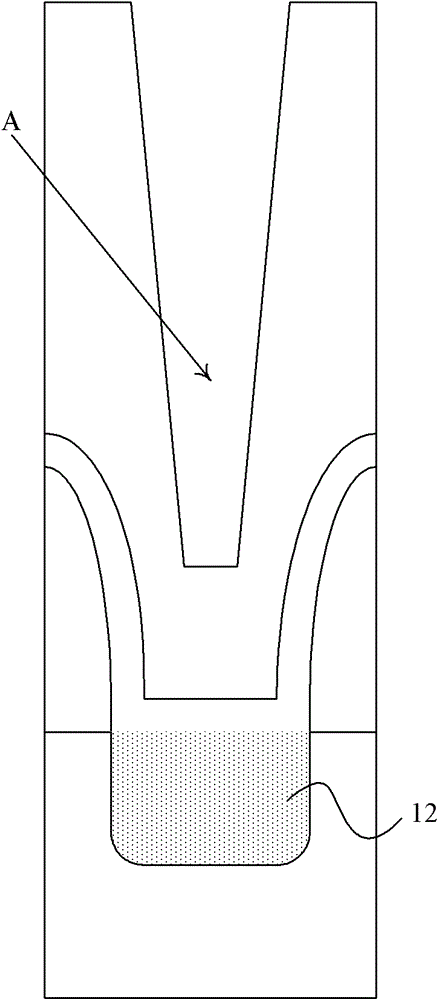

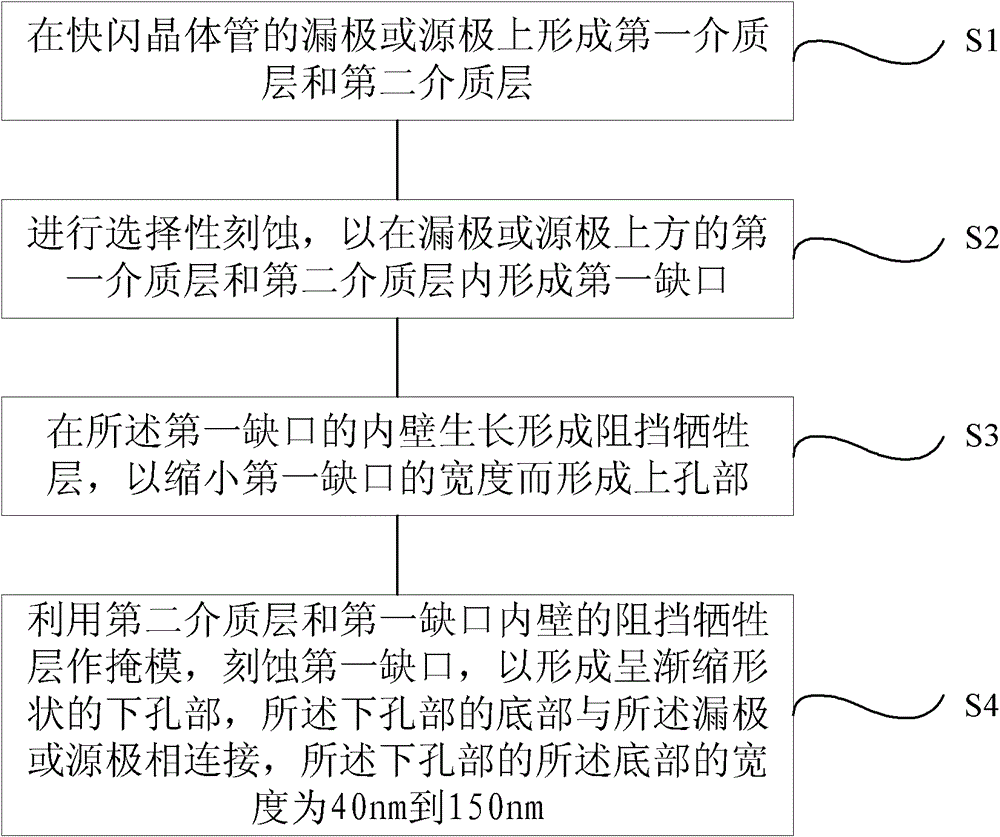

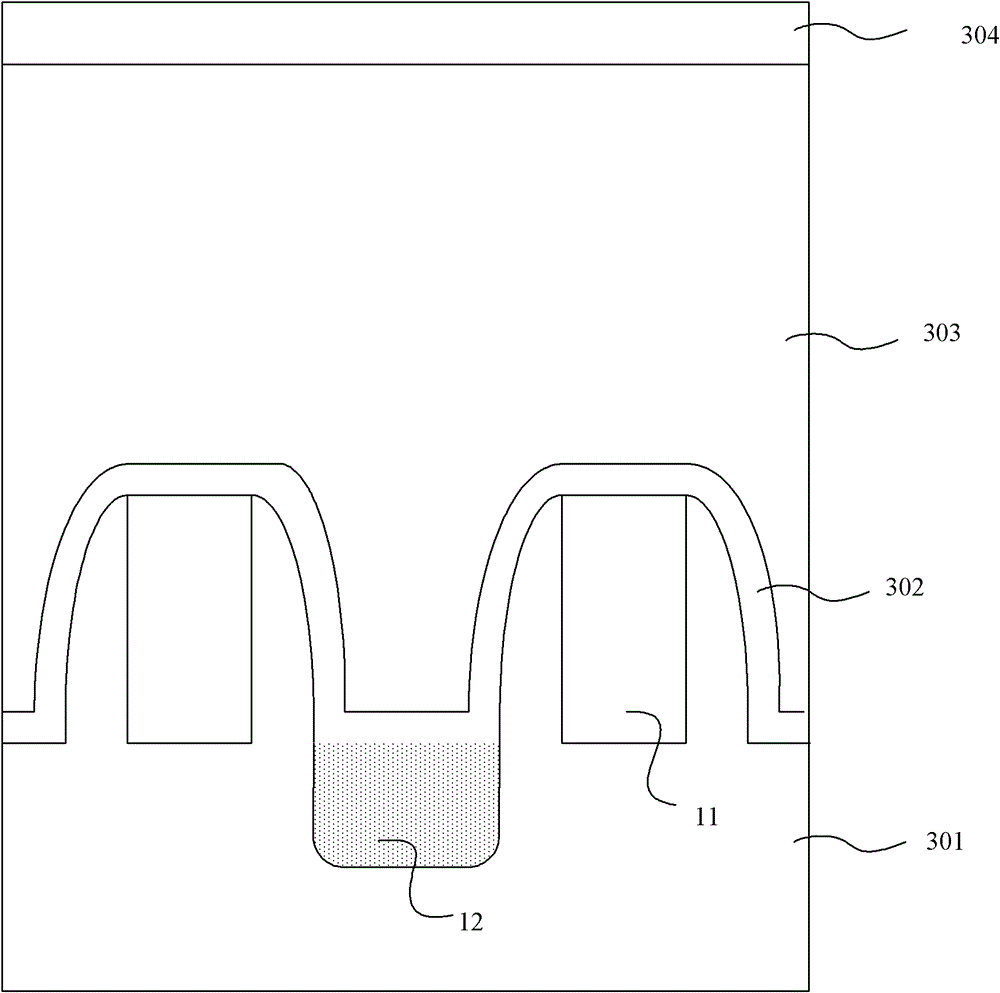

[0059]As mentioned in the background art, when the NOR flash memory operates at high voltage for erasing and writing, electrons from the source are accelerated to the drain, and then electrons are injected from the drain to the floating gate. In such a process, leakage current is easily generated between the drain and the gate due to high voltage.

[0060] After research, it is found that the leakage current is mainly concentrated between the data line (Bit-line) connected to the drain and the control line (Word-line) connected to the gate. The inventor believes that due to the continuous reduction of the critical dimensions of integrated circuits, the minimum distance between the contact hole on the drain electrode and the gate, especially between the data line (Bit-line) and the control line (Word-line) is getting more and more Small, the dielectric layer between them is more prone to leakage under high voltage. Therefore, a key to solve this problem is to enlarge the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com