Vehicle seat

一种车辆座椅、座椅的技术,应用在车辆座椅、座椅架、车辆部件等方向,能够解决无法充分传递负载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

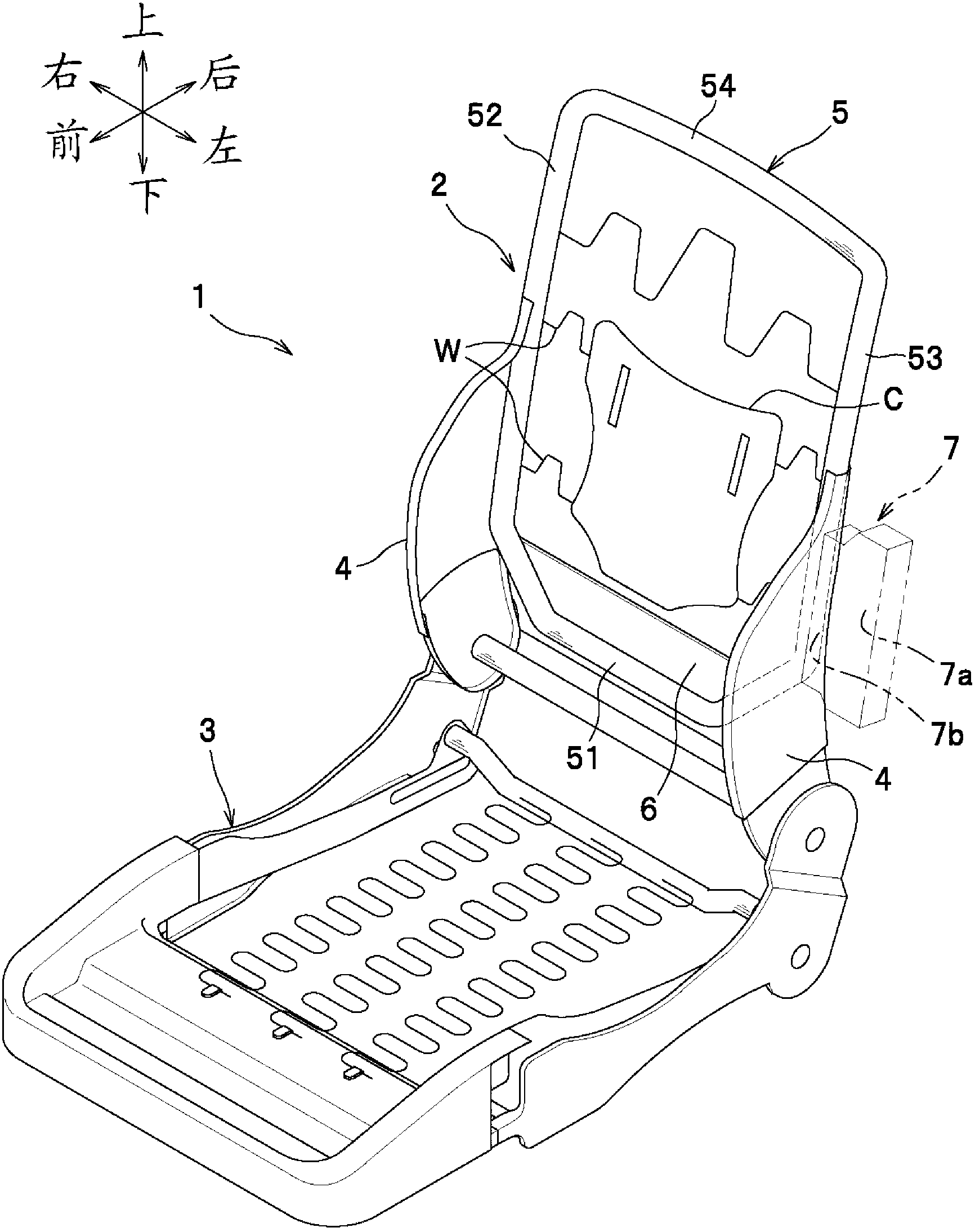

[0022] According to the present invention, the vehicle seat is composed of such as figure 1 The shown seat frame 1 is formed of a seat frame 1 covered on the outside with a seat cushion made of polyurethane foam or similar material. The seat frame 1 includes a seat back frame 2 and a seat bottom frame 3 . It is not difficult to understand that in the description of the present invention, the front / rear, left / right and up / down directions are stipulated as taking the view angle of the occupant sitting on the seat as the criterion.

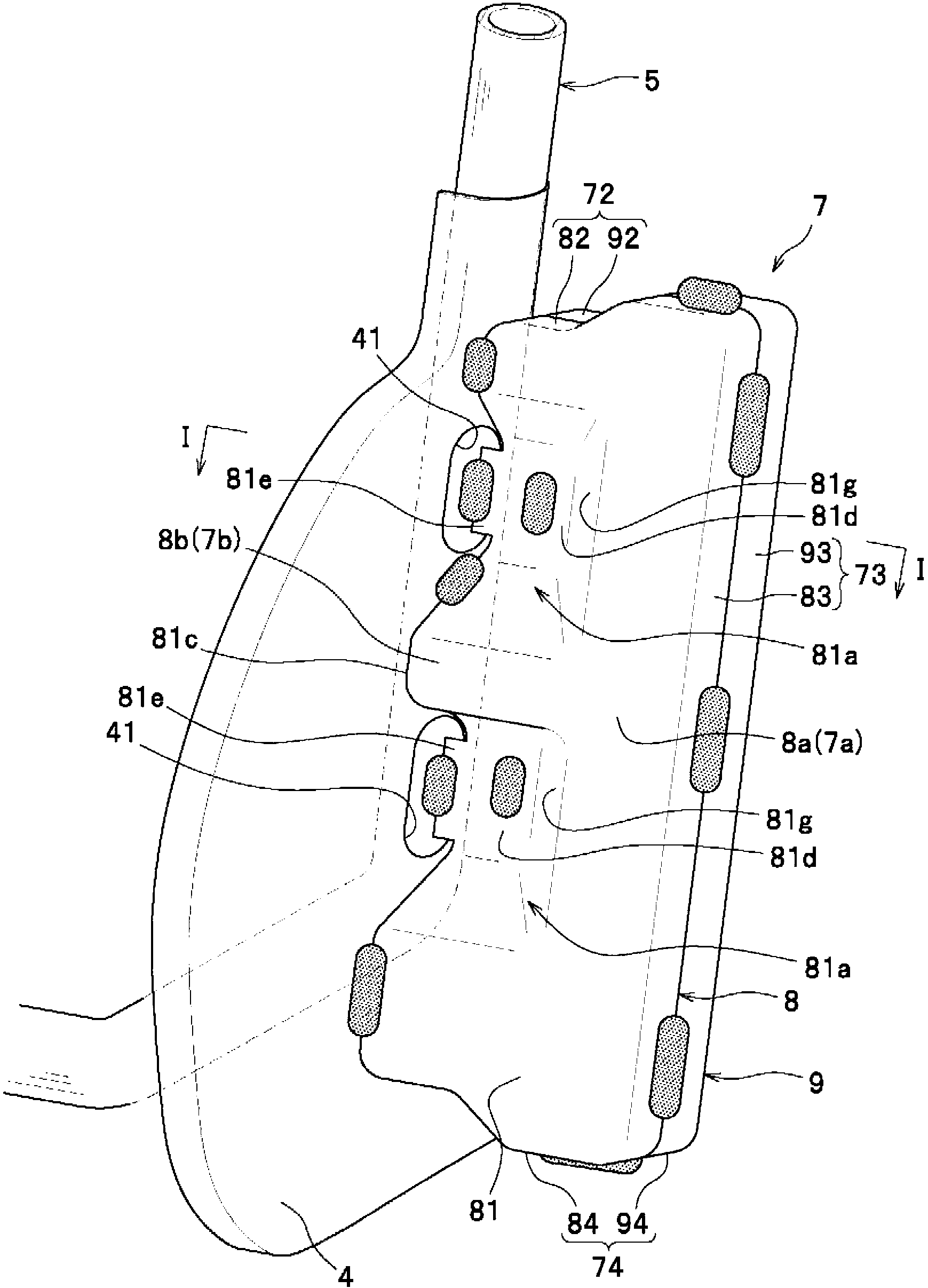

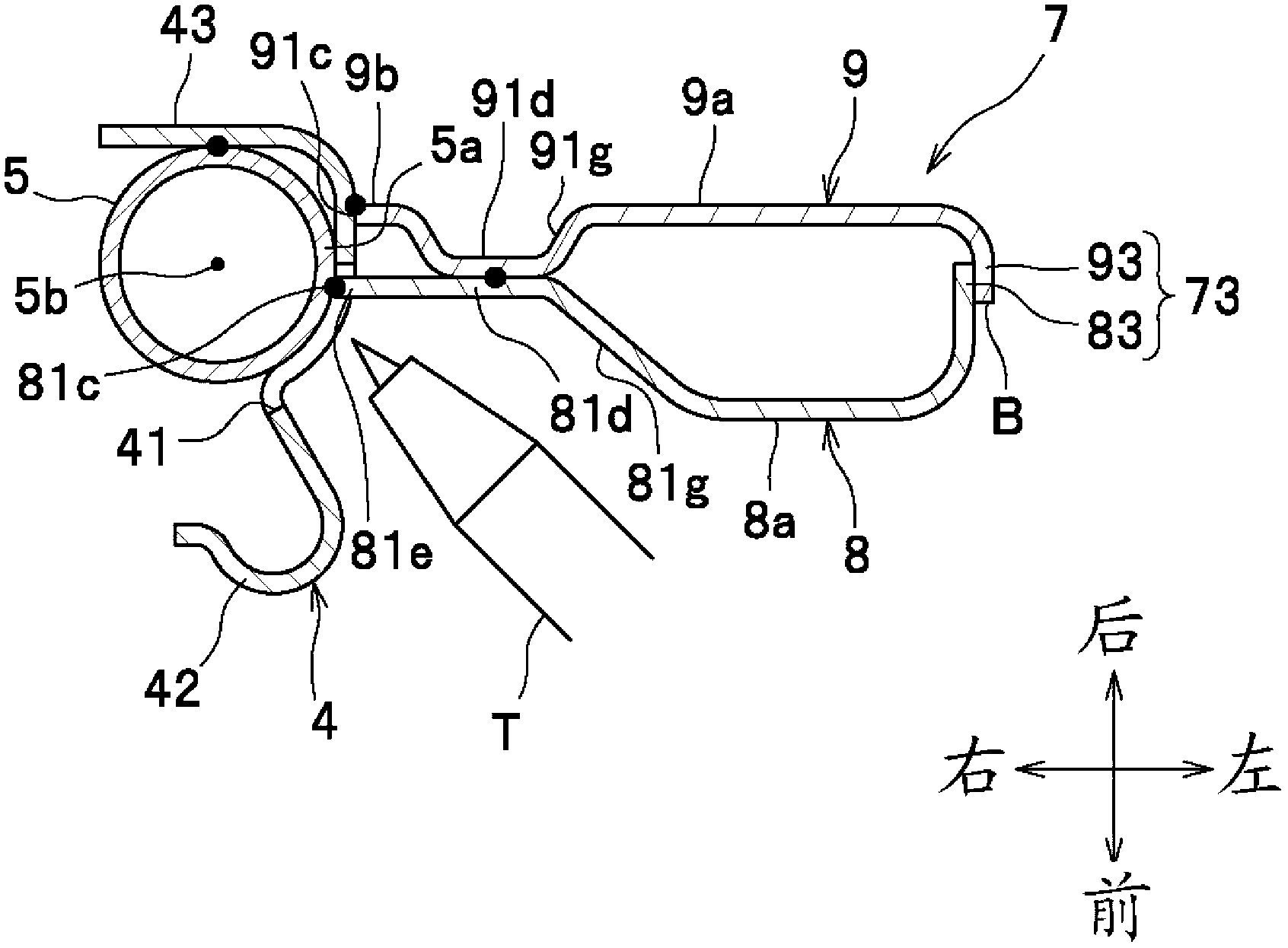

[0023] The seat back frame 2 includes a pair of side frames 4 , a pipe frame 5 as a reinforcing frame for reinforcing the side frames 4 , a bottom frame 6 , and a bracket 7 as an example of a force receiving member.

[0024] The shape of the pipe frame 5 is a cylindrical pipe (with a closed section) bent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com