Method for reducing the drive slip in vehicles with multiple engines

A technology of motors and vehicles, which is applied to the arrangement of multiple different prime movers, vehicle components, brakes, etc. of general power plants, and can solve the problems of signal transmission consumption, damage to ASR-regulation, and inability to provide real-time signal values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

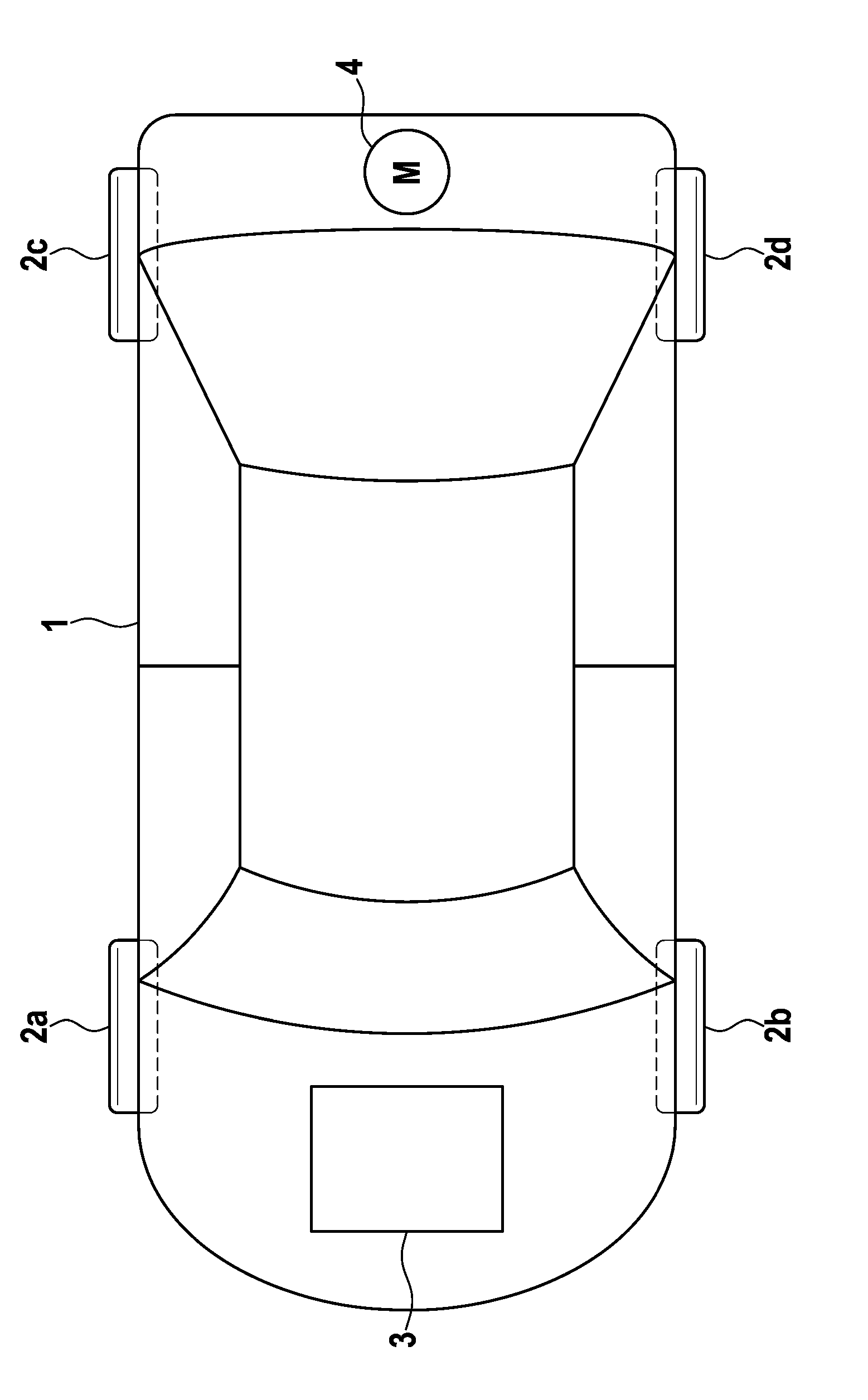

[0013] figure 1 A vehicle 1 is shown in a schematic block diagram with an internal combustion engine 3 for driving the front axle and an electric motor 4 for driving the rear axle. The wheels of the front axle are marked with 2a, 2b, the wheels of the rear axle with 2c, 2d.

[0014] In order to reduce the drive slip of the wheels 2 a - 2 d during acceleration, it is provided that slip regulation is carried out at the front wheels 2 a , 2 b and slip control is carried out at the rear wheels.

[0015] The coefficient of friction [mu] is estimated in a conventional manner when the slip adjustment is carried out at the front wheels 2a, 2b. From this, the drive torque for the electric motor 4 can be calculated, which can be maximized on the road surface. The electric motor 4 is now controlled in such a way that it produces a portion of the maximum achievable drive torque. The proportion of the drive torque that can be formed can be, for example, between 80% and 90%, or even less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com