Semi-submersible vessel and its operation method

A semi-submersible ship and operation technology, applied in the direction of hull, icebreaker, ship construction, etc., can solve problems such as waters that are not suitable for freezing, and achieve the effect of reducing the risk of problems caused by ice substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

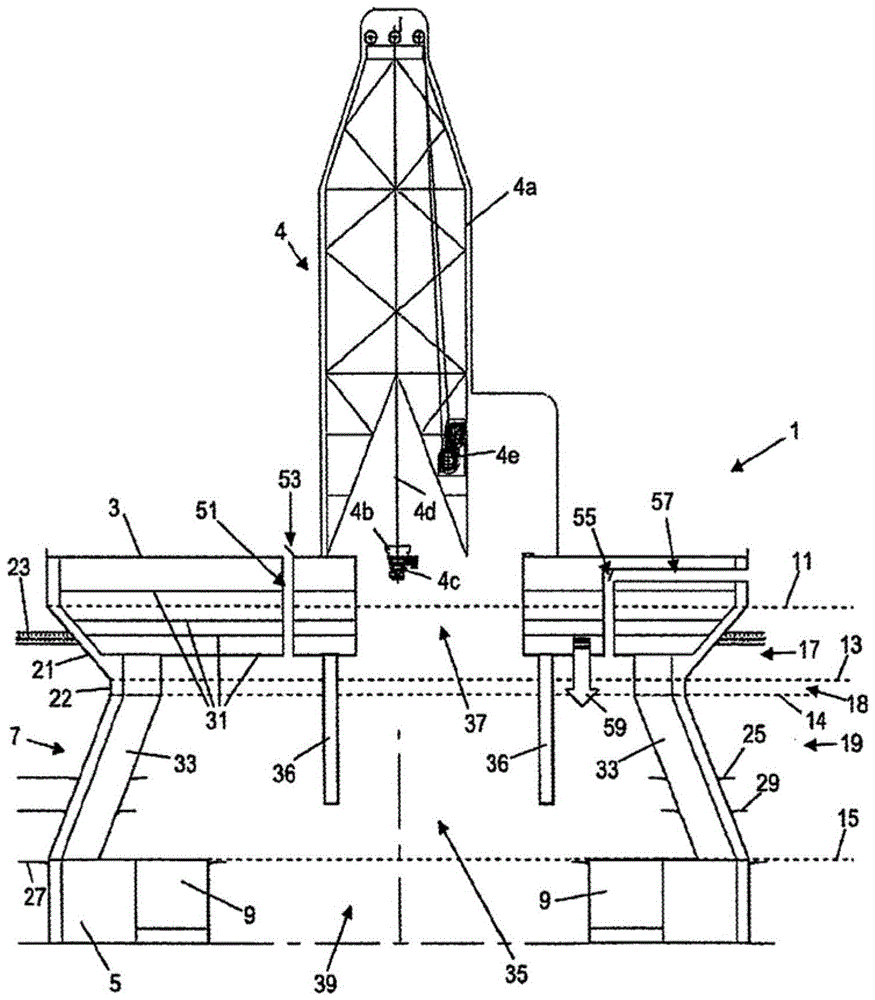

[0088] figure 1 A vertical section of a semi-submersible vessel 1 according to an embodiment of the invention is shown. The semi-submersible vessel 1 includes a working deck 3 for accommodating equipment. In this embodiment, the apparatus comprises a drilling rig 4 having a tower 4a and hoisting means comprising a load coupling 4b of a fixed top drive 4c, a hoisting line 4d, and a hoisting winch 4e. The tower 4a may have a closed wall of circular cross-section in plan view. In this embodiment, the main part of the tower is therefore cylindrical. At the top of the cylinder, a tapered portion is provided.

[0089] The semi-submersible vessel 1 further comprises a pontoon 5 and a substantially vertical connecting structure 7 between the pontoon 5 and the working deck 3 .

[0090] At different heights of the connecting structure, horizontal dotted lines 11, 13, 14, 15 are drawn to show different parts of the connecting structure. Between the dotted lines 11 and 13 there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com