Slurry cooking tower

A technology of boiling pulp and gallbladder, which is applied in the direction of milk substitutes, dairy products, applications, etc., can solve the problems of low energy consumption and inability to meet the needs of industrial production, and achieve the effect of good quality, large output, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

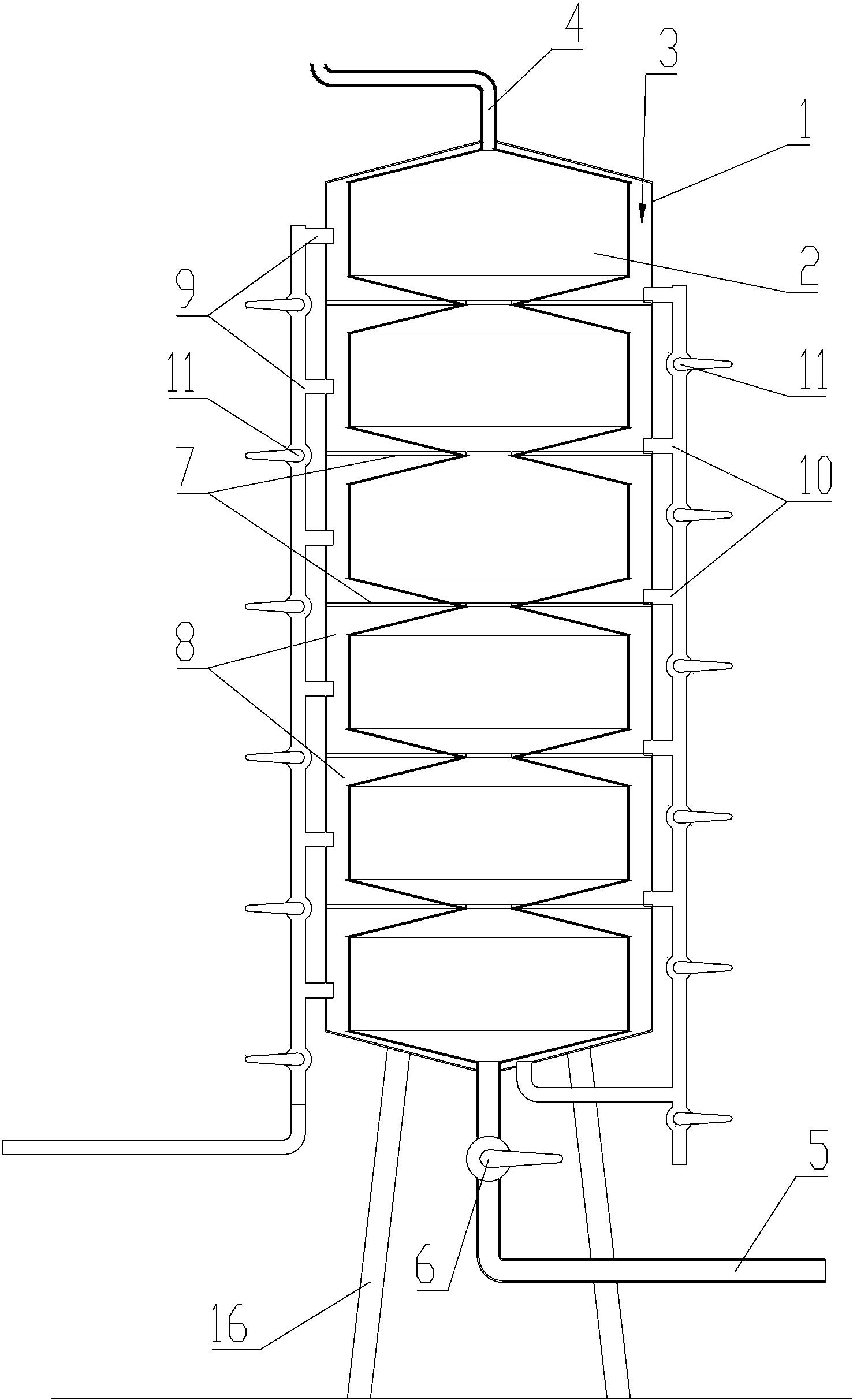

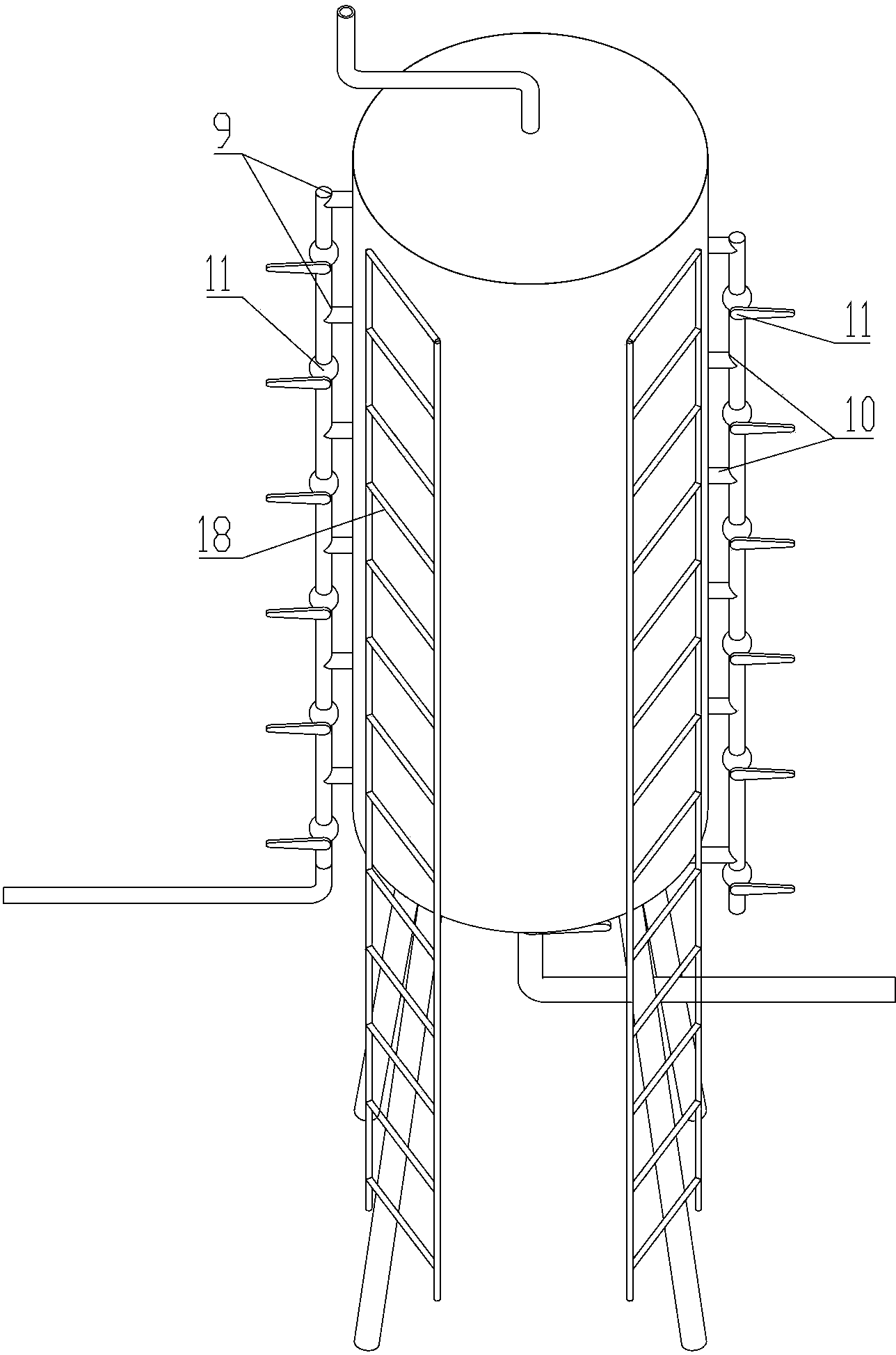

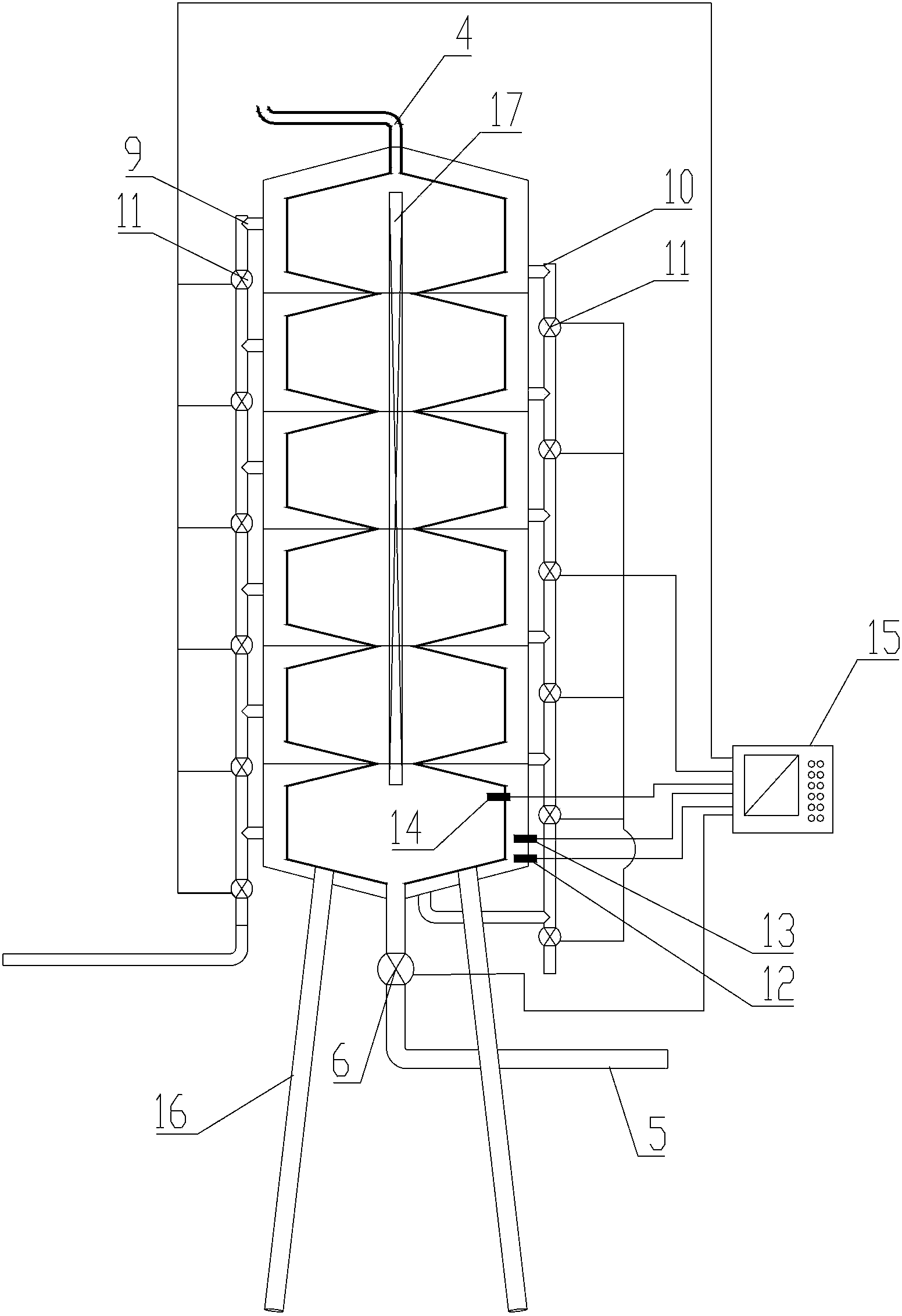

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the pulp cooking tower of the present invention includes a tower shell 1, a tower gall 2 arranged inside the tower shell 1 and a support 16 arranged at the bottom of the tower shell 1, so A steam interlayer 3 is formed between the tower shell 1 and the tower gall 2, the top of the tower gall 2 is provided with a feed pipe 4, the bottom of the tower gall 2 is provided with a discharge pipe 5, and the discharge pipe 5 is provided with a discharge pipe 5. Valve 6, a plurality of partitions 7 are arranged between the tower shell 1 and the tower bile 2 to separate the steam interlayer 3 from top to bottom into a plurality of mutually independent heating chambers 8; the tower shell 1 corresponds to each Each heating chamber 8 is provided with an air intake pipe 9 and a waste discharge pipe 10 respectively.

[0023] When working, the discharge valve 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com