Three-dimensional forming device and method, setting data creation device and program for the three-dimensional forming device

A three-dimensional forming and equipment technology, applied in metal processing equipment, 3D object support structure, manufacturing tools, etc., can solve the problems of easy removal and peeling of support materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

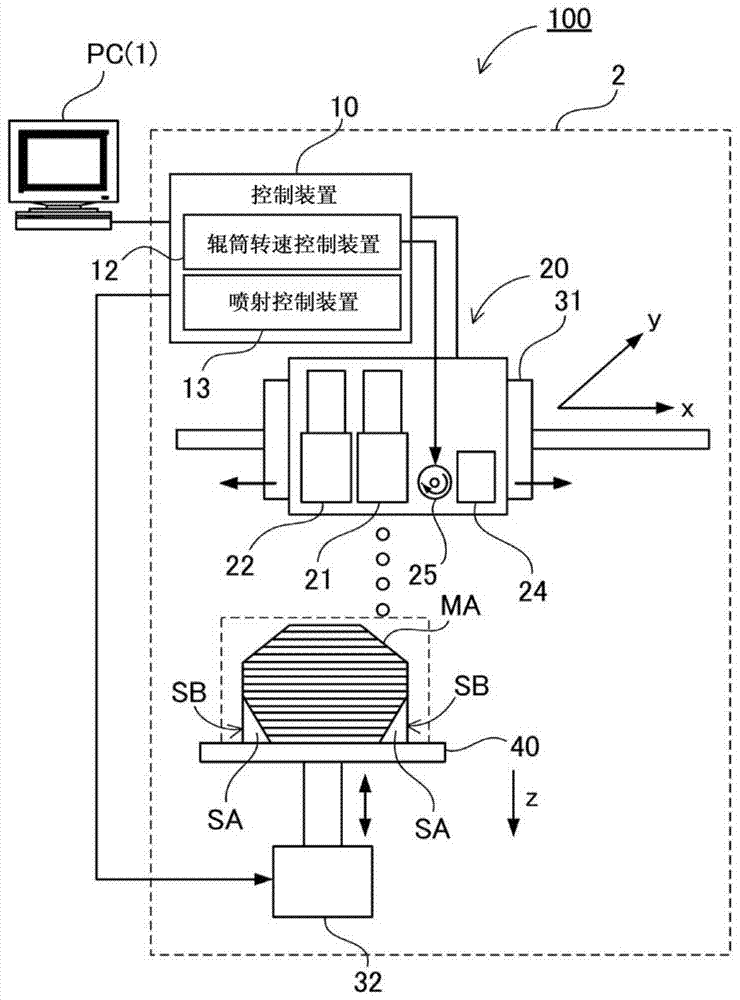

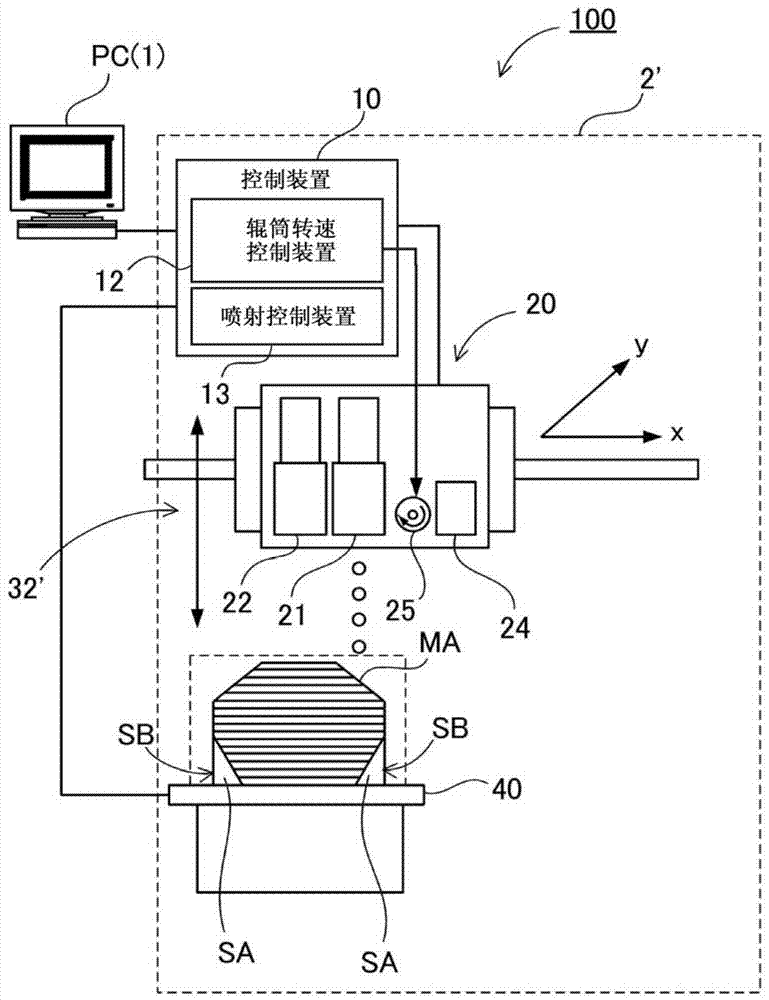

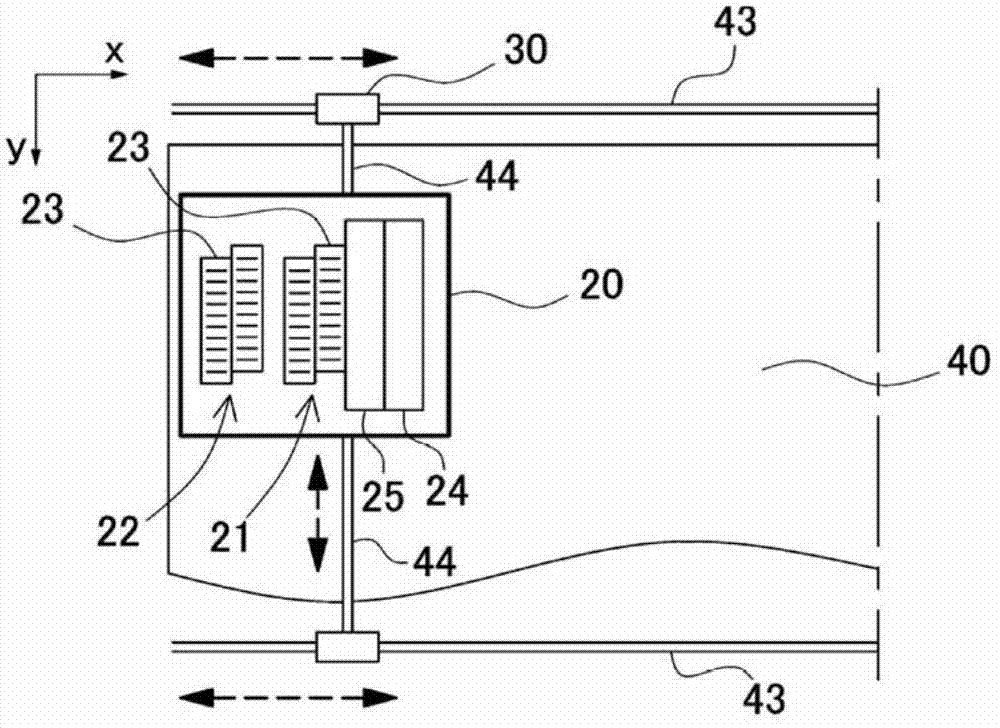

[0080] figure 1 A block diagram of a three-dimensional shaping system 100 according to a first embodiment of the present invention is illustrated. An example in which a three-dimensional forming device is applied in an inkjet method is explained as an example of a three-dimensional forming device. The three-dimensional forming system 100 is suitable for jetting liquid forming materials in an inkjet manner, and then solidifying and stacking these materials to manufacture arbitrary shaped objects. A model material MA and a support material SA are used as the forming material, wherein the model material MA is configured to form a final shaped object, and the support material SA is configured to be formed to support a protruding portion of the model material MA and finally removed.

[0081] figure 1 The three-dimensional forming system 100 shown is composed of a three-dimensional forming device 2 and a setting data creation device 1 ( figure 1 The computer PC in ), the setti...

Embodiment 1

[0154] (Example 1: When molding MS at the same time)

[0155] First, an example of simultaneous molding of a mold material MA and a support material SA as a first embodiment will be described. When using simultaneous forming, the model material MA and support material SA are injected in a single pass of the head. Figure 14 Data processing is performed on the forming object data as shown in (a), and follows Figure 14 The sequence shown in (b) shapes the individual layers (slices S1 to S6). In this example, it is assumed that the individual layers are formed in a single slice portion by a single reciprocating motion of the head.

[0156] In traditional simultaneous forming, according to Figure 14 The order shown in (a) sequentially stacks the model material MA and support material SA for each slice. Specifically, a block B1 of support material SA is jetted and cured in slice S1, and after forming the support material layer (block B1), the support material layer (block B2)...

Embodiment 2

[0161] (Example 2: MS independent forming)

[0162] An example of simultaneous forming in which a model material and a support material are simultaneously formed has been described above, but the present invention is not limited in this respect, and the present invention can also be applied to independent forming in which a model material and a support material are separately formed. Independent shaping is used in the second embodiment below, and reference is made to Figure 18 to Figure 21 Describes the stacking sequence of forming materials in independent forming. Use independent forming to form model material MA and support material SA, for Figure 21 Perform data processing on the shaped data shown in (a) to follow Figure 21 (b) Sequential shaping of each layer (slices S1 to S6) shown. In this example, it is assumed that the individual layers are formed in a single slice portion by a single reciprocating motion of the head.

[0163] In the usual independent forming, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com