Spraying component of large-scale three-dimensional transfer printing machine

A transfer printing machine, three-dimensional technology, applied in rotary printing presses, printing presses, transfer printing and other directions, can solve the problems of waste, difficult nozzle adjustment and maintenance, uneven spraying of activators, etc., to save maintenance work time, uniform spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the detailed description is as follows with the preferred embodiment shown in the accompanying drawings:

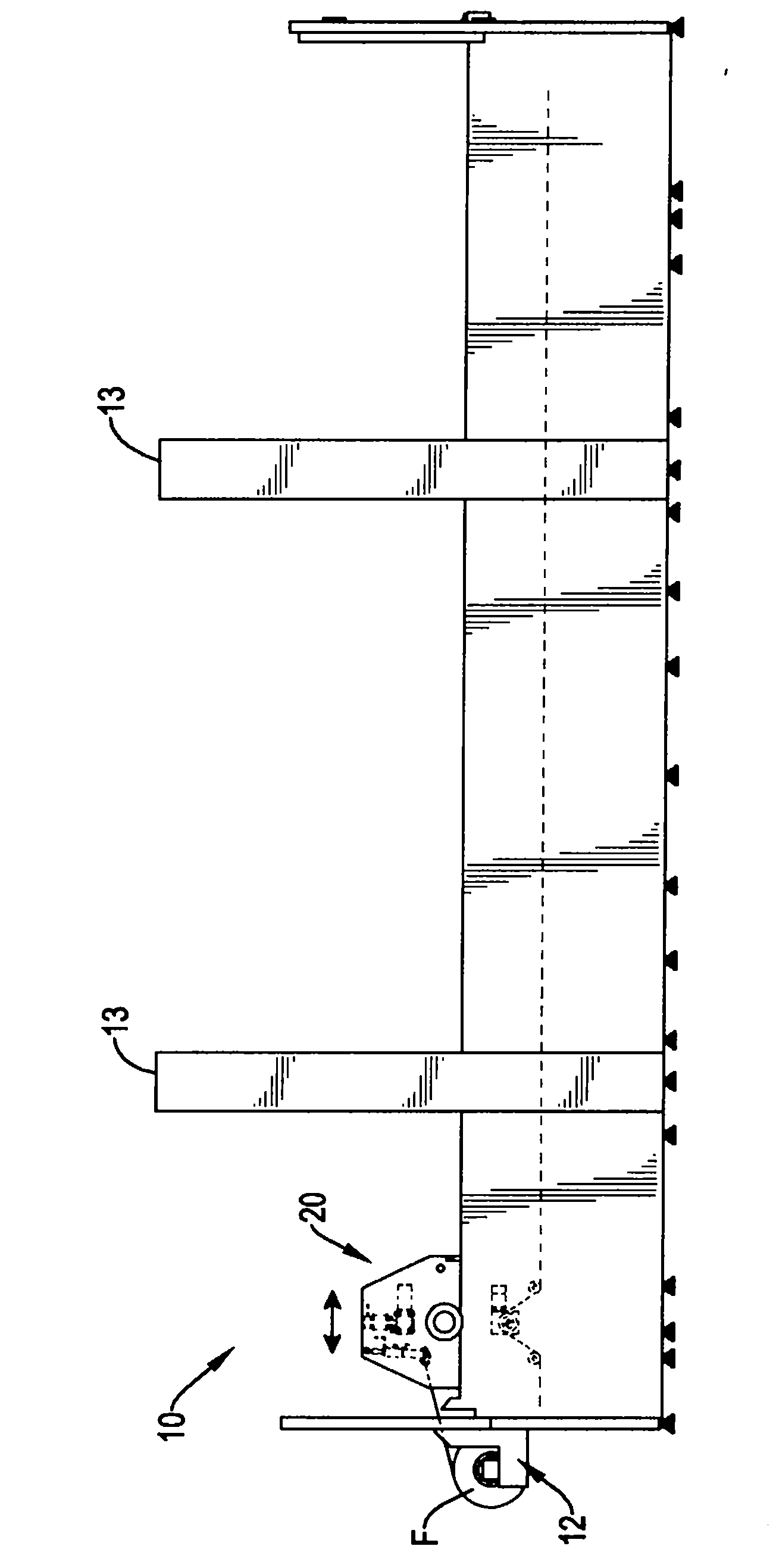

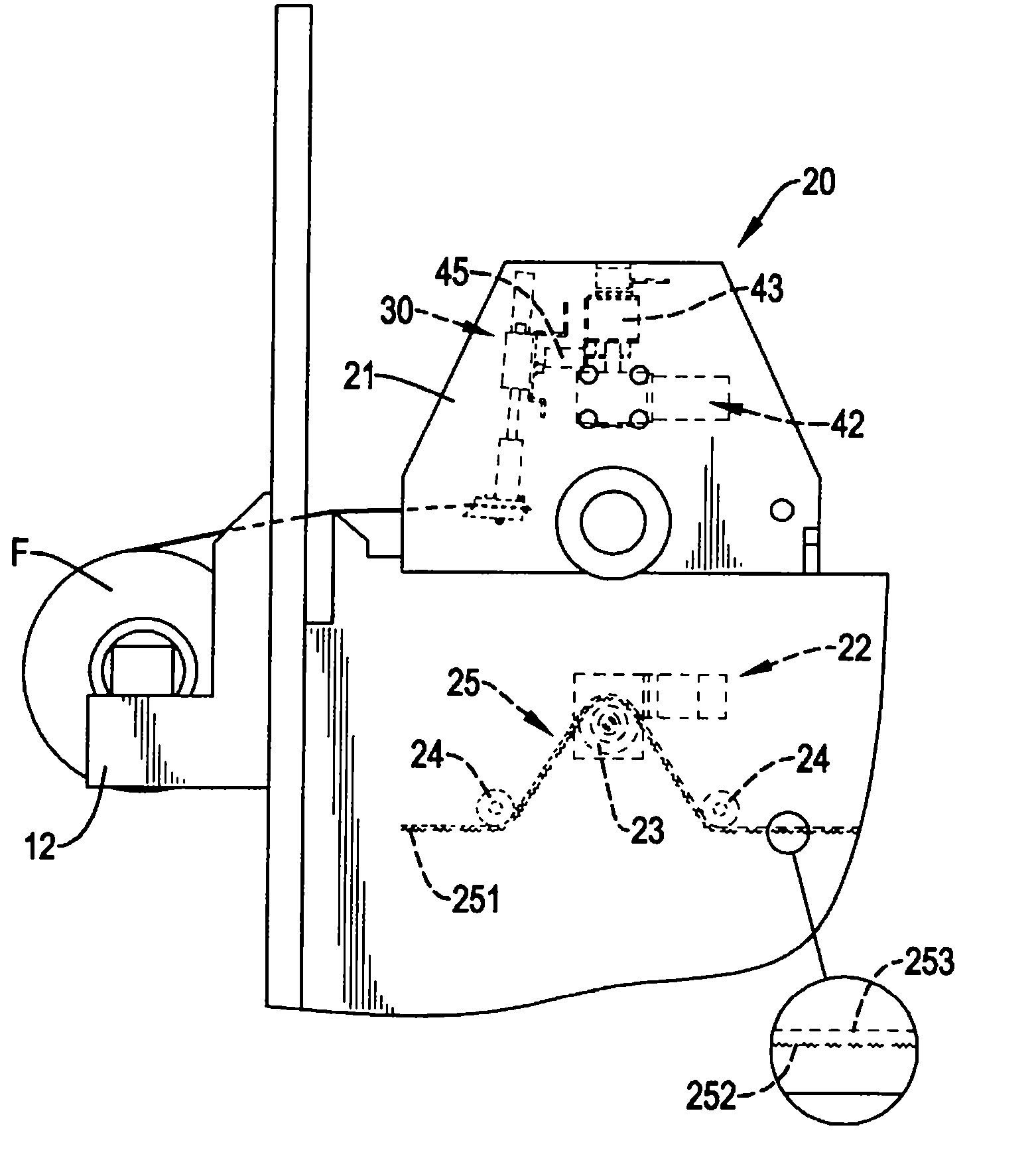

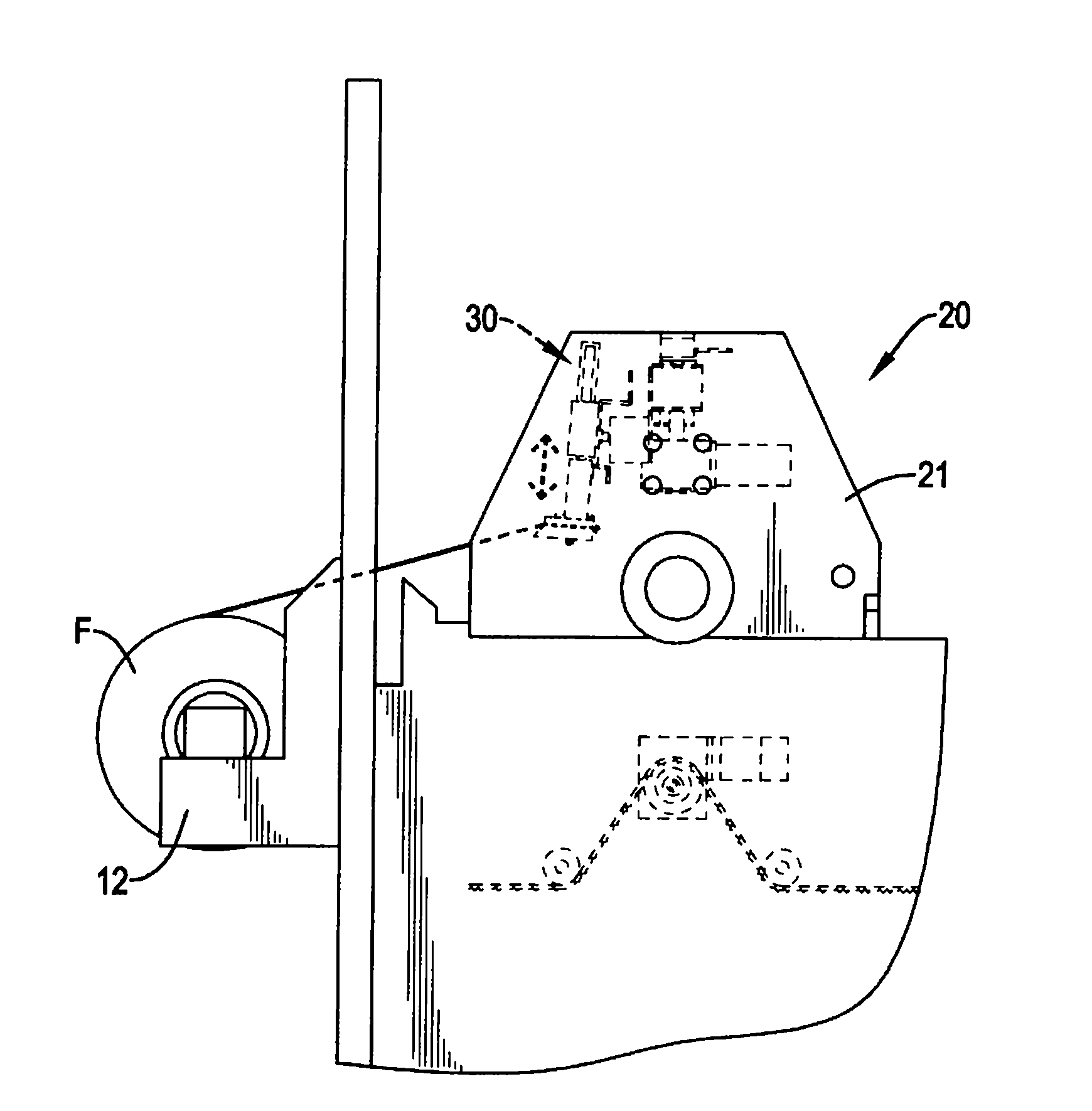

[0042] A preferred embodiment after the spray assembly of a large-scale three-dimensional transfer printing machine provided by the present invention is combined with a body 10 and a film holding device 30, as figure 1 As shown, including: a transmission device 20 and a nozzle device 40 and other components, wherein:

[0043] Such as figure 1 and Figure 7 As shown, the body 10 forms a water tank 11 on a top surface and is provided with a film roll positioning seat 12 on one side in the length direction of the body 10; a film roll F is rotatably combined with the film roll positioning seat 12; The machine body 10 is provided with two upright stands 13 on one side, and the two stands 13 can posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com