Construction method of cast-in-place concrete crash barrier with eaves

A technology of anti-collision guardrail and construction method, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of high labor input, slow progress, insecure safety, etc., and achieves low investment cost of formwork and construction safety. High and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

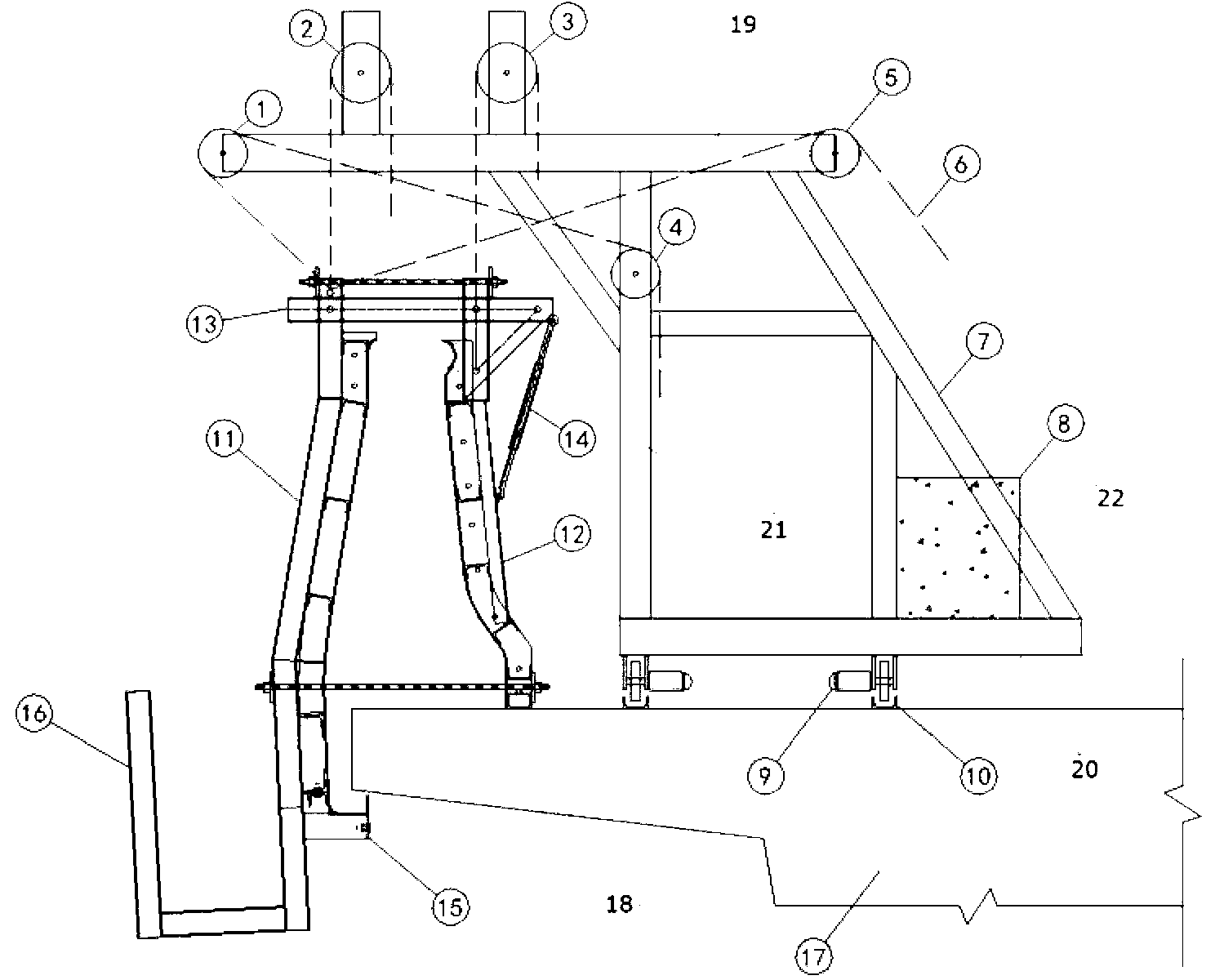

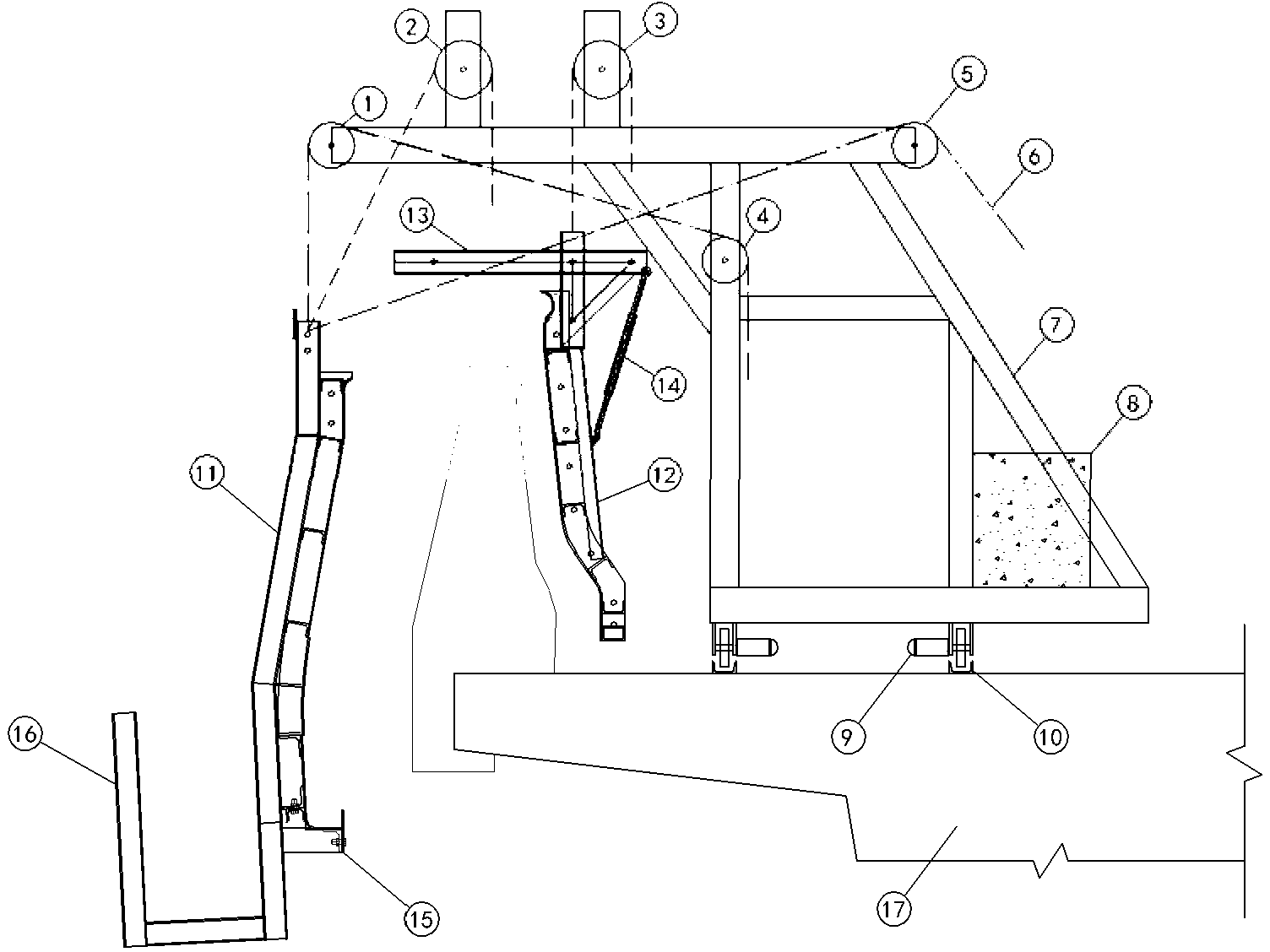

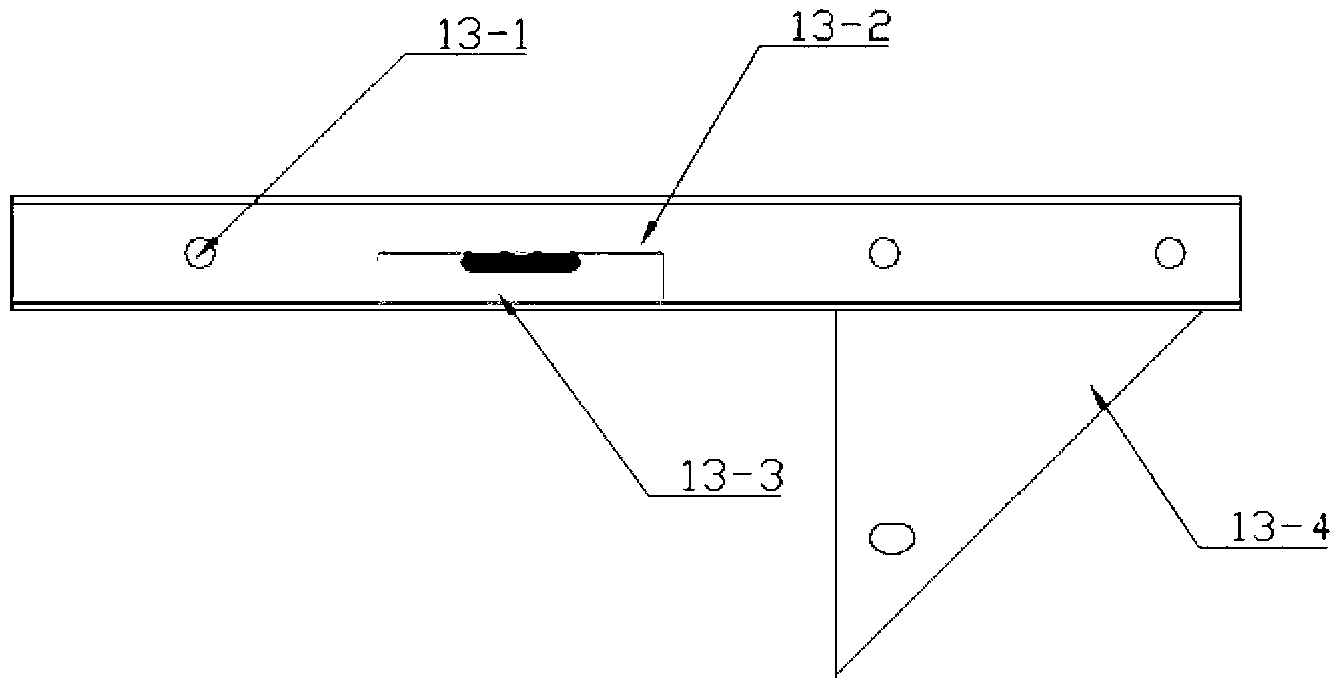

[0022] Such as figure 1 As shown, a movable construction device with cast-in-place concrete anti-collision barriers with hanging eaves includes a trolley and an integral formwork. , 4, 5). Wherein, the transverse structure of vehicle frame 7 is connected by bolts by adopting standard section channel steel by crossbeam 19, bottom beam 20, vertical beam 21 and cable-stayed beam 22. The fixed pulleys 1 and 5 in the pulley block are respectively arranged at the two ends of the crossbeam; the fixed pulleys 2 and 3 in the pulley block are arranged above the crossbeam, and the fixed pulley 4 is arranged on the vertical beam below the joint between the vertical beam and the crossbeam. Wire rope 6 is connected with formwork by regulating pulley block. Wherein, the first steel wire rope connects the outer template 11 through the fixed pulley 2 to adjust its vertical position, the second steel wire rope connects the inner template 12 through the fixed pulley 3 to adjust its vertical po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com