Centrifugal impeller flow passage design method for controlling curvature distribution

A technology of centrifugal impeller and design method, applied in mechanical equipment, components of pumping device for elastic fluid, non-variable-capacity pump, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a centrifugal impeller flow channel design method for controlling the curvature distribution. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

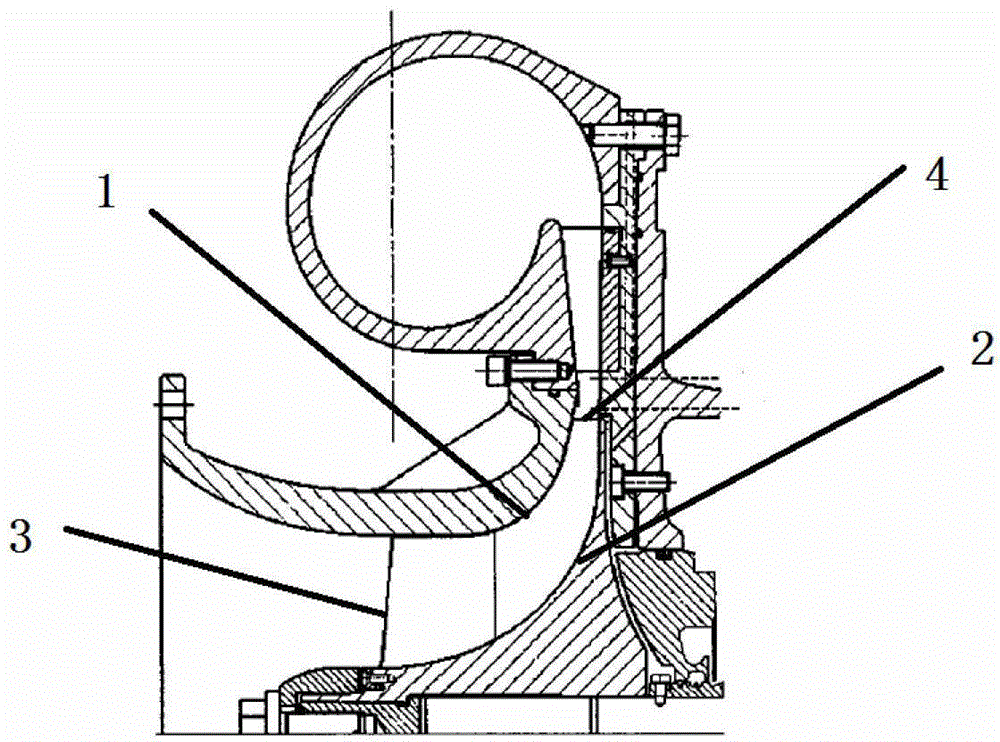

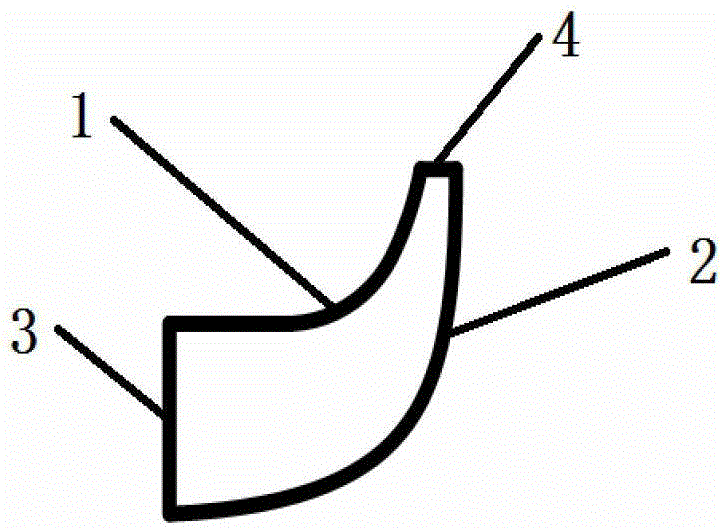

[0023] The axial longitudinal section of centrifugal impeller machinery is generally called meridian flow channel. The meridian runner is enveloped by wheel cover line 1, hub line 2, inlet line 3 and outlet line 4, as figure 1 and figure 2 shown.

[0024] The design steps of the meridian flow channel are:

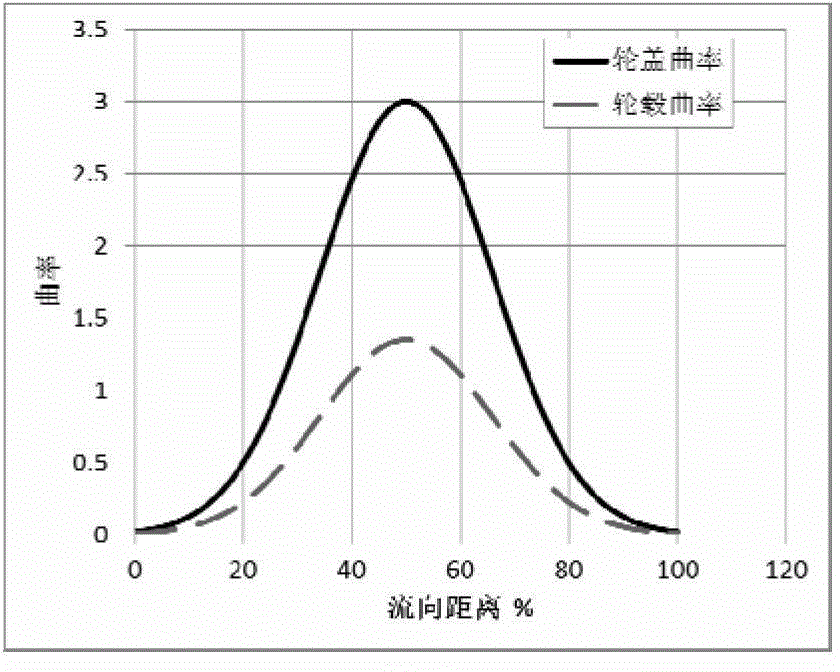

[0025] (1) According to the formula Determine the curvature distribution curve of the wheel cover line, take μ=0.5, A=0.03, m is in the interval [0,1], and e is a natural constant 2.718, so the distribution curve of C is obtained as image 3 The center wheel cover curvature is shown.

[0026] (101) Take n=100 points on the curvature distribution line as the curvature values required for determining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com