Centrifugal impeller flow passage design method for controlling slope distribution

A technology of centrifugal impeller and design method, applied in mechanical equipment, components of pumping device for elastic fluid, non-variable-capacity pump, etc. Improve functional work efficiency, good flow performance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a centrifugal impeller flow path design method for controlling slope distribution. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

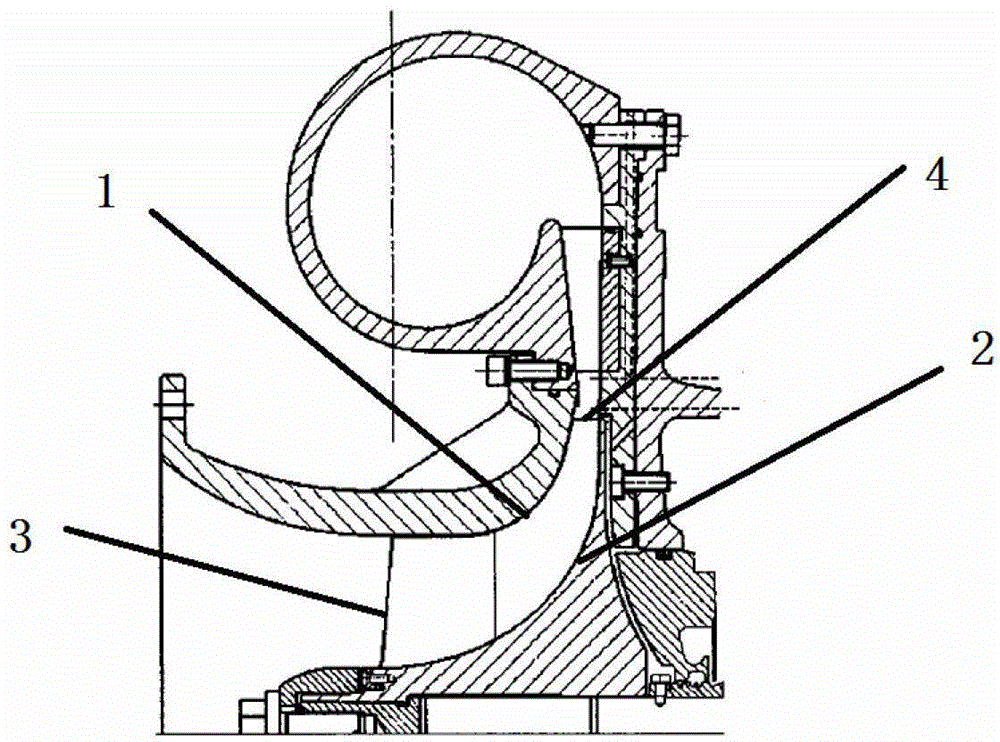

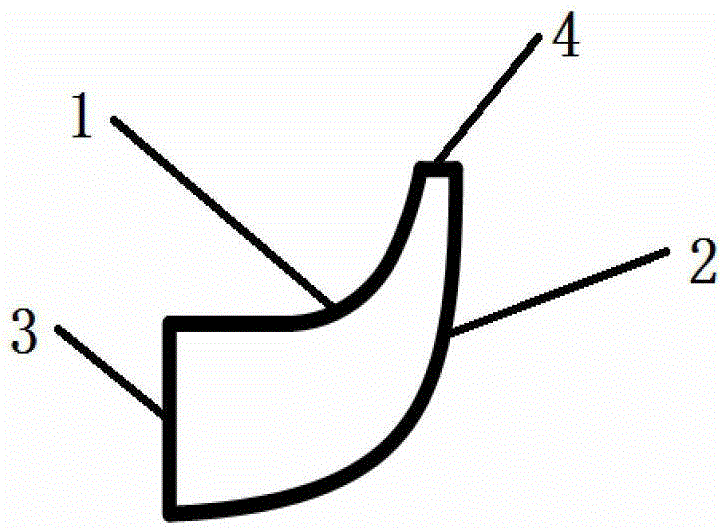

[0023] The axial longitudinal section of centrifugal impeller machinery is generally called meridian flow channel. The meridian runner is enveloped by wheel cover line 1, hub line 2, inlet line 3 and outlet line 4, as figure 1 with figure 2 shown.

[0024] The design steps of the meridian flow channel are:

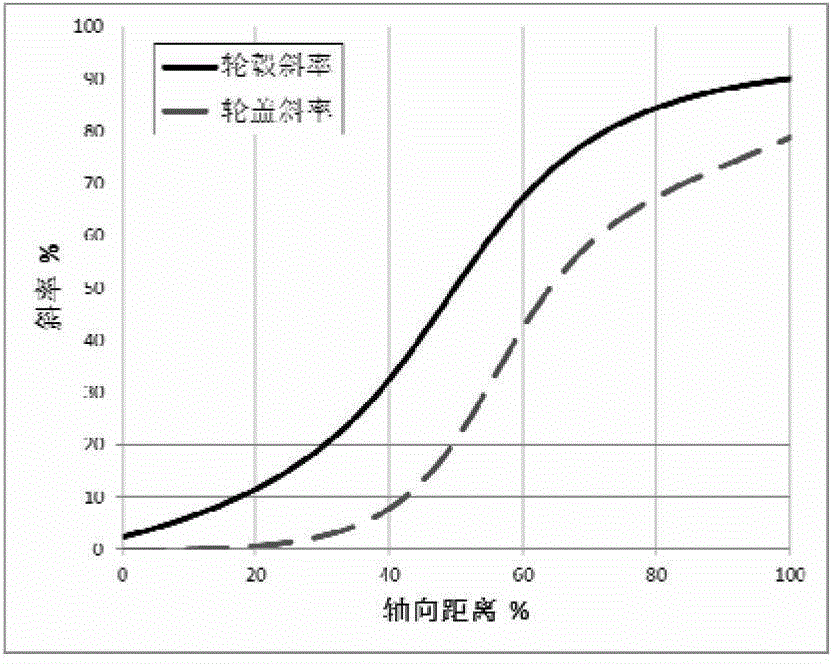

[0025] (1) The slope distribution law of the wheel cover line and the hub line, using the cubic polynomial S(x)=Ax 3 +Bx 2 +Cx+D to determine, where S is the slope of the curve, x is the length of the dimensionless flow direction, A, B, C, and D are dimensionless coefficients, and the specific values are shown in the following table:

[0026]

A

B

C

D

wheel cover line

3e-4

4.0e-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com