Hinge pin for full-bushing full-slewing drilling machine

A technology of full rotary drilling rig and full casing, which is applied in mechanical equipment, pivot connections, engine components, etc., can solve the problems of backward lubrication method, difficult construction, and shorten the service life of pins, and achieves obvious lubrication effect and high work efficiency. , use reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

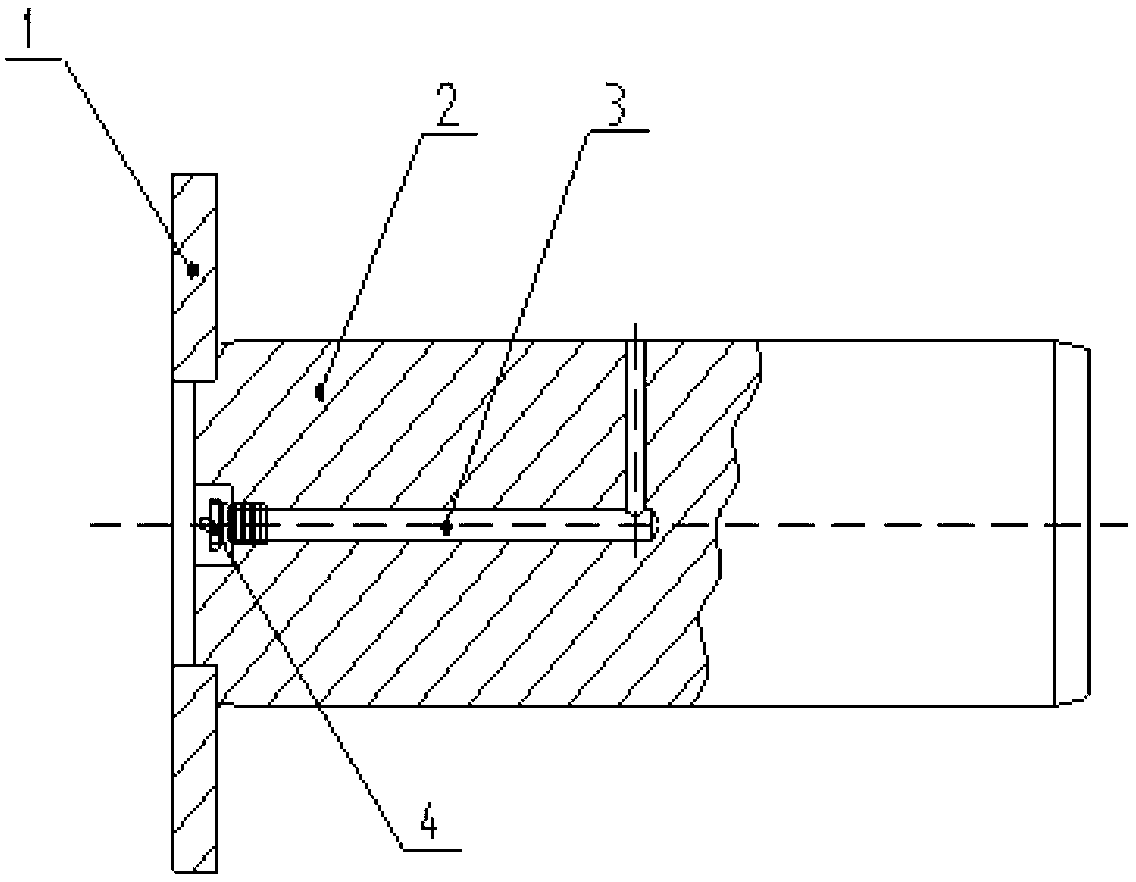

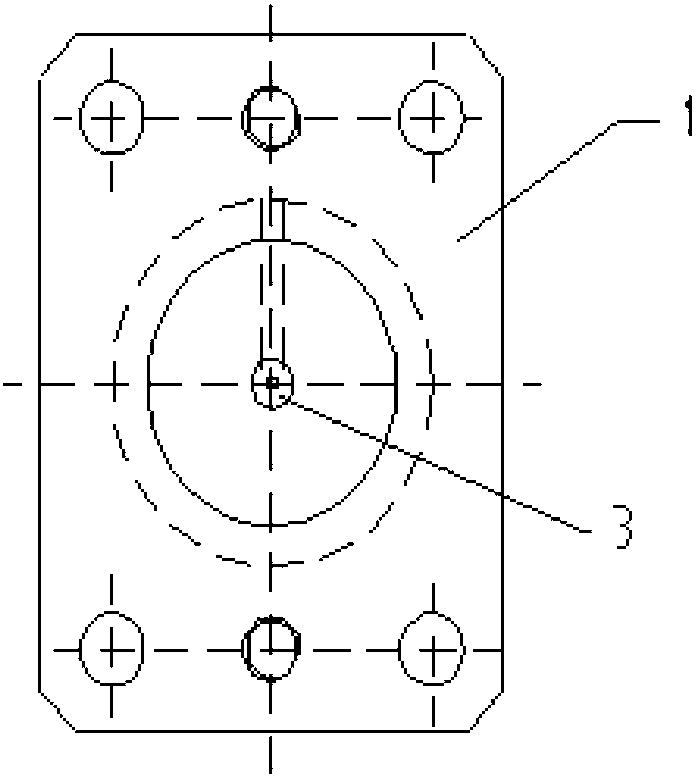

[0015] A pin shaft for a full-casing full-rotation drilling rig includes a flange 1, a shaft body 2, lubricating holes (3, 4), and a grease nipple 5. The flange 1 and the shaft body 2 are welded, and then connected to the oil cylinder through the hole on the flange 1, the lubricating hole 3 and the lubricating hole 4 penetrate each other, and the lubricating tool adds lubricant to the shaft through the grease nipple 5 to lubricate The material reaches the surface of the shaft 2 through the lubricating hole 3 and the lubricating hole 4, thereby lubricating the shaft 2 and connecting the oil cylinder.

[0016] In order to further improve the lubricating effect, the number of lubricating holes can be two, three or more. When there are two lubricating holes, the two lubricating holes are arranged symmetrically on the shaft body. When there are three lubricating holes, the three lubricating holes can be located on the same circumferential surface and distributed evenly, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com