Method for improving stability of alignment precision of high-transparency mask plate

A technology with high light transmittance and overlay accuracy, which is applied in the field of semiconductor manufacturing, can solve the problems affecting the production efficiency of lithography process, the offset of registration accuracy, and the decrease of wafer yield rate, so as to improve the yield rate and process production Efficiency, reducing the degree of thermal expansion of the lens, and maintaining stable overlay accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for improving the accuracy and stability of overetching of a mask with high light transmittance proposed by the present invention will be described in further detail below with reference to specific embodiments. The advantages and features of the present invention will become apparent from the following description and claims.

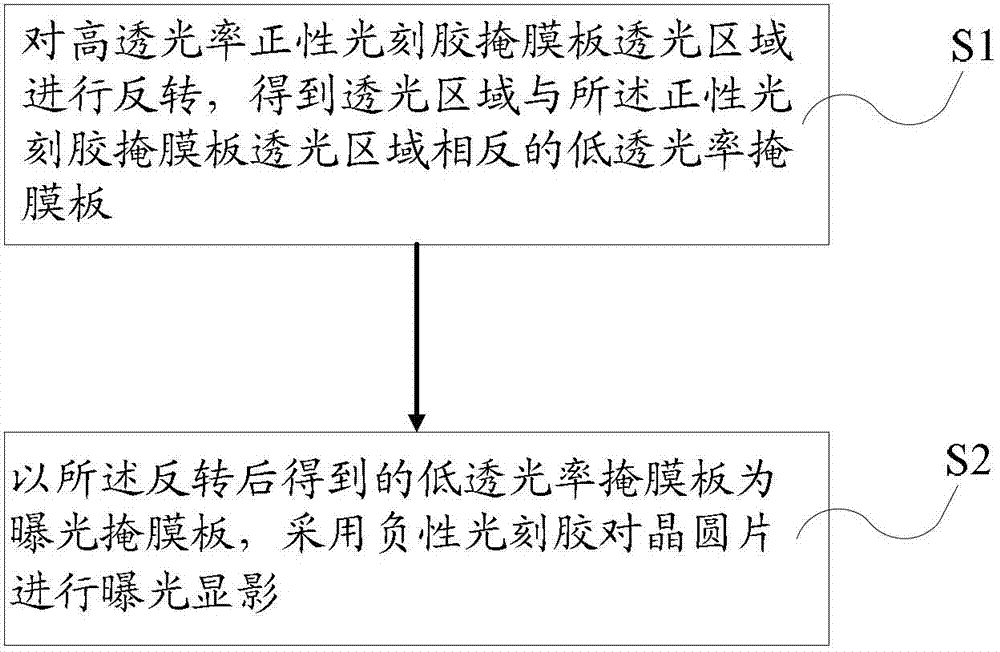

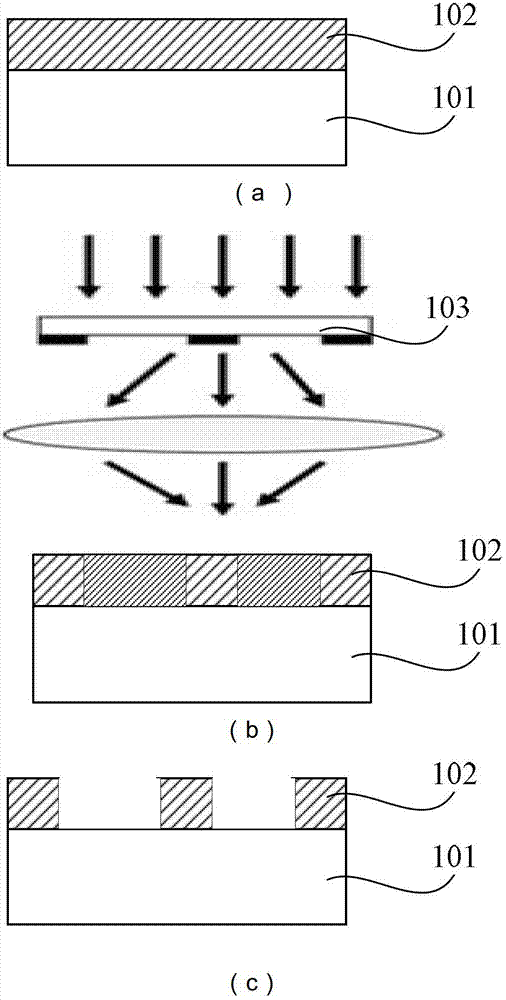

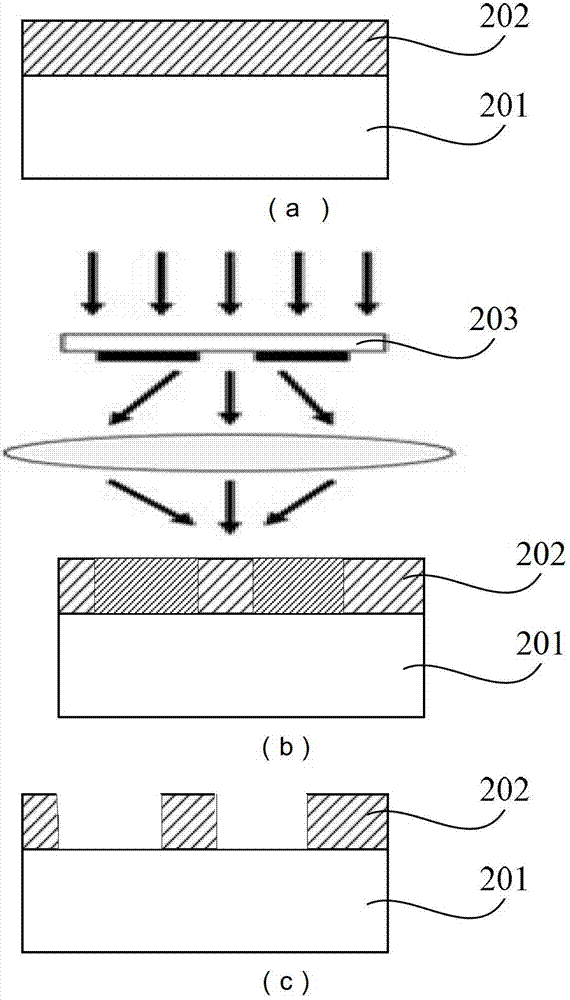

[0020] The core idea of the present invention is to provide a method for improving the accuracy and stability of the overlay of the high-transmittance mask plate. A low-light-transmittance mask with a light-transmitting region opposite to the light-transmitting region of the positive photoresist mask, and then using the low-light-transmittance mask obtained after the reversal as an exposure mask, using The negative photoresist exposes and develops the wafer, which effectively reduces the energy of the lens heating during the exposure process, and reduces the degree of thermal expansion of the lens after the continuous exposure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com