Point-by-point correcting equipment and correcting method thereof for LED (Light-Emitting Diode) display screen in simulation field

A LED display, point-by-point correction technology, applied to static indicators, instruments, etc., can solve the problems of a large amount of manpower, material resources and time, low correction efficiency, low economic benefits, etc., to save travel expenses, high correction efficiency, Effect of Correction Difficulty Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

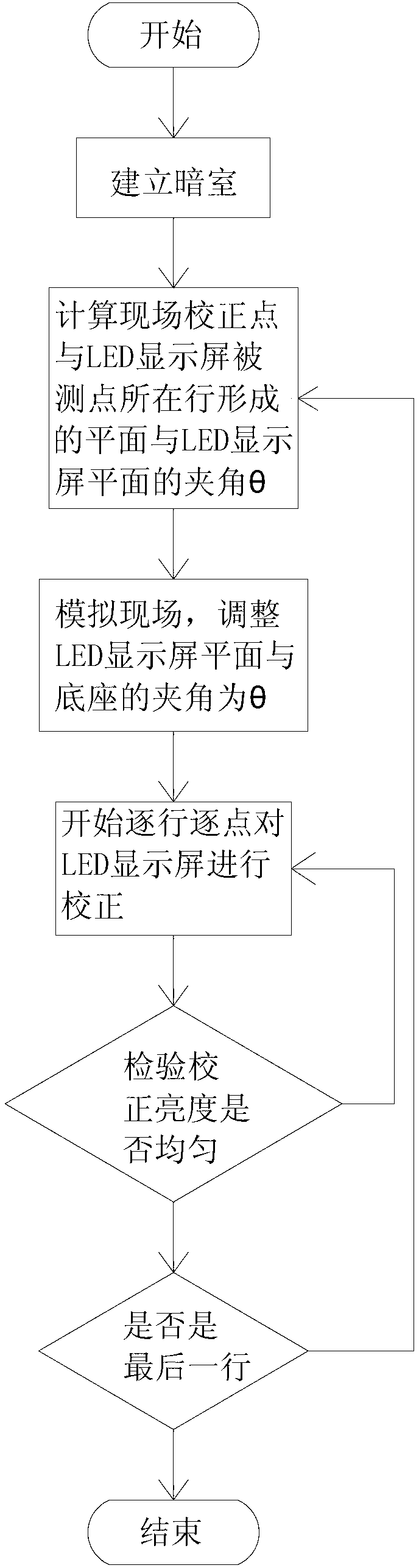

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

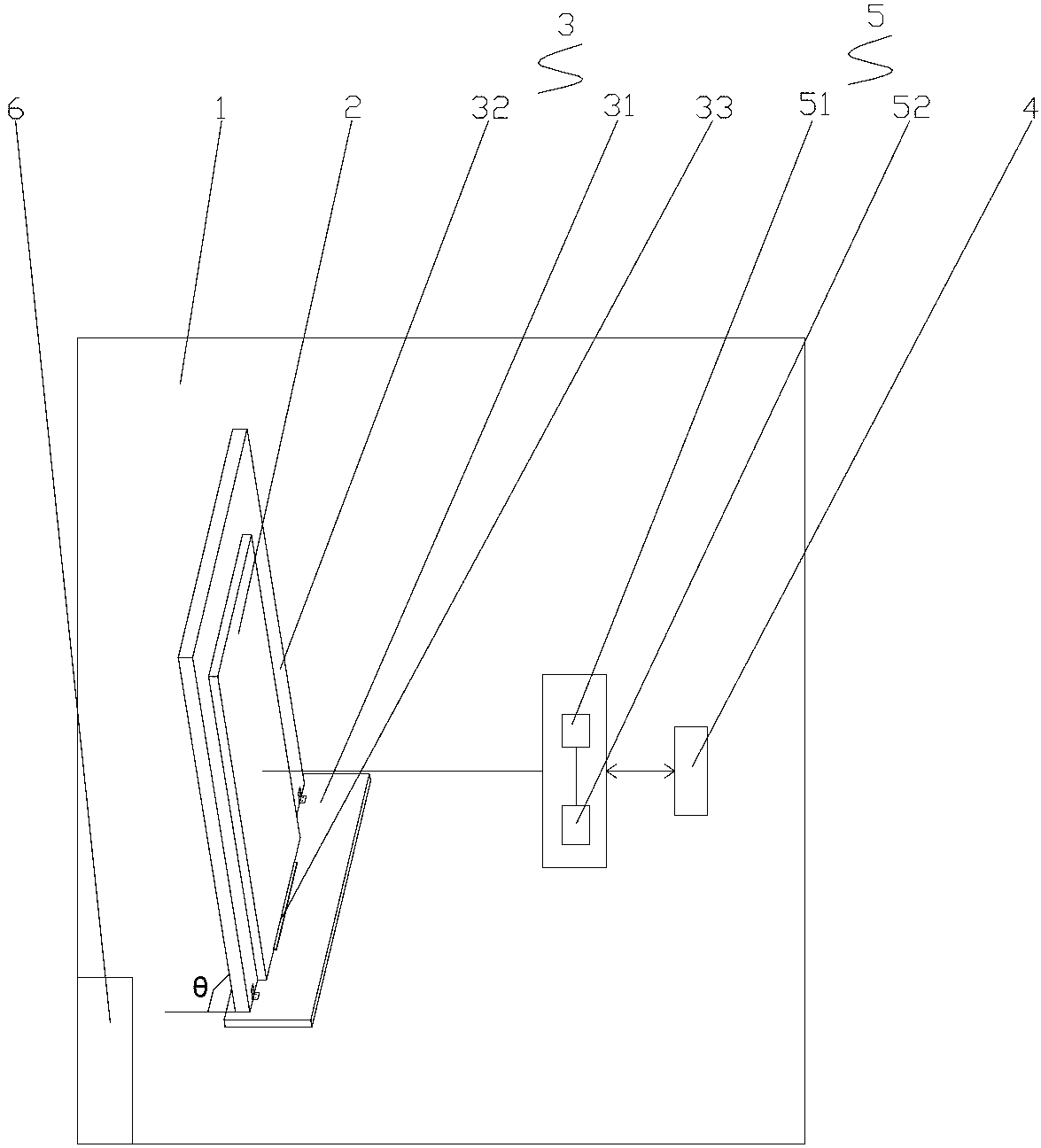

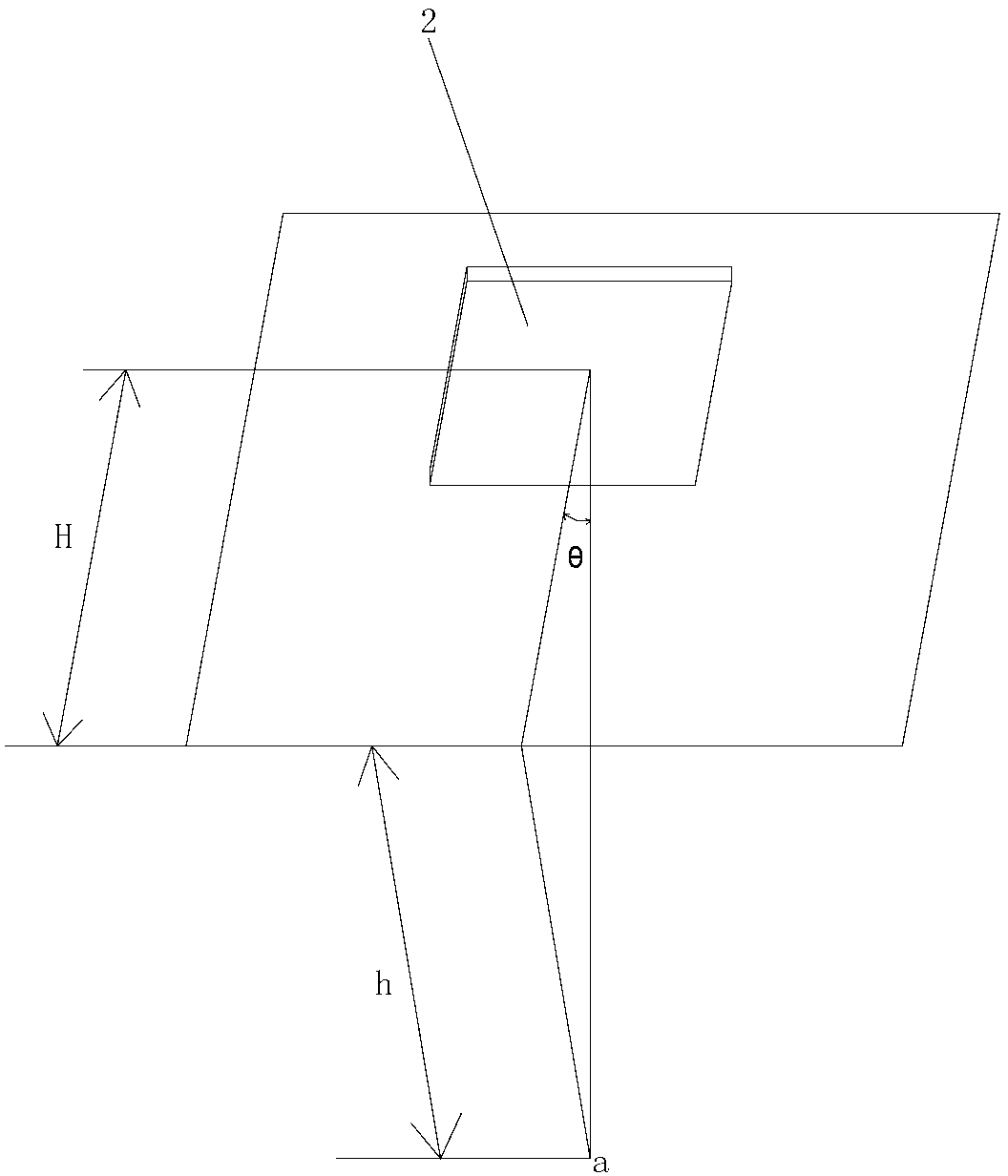

[0028] Such as figure 1 or figure 2 As shown, the present invention is a point-by-point correction device for LED display screens simulating the scene. The correction device includes a darkroom 1, and an LED display screen 2, a display screen correction frame 3, an LED control system 4 and a correction device installed in the dark room 1. The device 5 and the LED control system 4 are electrically connected to the LED display screen 2 and the calibration device 5 respectively. greater than 15m;

[0029] The display screen correction frame 3 includes a base 31 and a support plate 32, the bottom of the support plate 32 is rotationally connected with the base 31, the back of the LED display screen 2 is against the surface of the support plate 32, the bottom of the LED display screen 2 is placed on the base 31, and the LED display screen 2 is placed on the base 31. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com