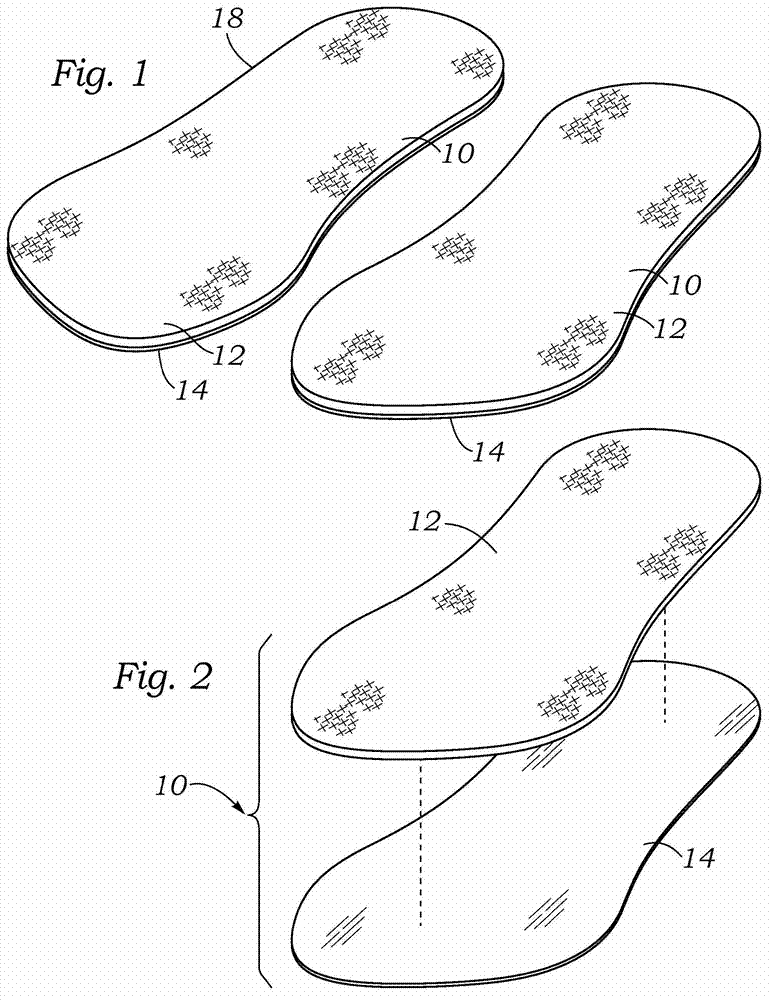

Insole for footwear

A product, footwear technology, applied in the direction of soles, footwear, layered products, etc., can solve problems such as excessive sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

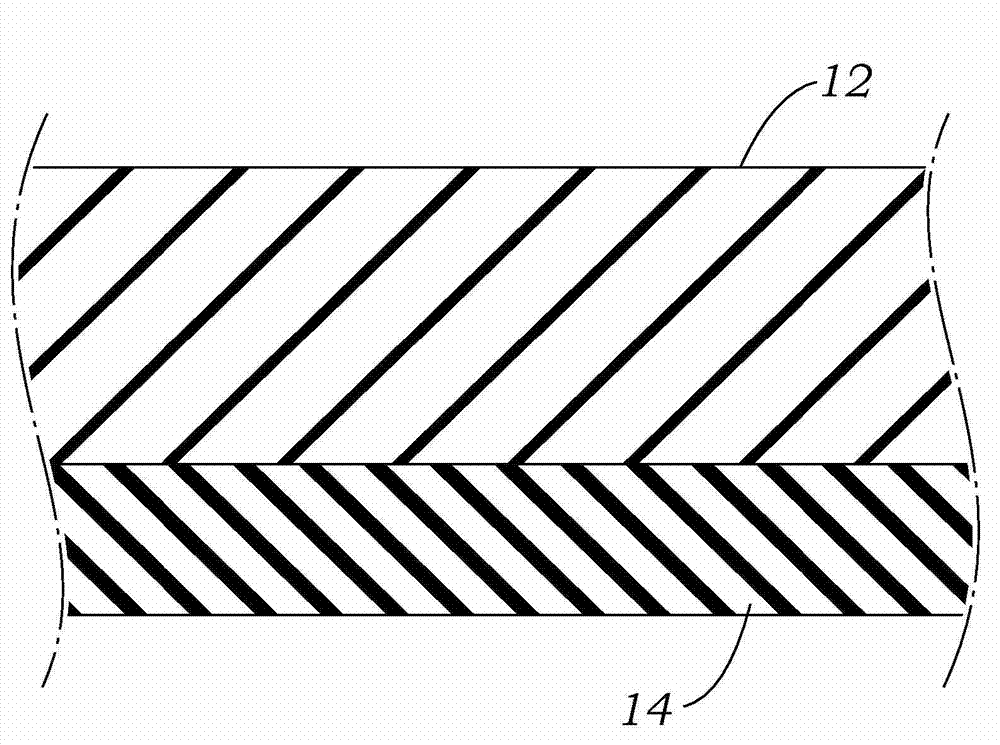

[0066] Several insoles are manufactured by forming a layer of LSR on the following types of fabrics: cotton mesh, 80% wool / 20% polyester blend felt, and Polartec 300 fleece. Shrinkage of the insole was measured using the ISO 3759 standard to prepare marks and measure the dimensional change of the fabric. Shrinkage was induced by four wash-dry cycles loosely guided by ISO 6330 standard Type B (rotary agitator washing machine) and procedure E (tumble dry). The cleaning temperature is from about 64 degrees Celsius to about 66 degrees Celsius. The dry load was approximately 6.7 kg and included three samples of each coated fabric. In addition to the coated material, uncoated control fabrics were washed and dried in the same batch. The coated fabric is limited to limited dimensional changes through successive aggressive washing and drying cycles. The average shrinkage for each type of coated and uncoated fabric is shown in FIG. 9 . As shown, the coated material was limited to ...

Embodiment 2

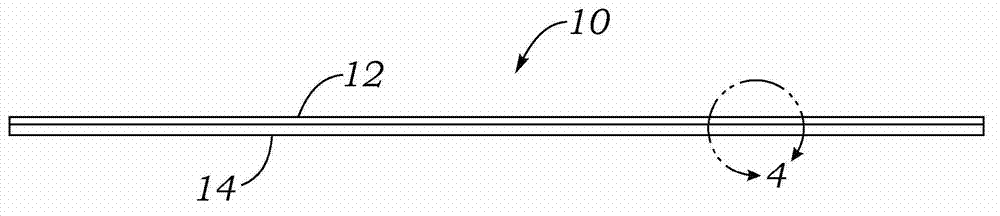

[0068] A variety of standards can be used to quantify the tack value and shear strength of the base layer of the insole, including ASTM D2979, ASTM D1894, and ASTM D3654 Procedure A (Test Method for Shear Adhesion of Pressure Sensitive Shapes). In some embodiments, the insole has a base layer formed from an LSR having a tack value of about 0.2N to about 2.2N, more desirably between about 1N and about 2N, as measured according to ASTM D2979 .

[0069] According to ASTM D1894, the shear strength of a material is defined as equal to the ratio of the tensile force applied to the test material to the total weight falling on top of the test material. In some embodiments, the insole has a base layer formed from LSR having a ratio in the range between about 2 and about 24.

[0070] ASTM D3654 Procedure A measures the time it takes for a bonded material to separate from another surface under the force of gravity. Insoles with a base layer formed of LSR have no measurable value accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap