Method for detecting damage of bearing

A damage detection and bearing technology, applied to bearings, bearing assembly, bearing components, etc., can solve problems such as difficult characteristic frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

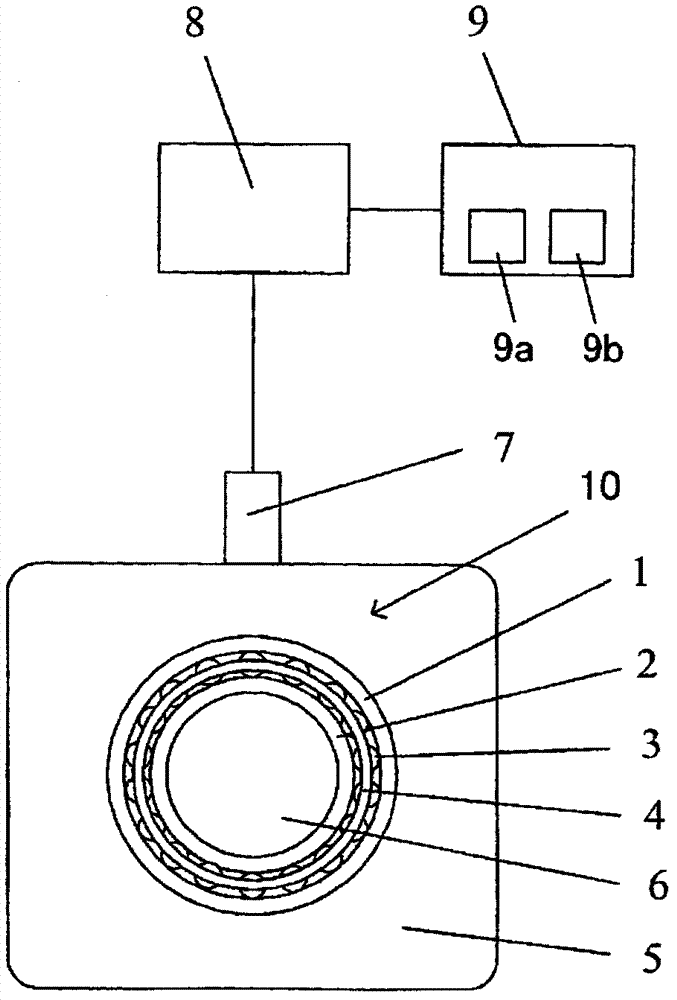

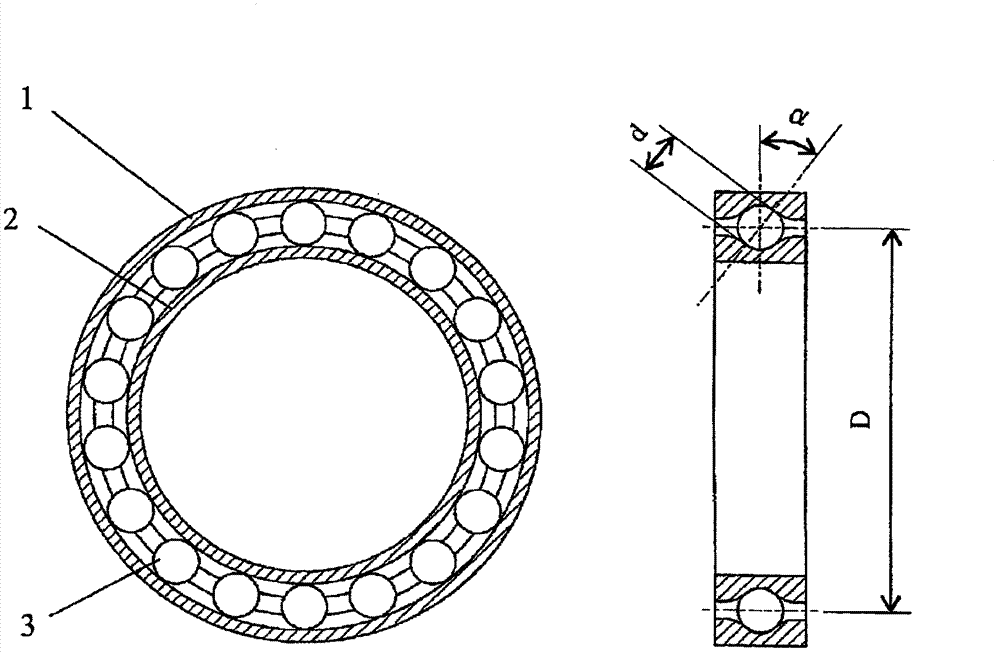

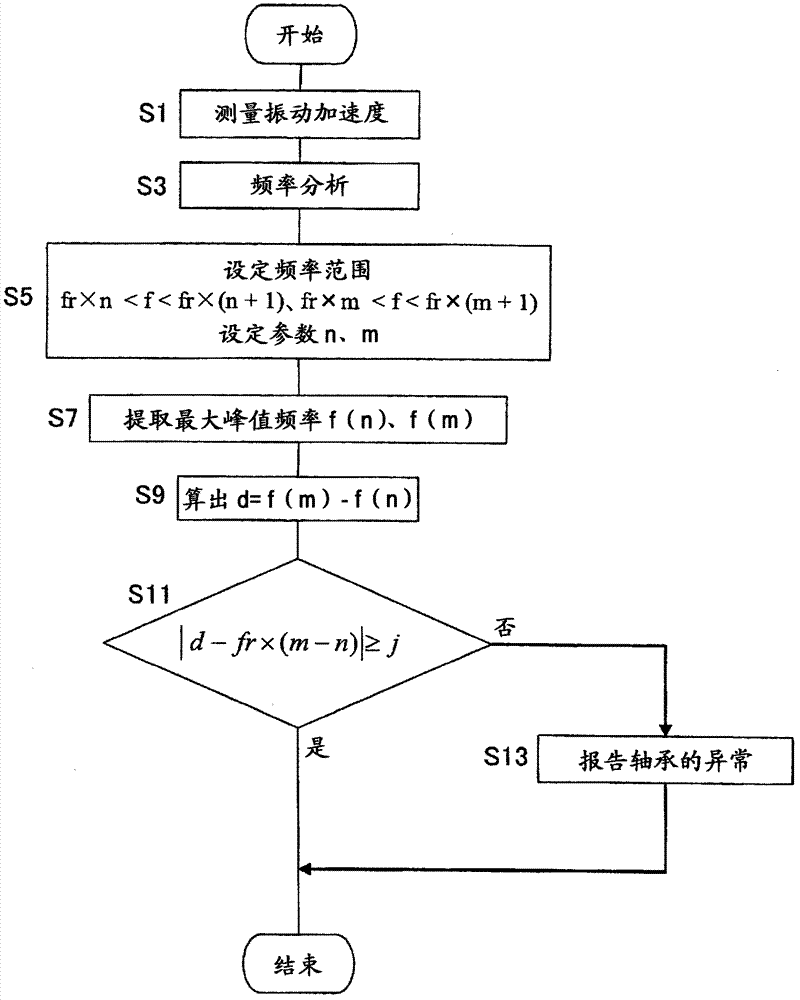

[0028] refer to Figure 1~4 A first embodiment of the bearing damage detection method of the present invention will be described. figure 1 It is a figure showing the structure of the bearing damage detection apparatus based on the bearing damage detection method of this invention, figure 2 It is a sectional view showing the structure of a single row deep groove ball bearing as an example of a radial ball bearing. The bearing damage detection device of this embodiment includes: an acceleration sensor 7 that measures vibration acceleration; an amplifier 8 that amplifies a signal output from the acceleration sensor 7 ; The bearing damage detection device according to this embodiment may be permanently installed on a device having a bearing to be detected for bearing damage, or may be a movable type device capable of detecting damage to bearings respectively installed on a plurality of devices. In the following description, a structure in which a bearing damage detection device...

no. 2 approach

[0052] refer to Figure 5 , 6 A second embodiment of the bearing damage detection method according to the present invention will be described. In the following description, the same reference numerals are attached to the same components as those of the first embodiment, and differences will be mainly described. About the content which is not demonstrated especially, it is the same as 1st Embodiment. The present embodiment differs from the first embodiment mainly in the point of determining whether or not the bearing 10 is damaged based on the number of times described later.

[0053] Figure 5 It is a flowchart showing the processing content of the damage detection of the bearing in the second embodiment. In addition, in the following description, the processing content which detects whether the inner ring 2 is damaged or not is demonstrated as an example. After the unillustrated power switch of the bearing damage detection device is turned on and the start of the bearing...

no. 3 approach

[0070] refer to Figure 7 , 8 A third embodiment of the bearing damage detection method according to the present invention will be described. In the following description, the same reference numerals are assigned to the same components as those of the first and second embodiments, and differences will be mainly described. Points not particularly described are the same as those of the first or second embodiment. In the present embodiment, similar to the second embodiment, whether or not the bearing 10 is damaged is determined based on the order parameter g(u), but it differs from the first and second embodiments mainly in the following point: Whether or not the average value of the amplitude value of the maximum peak frequency f(u) within is changing with time is used to determine whether or not the damage of the bearing 10 is increasing.

[0071] Figure 7 It is a flowchart showing the processing content of the damage detection of the bearing in the third embodiment. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com