Balanceable rotation element

A technology for rotating elements and elements, applied in the field of installing the rotating elements, can solve the problems of increasing the manufacturing cost of the motor, increasing the manufacturing cost of the rotor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

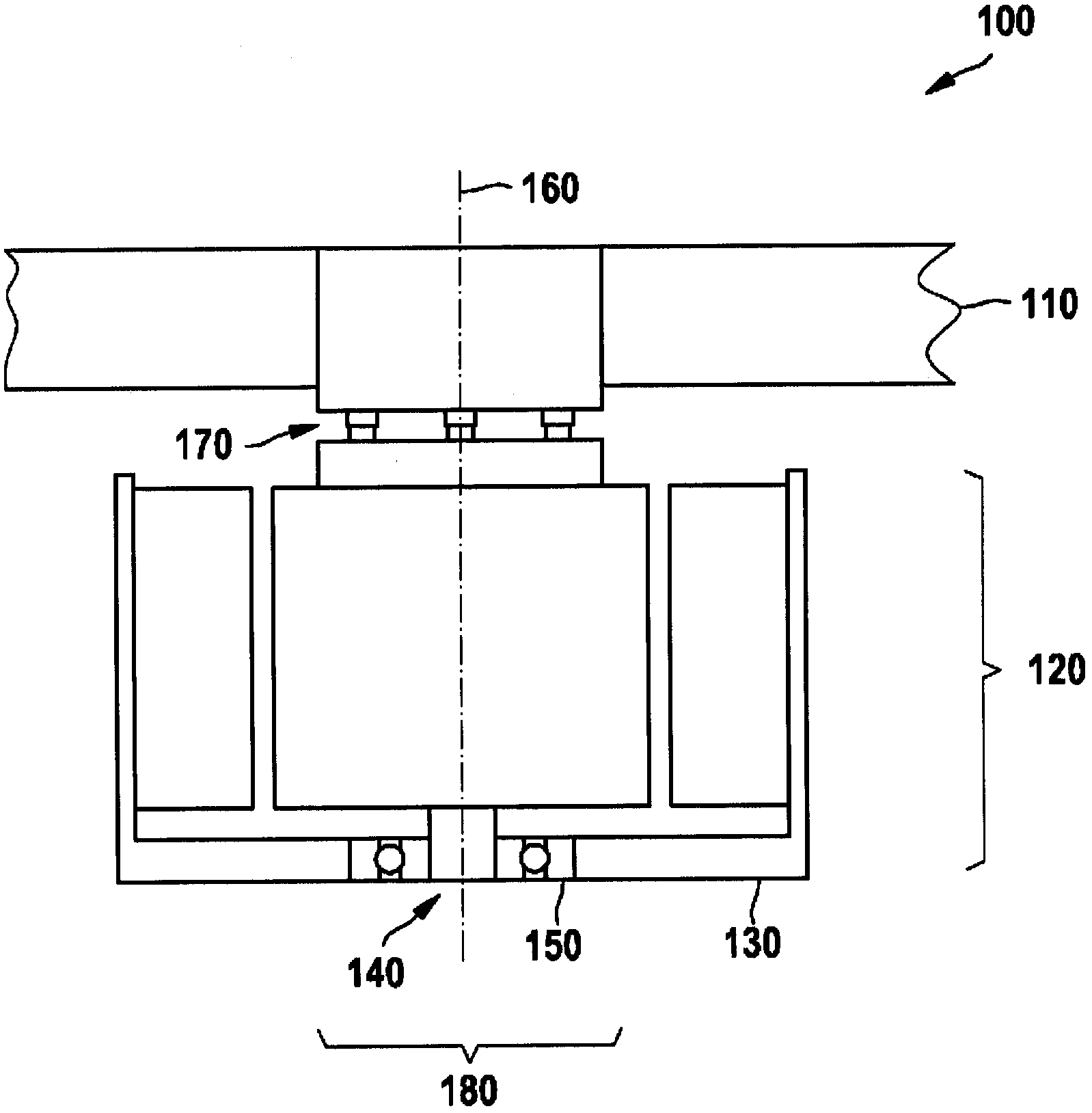

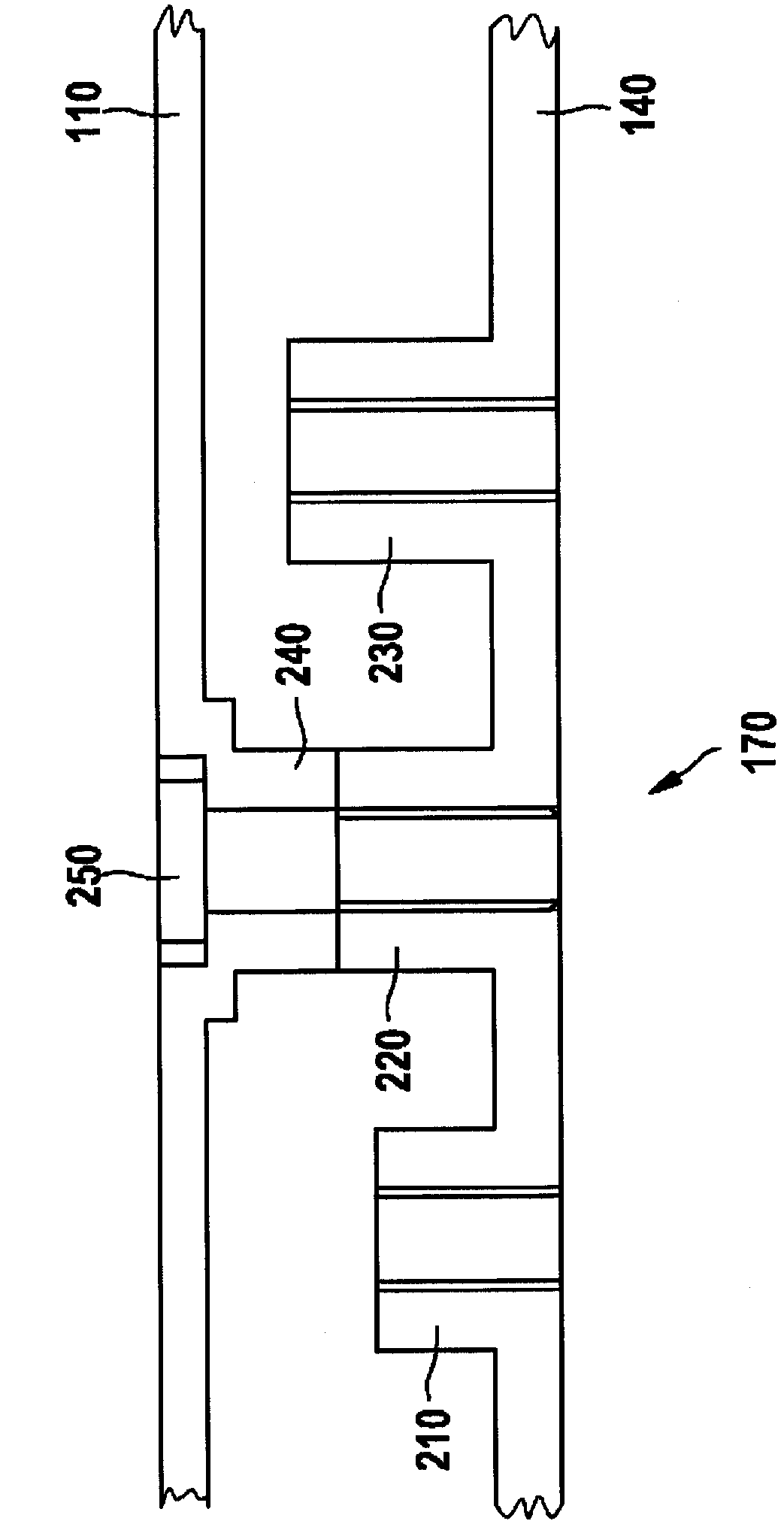

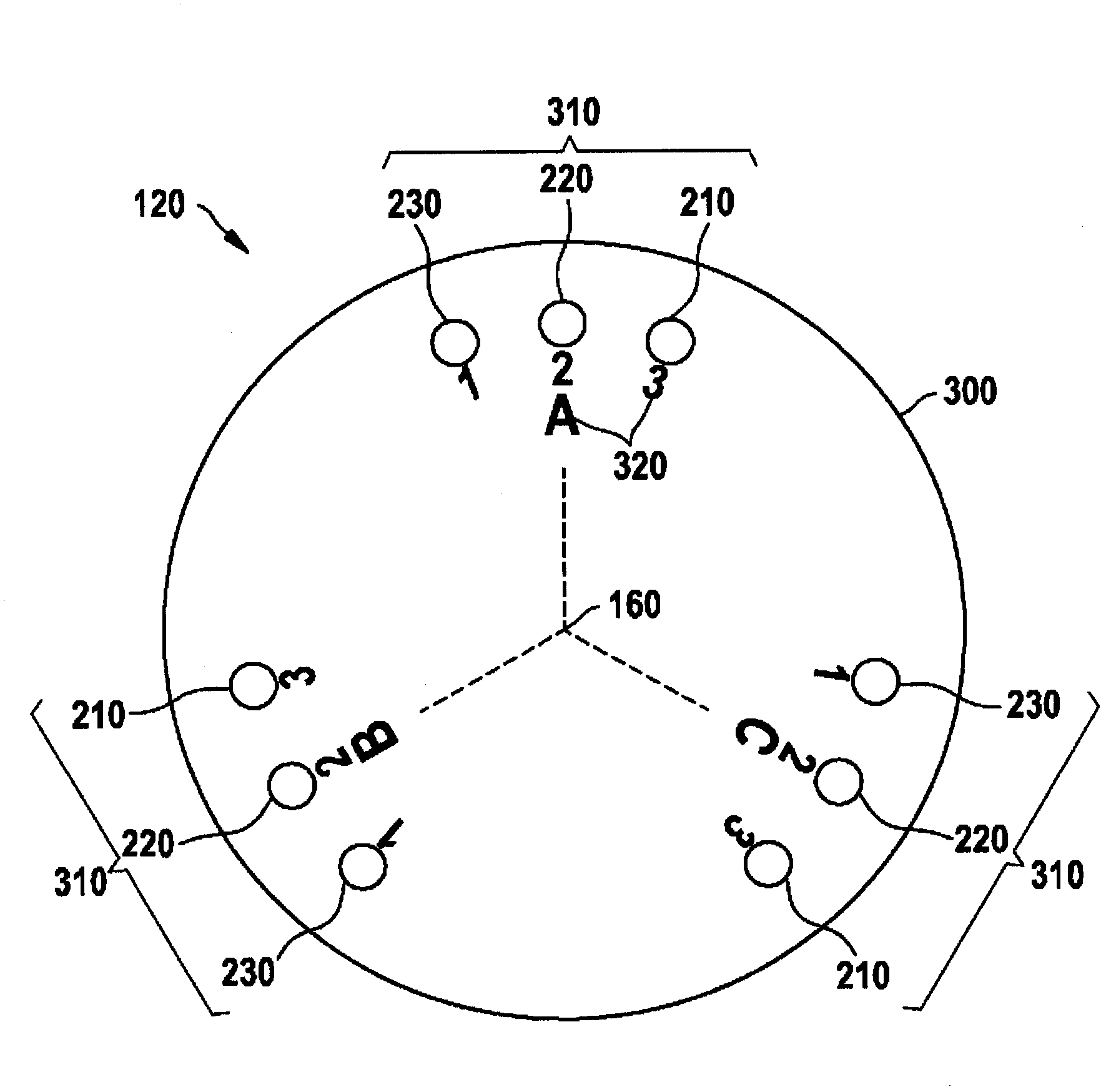

[0020] figure 1 A longitudinal section through an electric motor with a fan wheel is shown. The fan 100 includes a fan wheel 110 and a motor 120 . The electric motor 120 is formed of a stator (fixed member) 130 and a rotor (rotating member) 140 . Bearing 150 connects stator 130 and rotor 140 together such that rotor 140 is mounted rotatably relative to stator 130 about axis of rotation 160 . The fan wheel 110 is connected to the rotor 140 in a torque fit manner by means of a plurality of bearing elements 170 .

[0021] The fan 100 shown is only used as an exemplary embodiment for explaining the invention. The specific design of the fan 100 and in particular of the electric motor 120 should therefore not be included. For example, it is immaterial for the invention whether the electric motor 120 has permanent magnets and whether the permanent magnets are arranged on the stator 130 or on the rotor 140 . The fan wheel 110 is shown only in the region of the electric motor 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com