Simple-to-assemble reusable balancing device and assembling method

A balancing device and simple technology, applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump components, etc. Balance results are affected and other issues, to simplify the rotor balancing process, save the balancing cycle, and improve the rotor balancing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

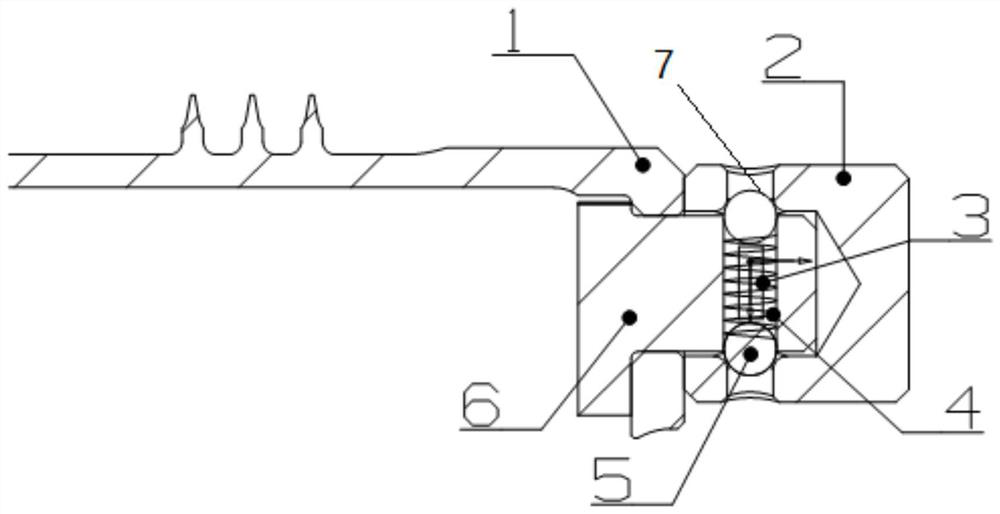

[0028] In this embodiment, figure 1 It is a schematic diagram of the balance device after assembly, such as figure 1 As shown, a reusable balancing device with simple assembly is provided, the balancing device includes a rotor blisk 1 and a balancing weight assembly, and the balancing weight assembly includes a balancing weight cap 2, a spring 3, a limiter 4, and a ball I5 , ball II 7 and balance weight main body 6;

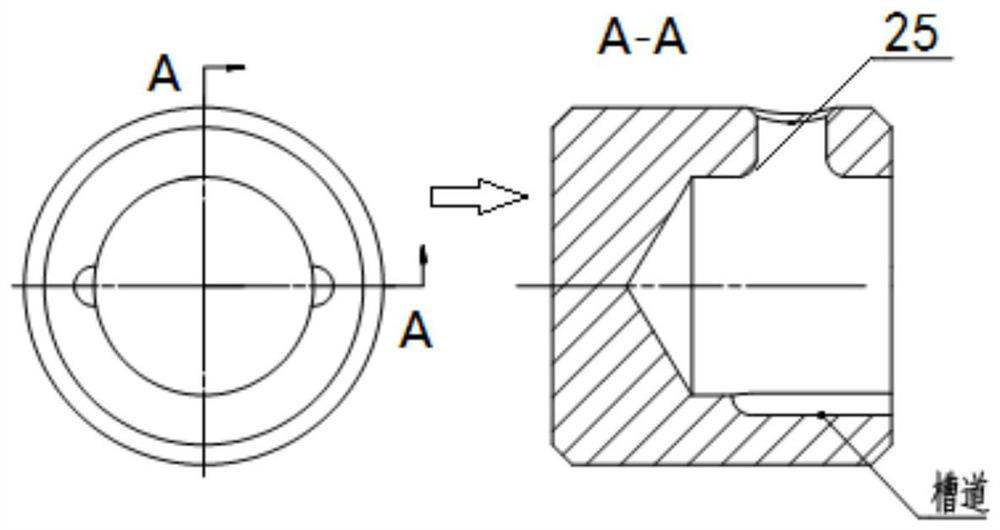

[0029] image 3 It is a schematic diagram of the structure of the balance weight cap, such as image 3 As shown, the balance weight cap 2 is a cylindrical structure with a counterbore, wherein the left figure is a top view, and the right figure is an A-A sectional view. The balance weight cap 2 is provided with a first through hole, and a ball socket is provided at the intersection of the first through hole and the counterbore; the balance weight cap 2 is provided with a channel perpendicular to the direction of the first through hole.

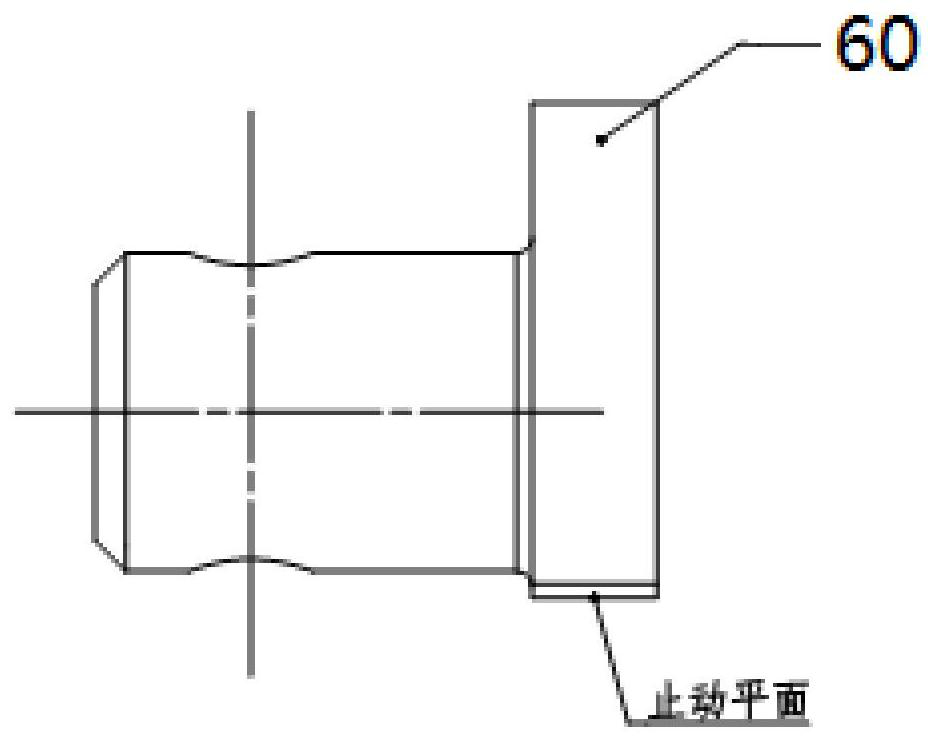

[0030] figure 2 It ...

Embodiment 2

[0036] This embodiment provides an assembly method of a rotor balancing device, using the above-mentioned balancing device, the assembly method includes:

[0037] The fixed end of the balance weight main body 6 passes through the installation through hole of the rotor blisk 1, and the installation end of the balance weight main body 6 is limited to one side of the rotor blisk 1; the spring 3 is arranged in the second through hole, and the ball I5 and the ball II7 Located at both ends of the spring 3 and in the channel;

[0038] Rotate the balance weight cap 2 to make the ball I5 and ball II7 roll from the channel to the ball socket 25, make the spring 3 in a stretched state, and connect the balance weight main body 6 and the balance weight cap 2.

[0039] Further, the stop plane on the mounting end of the balance weight main body 6 is in contact with the rotor blisk 1 to prevent the balance weight main body 6 from rotating when the rotor moves.

[0040] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com