Novel oblique grid-type duct collecting pipe

A technology of dust collecting pipe and dust collecting pipe, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of different working principles and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

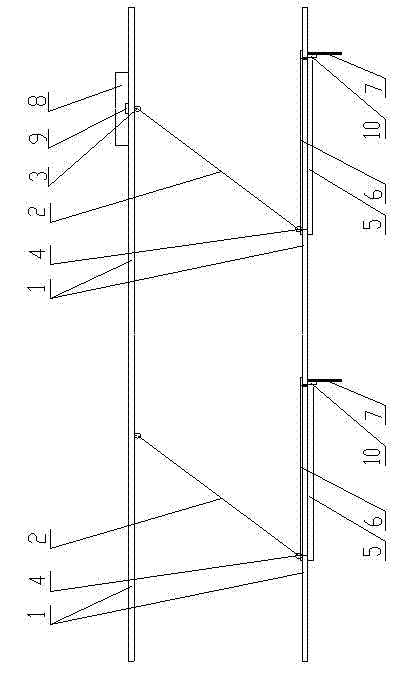

[0023] Take the 1#9200 dedusting equipment of Laiwu Steel Ironmaking Plant as an example, the total pressure of the dedusting fan: 4200Pa, and the processing air volume: 670000 m 4 / h, the diameter of the dust collection pipe is 1000 mm. According to the structure figure 1 Shown:

[0024] Firstly, the steel pipe material with a wall thickness of 5 mm and a diameter of 1000 mm is used to make a purification dust collection pipe, and the outlet is connected to the dust collection pipe of the dust collector; the upper part of the purification dust collection pipe 1 is welded with a hook 3 at an appropriate position on the inner wall of the pipe, and the lower part of the outlet is inclined at 45° The lower hook 4 is welded on the inner wall of the pipe; the lower part of the pipe body is an arc-shaped plate-shaped cleaning door 5 with a length of 1000 mm and an arc width of 500 mm from the lower hook to the upper hook. Available airtight dust-removing cloth bag 6 covers parcel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com