Installation structure for shaver and main shaft of gear shaving machine

An installation mechanism and a technology for a gear shaving machine, which are applied to gear cutting machines, components with teeth, gear teeth manufacturing devices, etc. and other problems, to achieve the effect of ensuring processing accuracy and durability, and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

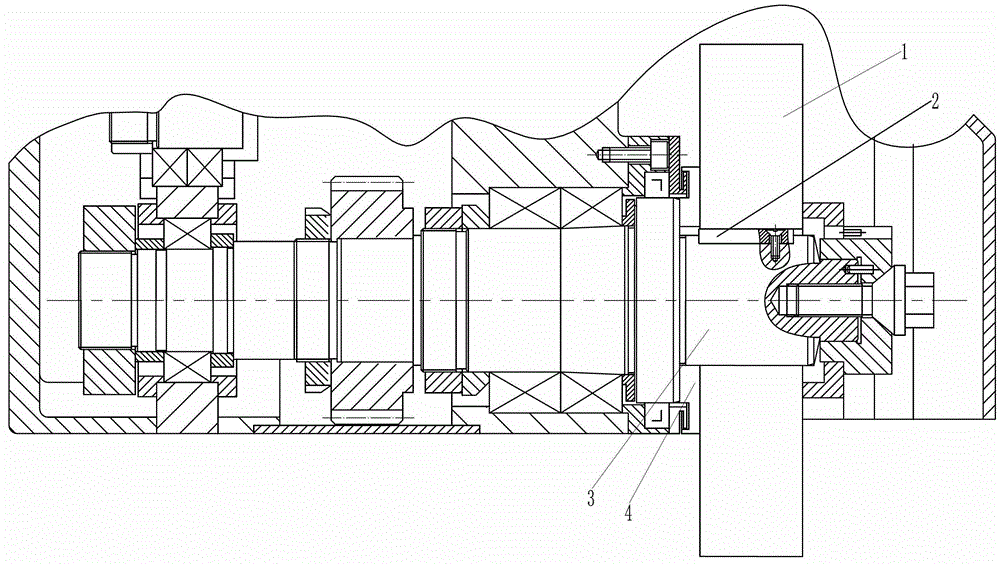

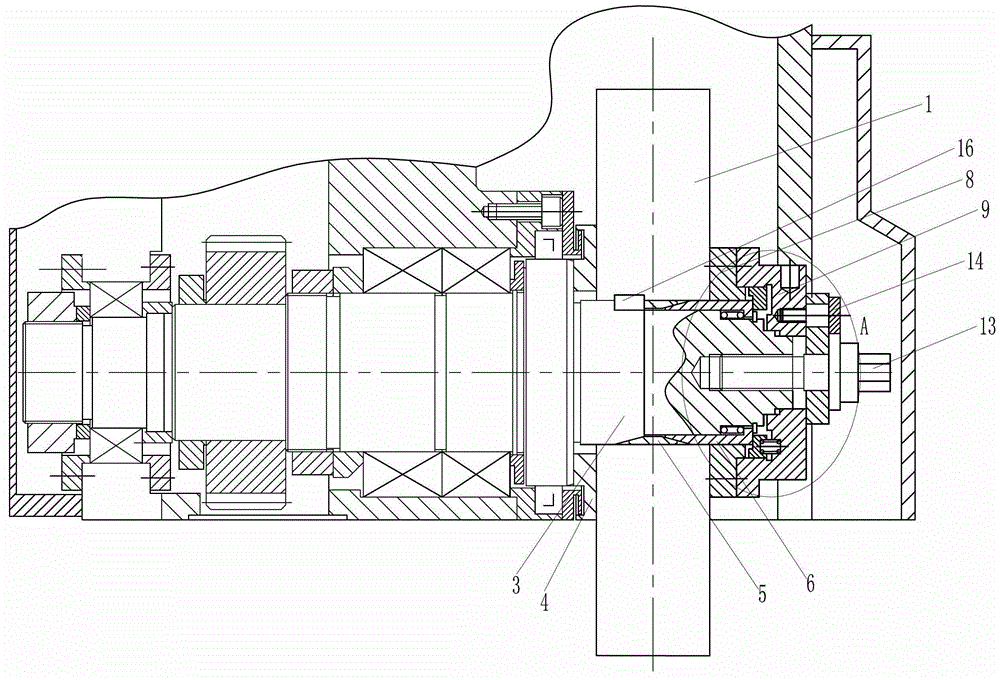

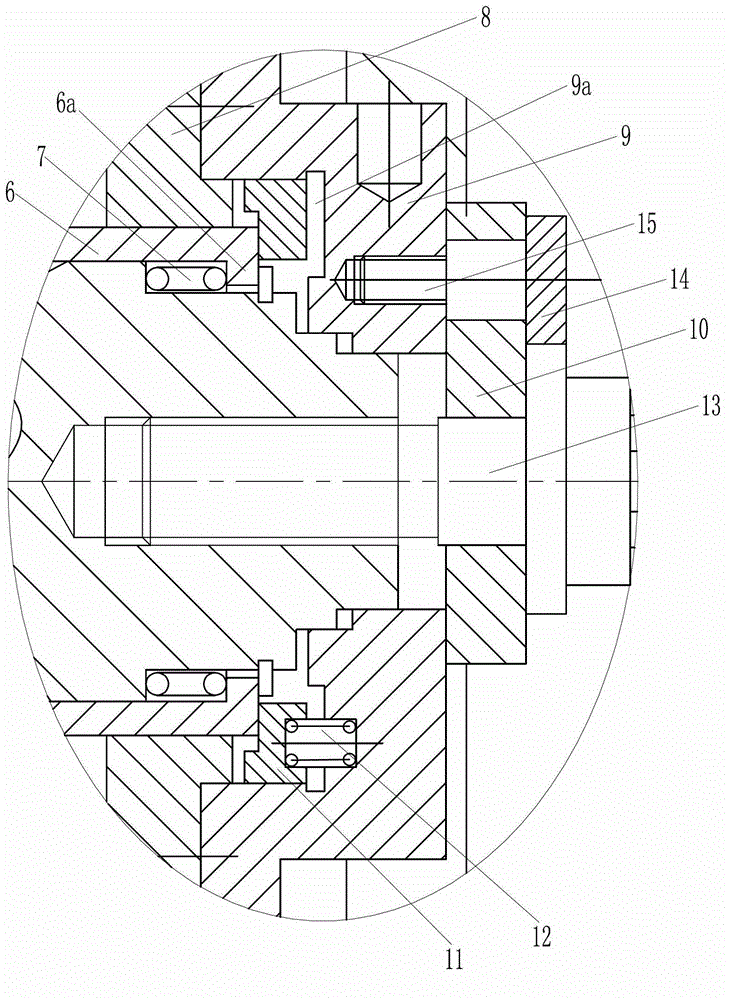

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0027] like figure 2 , 3 , 4 and 5, a gear shaving machine razor and the installation mechanism of the main shaft, mainly by the razor 1, main shaft 3, positioning sleeve 4, expansion sleeve 5, taper sleeve 6, return spring 7, locking mechanism and short key 16 constitute. Wherein the positioning sleeve 4 adopts a traditional structure, and the positioning sleeve 4 is fixedly sleeved on the right part of the main shaft 3 . The razor 1 basically adopts the existing structure, and the razor 1 is located on the right side of the positioning sleeve 4 . As an improvement point of the present invention, the razor 1 is set on the main shaft 3 through the expansion sleeve 5, the structure of the expansion sleeve 5 is basically the same as that of the existing expansion sleeve, and the right part of the expansion sleeve 5 is the expansion part. The left part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com